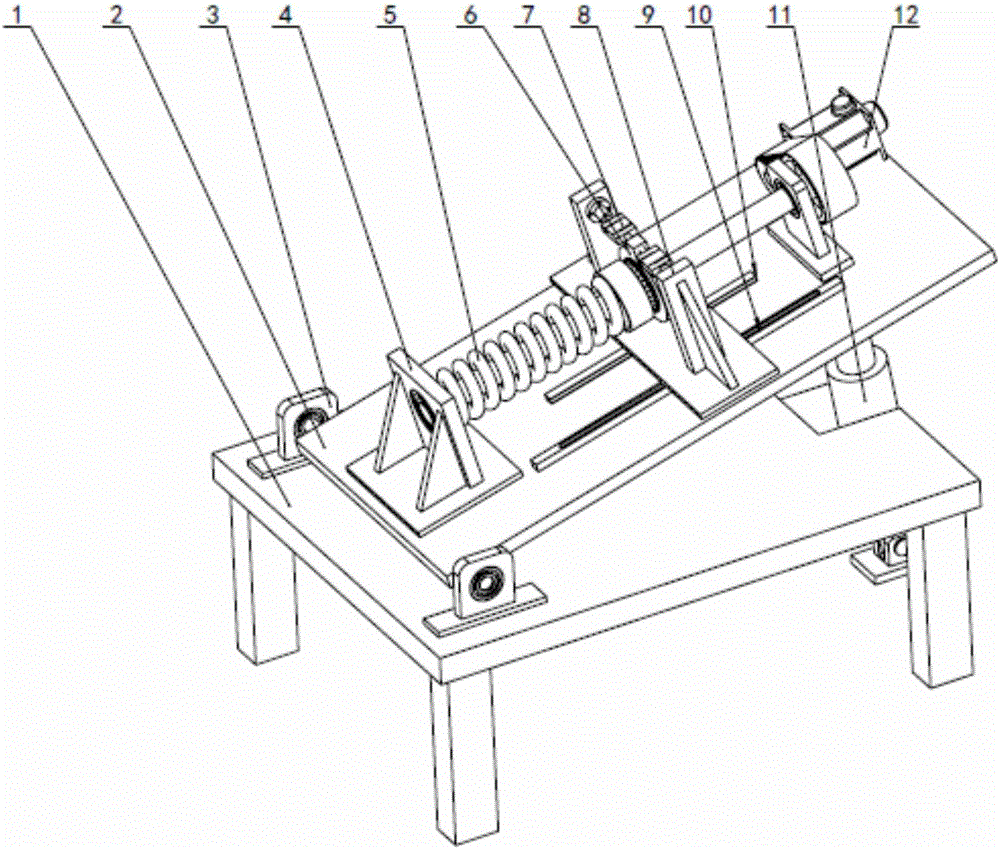

Planetary roller screw pair friction torque measurement device

A friction torque and planetary roller technology, which is applied in the field of measuring devices of planetary roller screw pairs, achieves the effect of strong versatility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

