High-power laser module and packaging method thereof

A laser module, high-power technology, used in lasers, laser parts, semiconductor lasers, etc., to avoid power loss, reduce costs, and solve thermal stress problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] like Figure 1-3 shown.

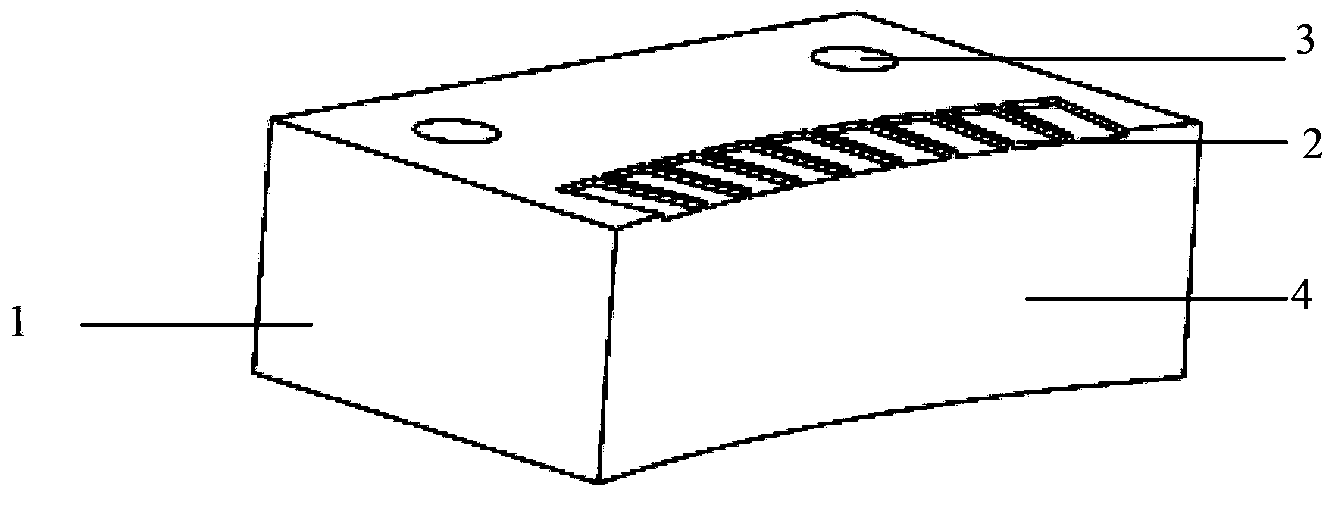

[0047] A high-power laser module, including a heat sink 1, on the surface of the heat sink 1, and on the side of the light output end, a plurality of series-connected laser single-tube chip units are arranged, and the plurality of series-connected laser single-tube chip units The chip units are arranged in an arc shape on the side of the light output end of the heat sink.

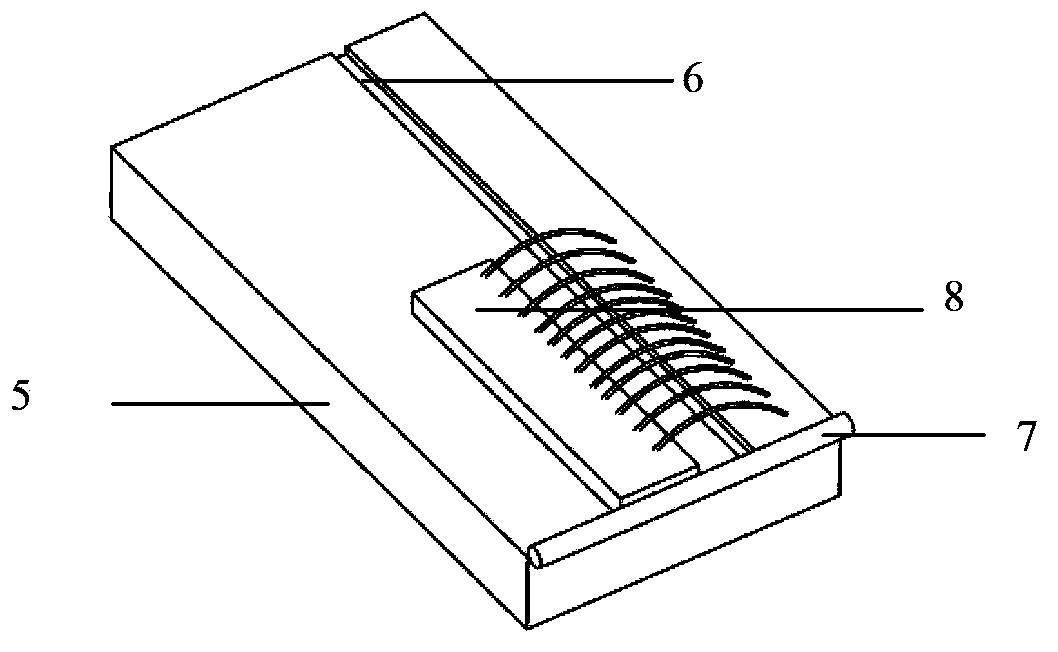

[0048] A fast-axis compressed cylindrical lens 7 is arranged at the light-emitting end of the laser single-tube chip unit, and the light spot adjustment of the laser single-tube chip unit in the direction of the fast axis is realized through fast-axis compression.

