Multi-gear gearbox and control method thereof

A multi-speed transmission and shifting technology, which is applied in the direction of mechanical control devices, transmission device control, control/regulation systems, etc., can solve the problems of insufficient driving range of power batteries, low motor utilization efficiency, and low motor efficiency. The effect of simple structure, improved efficiency and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same or similar parts. The accompanying drawings are only used to illustrate the present invention, and do not represent the actual structure and true scale of the present invention.

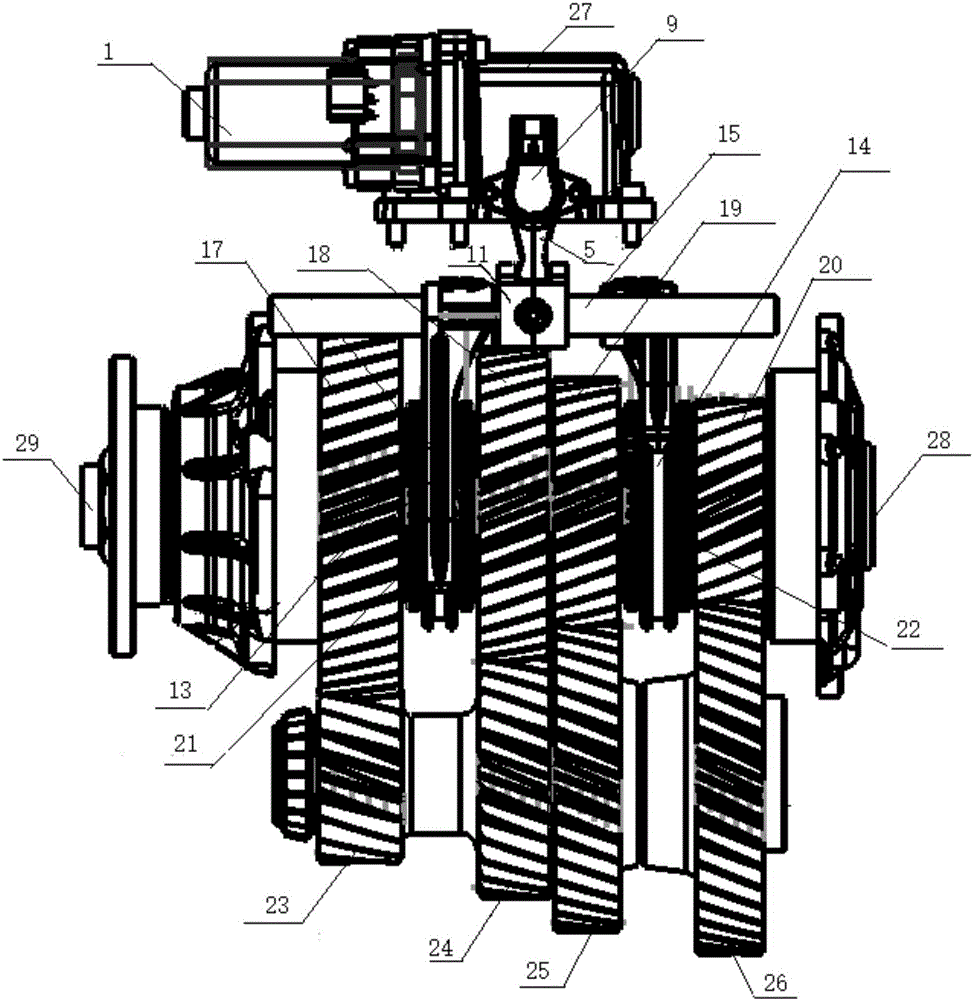

[0034] figure 1 Shown is an embodiment of the multi-speed transmission of the present invention, the multi-speed transmission includes a shift mechanism and an actuator.