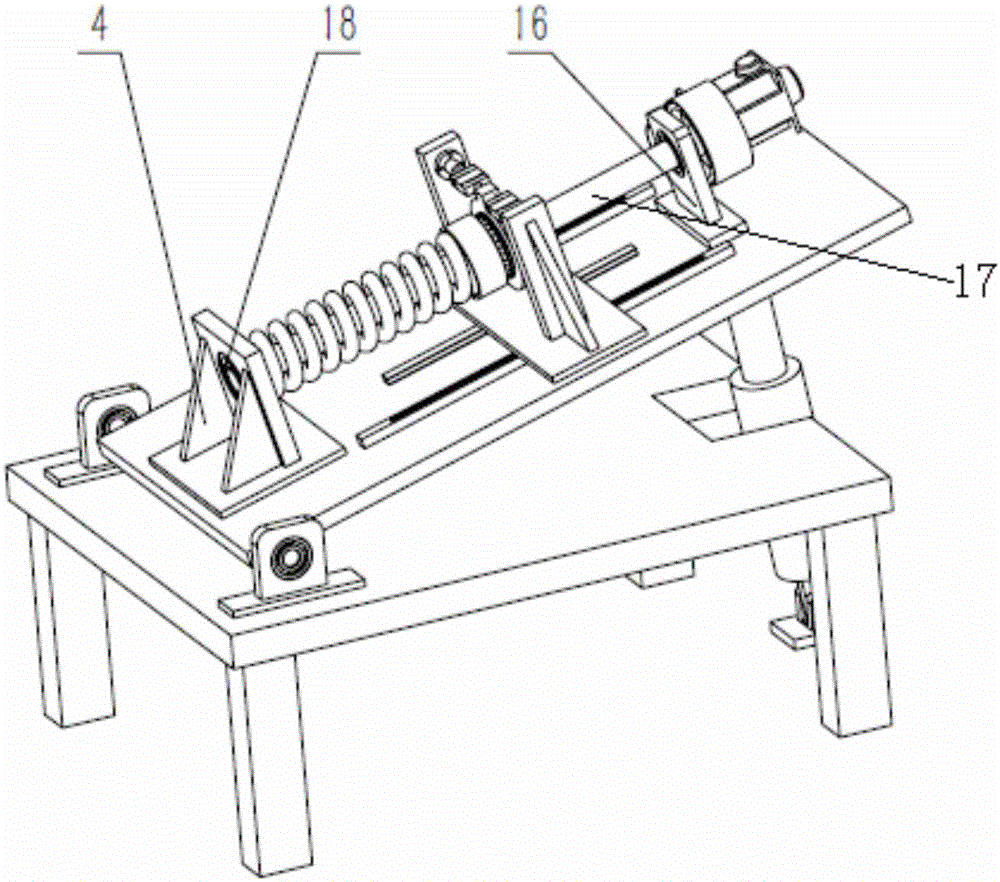

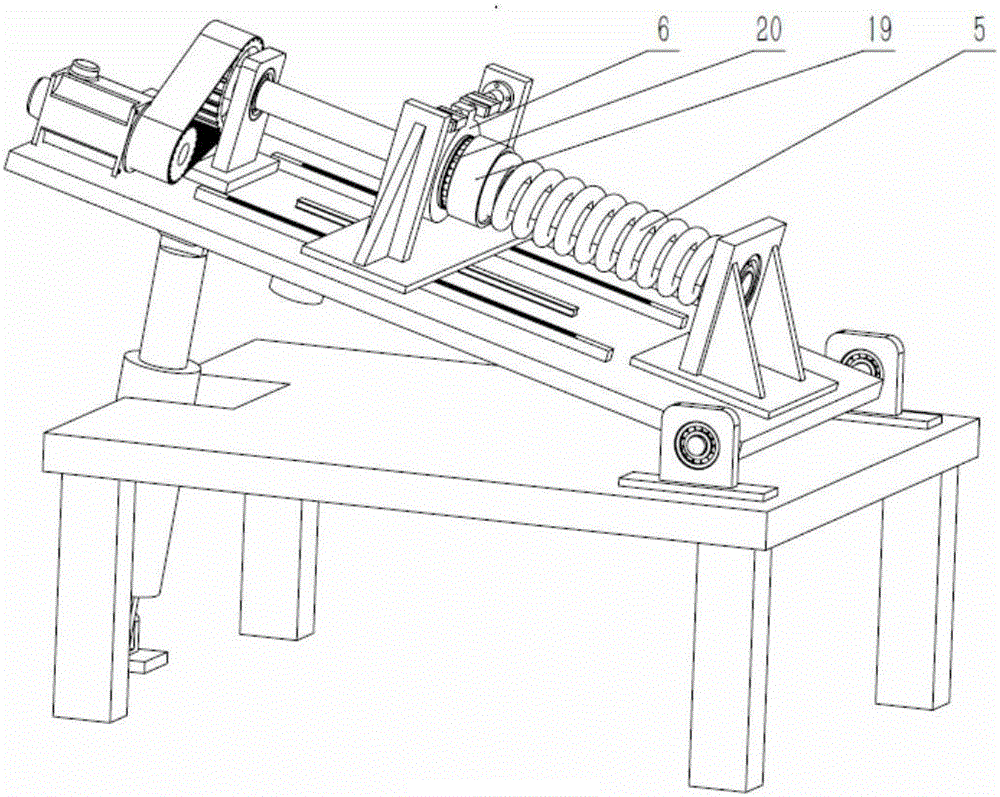

[0021] This embodiment is a measuring device for the friction torque of a planetary roller screw pair.

[0022] The working mode of the measuring device of the planetary roller screw pair friction torque in this embodiment:

[0023] At the beginning of the work, the planetary roller screw pair is placed on the bottom plate, and the inclination angle of the bottom plate is adjusted by a jack, thereby changing the inclination angle of the lead screw; then, it is kept at a fixed angle value. When the motor is turned on, the power is transmitted to the lead screw through the pulley mechanism. The lead screw rotates around its own axis and drives the nut to move linearly; when the nut moves linearly, it is loaded by a spring, and the nut not only moves linearly but also rotates itself. When the pull pressure sensor prevents it from rotating, the nut only keeps moving in a straight line without rotating itself. The force received by the pull pressure sensor to prevent the nut from r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com