[0049] The laser single-tube chip unit is fixedly connected to the heat sink 1 through the first solder; the laser single-tube chip unit includes a metallized ceramic substrate 5, and an insulating groove 6 and a laser single-tube chip unit are arranged on the metallized ceramic substrate 5. The chip 8, the las...

Embodiment 2

[0055] A high-power laser module as described in Embodiment 1, the difference is that, on the surface of the heat sink 1 and on the side of the light output end, there is a unit positioning groove 2 for installing a laser single-tube chip unit, and the unit The size of the positioning groove 2 is adapted to the size of the laser single tube chip unit.

Embodiment 3

[0057] like Figure 4 , 5 shown.

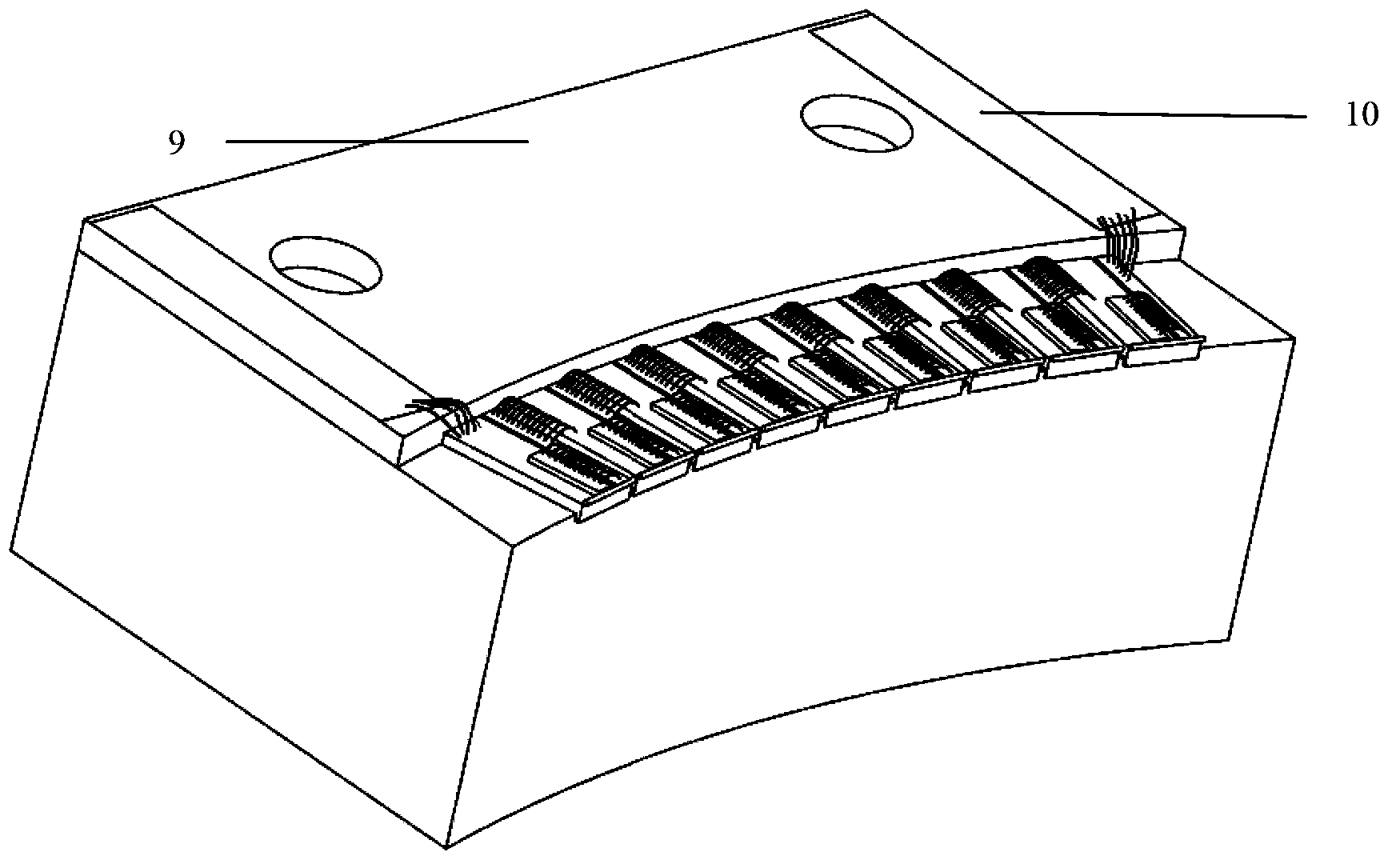

[0058] A high-power laser module as described in Embodiment 1, the difference is that the multiple series-connected laser single-tube chip units are arranged in an arc-shaped inscribed polyline on the side of the light-emitting end of the heat sink.

[0059] The light-emitting end surface of the heat sink is in the shape of an arc-shaped inscribed multi-segment line, and the shape and size of the light-emitting end face are adapted to the plurality of series-connected laser single-tube chip units arranged in an arc-shaped inscribed poly-segment line: The plurality of series-connected laser single-tube chip units are arranged along the arc-shaped inscribed multi-segment linear light-emitting end face.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com