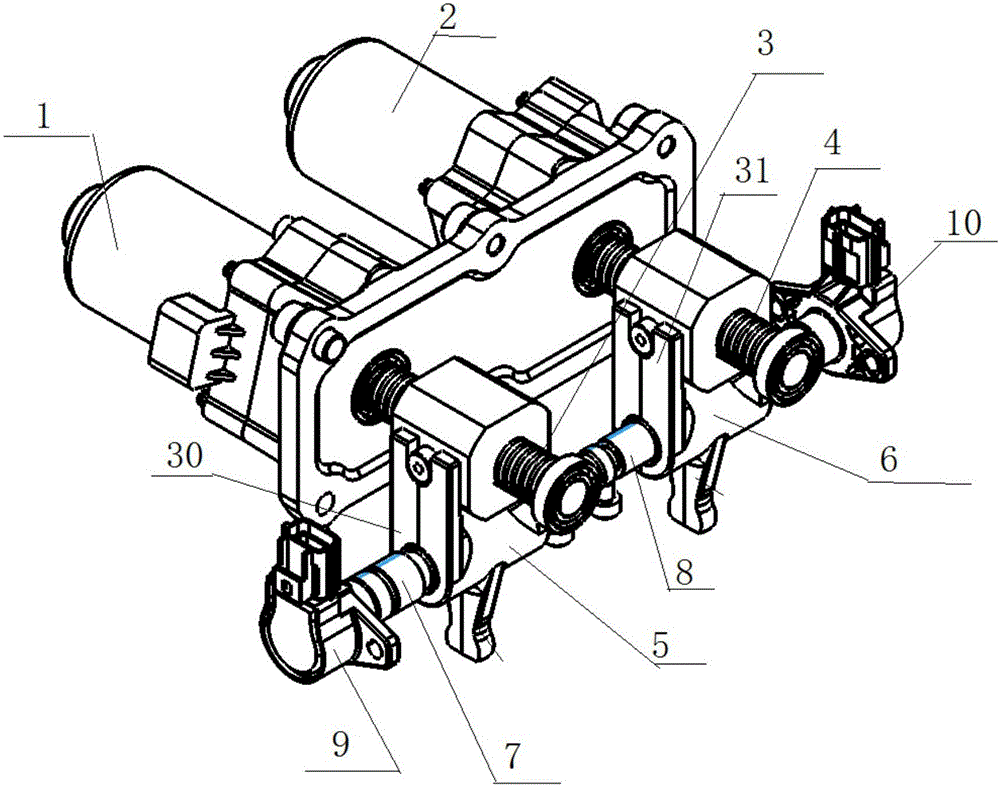

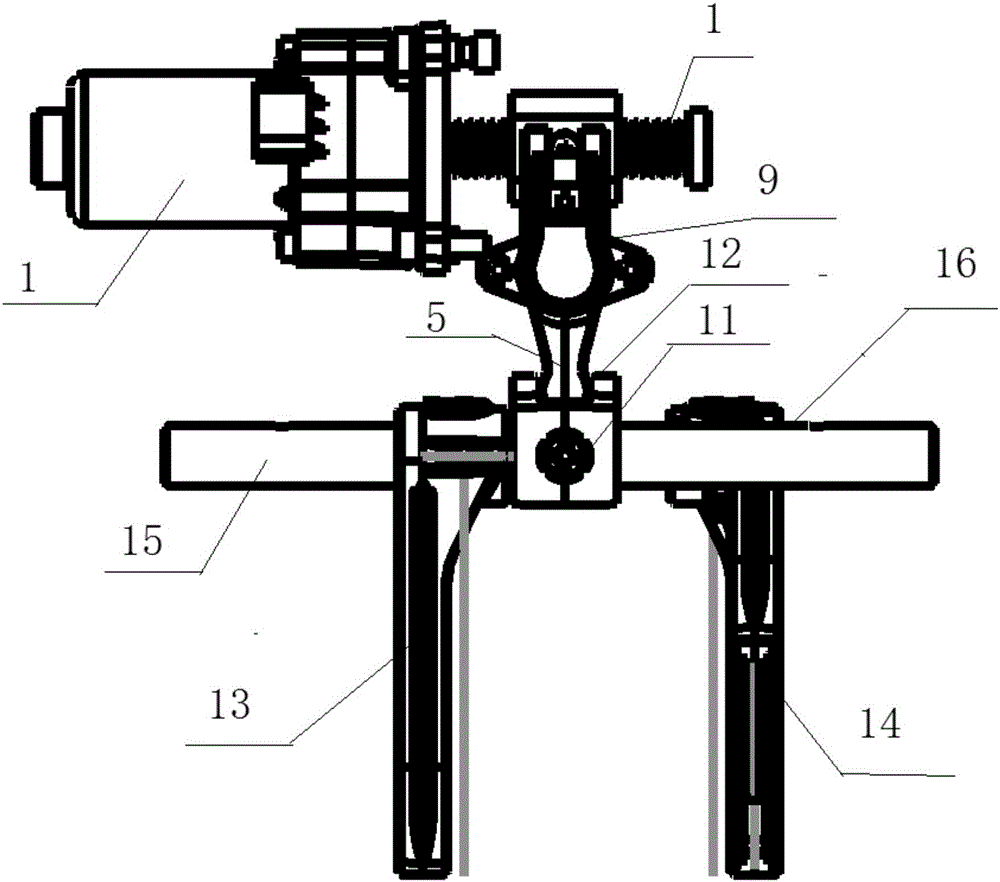

[0035] like figure 2 and image 3 As shown, the shift mechanism includes a first shift motor 1, a first roller screw 3, a first dial 5, a first shift shaft 7, a first sensor 9, a first guide block 11, a two Shift fork 13, first shift fork shaft 15, second shift motor 2, second roller screw 4, second dial 6, second shift shaft 8, second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com