Triaxial rheological testing apparatus and testing method of electro-hydraulic servo rock

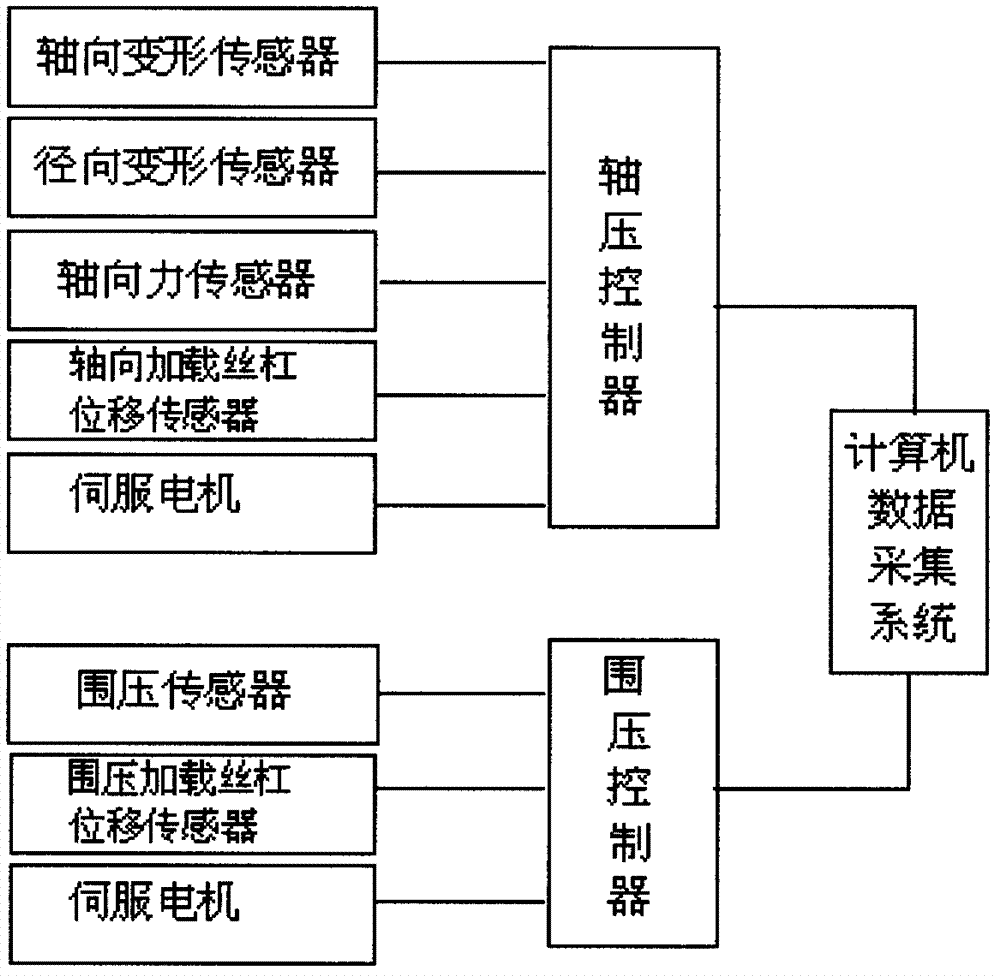

A three-axis rheological and electro-hydraulic servo technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of lack of precision in controlling and stabilizing voltage, and achieve good stability, convenient disassembly, and stable loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

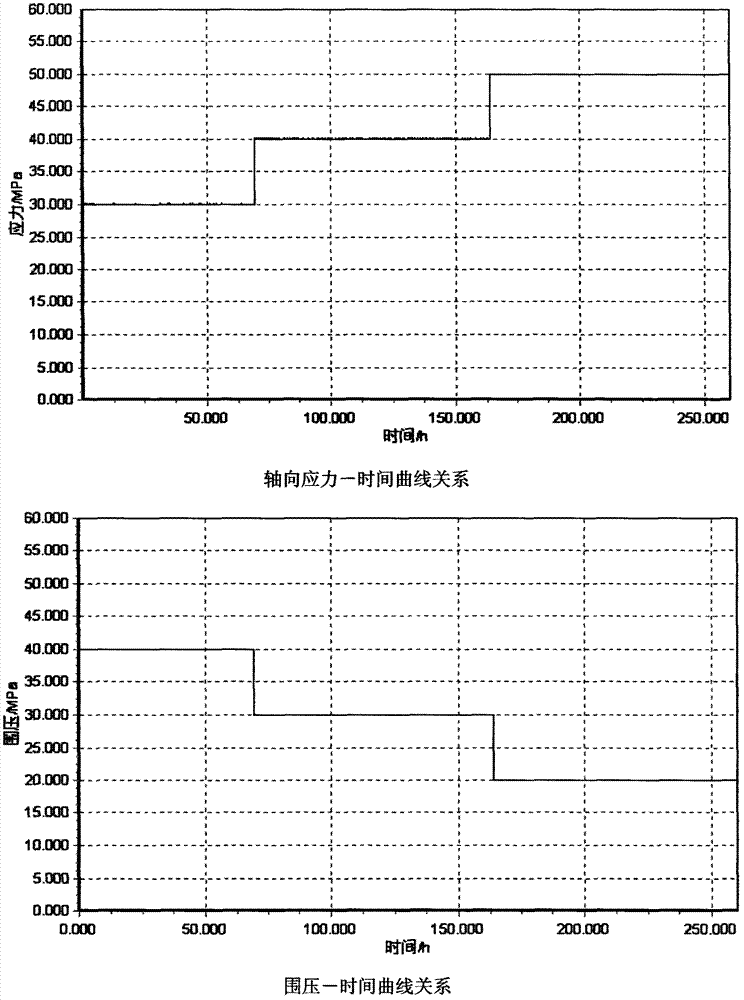

[0040] 1. Test conditions

[0041] The specimen is a cylindrical greenschist specimen with a diameter of 50 mm and a height of 100 mm. A triaxial rheological test scheme with stepwise loading of deviatoric stress was adopted. During the test, the confining pressure was unloaded step by step for 3 times, namely 40MPa, 30MPa and 20MPa.

[0042] 2. Test steps

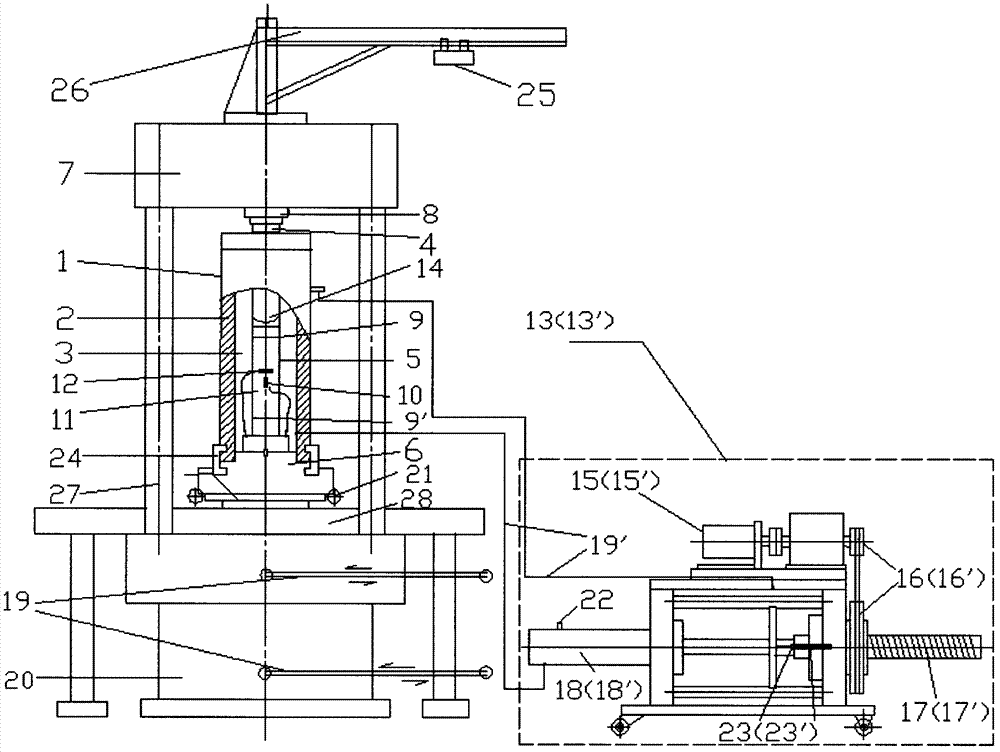

[0043] a) Install the lifting device, track and trolley, and fix the pressure chamber seat on the trolley. Lift the pressure chamber chamber, install and fix the test piece, fix the axial and radial sensor elements on the test piece, connect the lead wires, then drop the pressure chamber outside the pressure chamber, and put on the clamp.

[0044] b) When starting the liquid-filled oil source pump, start the servo motor at the same time to retract the roller screw of the pressurized cylinder; when the piston of the pressurized cylinder returns to the set position, turn off the liquid-filled oil source oil pump, open the...

Embodiment 2

[0048] 1. Test conditions

[0049] The specimen is a cylindrical greenschist specimen with a diameter of 50 mm and a height of 100 mm. A triaxial rheological test scheme with stepwise loading of deviatoric stress was adopted. During the test, the confining pressure was unloaded in three stages, namely 15MPa, 10MPa, 5MPa, and 2MPa; the axial force was correspondingly 20MPa, 55MPa, 60MPa, 65MPa, 70MPa, etc.

[0050] 2. Test steps

[0051] a) Install the lifting device, track and trolley, and fix the pressure chamber seat on the trolley. Lift the pressure chamber chamber, install and fix the test piece, fix the axial and radial sensor elements on the test piece, and connect the lead wires; then drop the pressure chamber outside and put on the clamp.

[0052] b) When starting the liquid-filled oil source pump, start the servo motor at the same time to retract the roller screw of the pressurized cylinder; when the piston of the pressurized cylinder returns to the set position, t...

Embodiment 3

[0056] 1. Test conditions

[0057] The specimen is a cylindrical greenschist specimen with a diameter of 100 mm and a height of 200 mm. A triaxial rheological test program was adopted to keep the confining pressure 15MPa constant and load the deviatoric stress step by step. During the test, the axial stress was loaded in three stages, 25MPa, 30MPa, and 35MPa respectively.

[0058] 2. Test steps

[0059] a) Install the lifting device, track and trolley, and fix the pressure chamber seat on the trolley. Lift the pressure chamber chamber, install and fix the test piece, fix the axial and radial sensor elements on the test piece, and connect the lead wires; then drop the pressure chamber outside and put on the clamp.

[0060] b) When starting the liquid-filled oil source pump, start the servo motor at the same time to retract the roller screw of the pressurized cylinder; when the piston of the pressurized cylinder returns to the set position, turn off the liquid-filled oil sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com