Closed heat dissipating piece

A heat-dissipating, airtight technology, used in lighting and heating equipment, semiconductor devices for light-emitting elements, cooling/heating devices for lighting devices, etc. problems, to achieve the effect of prolonging life and preventing heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

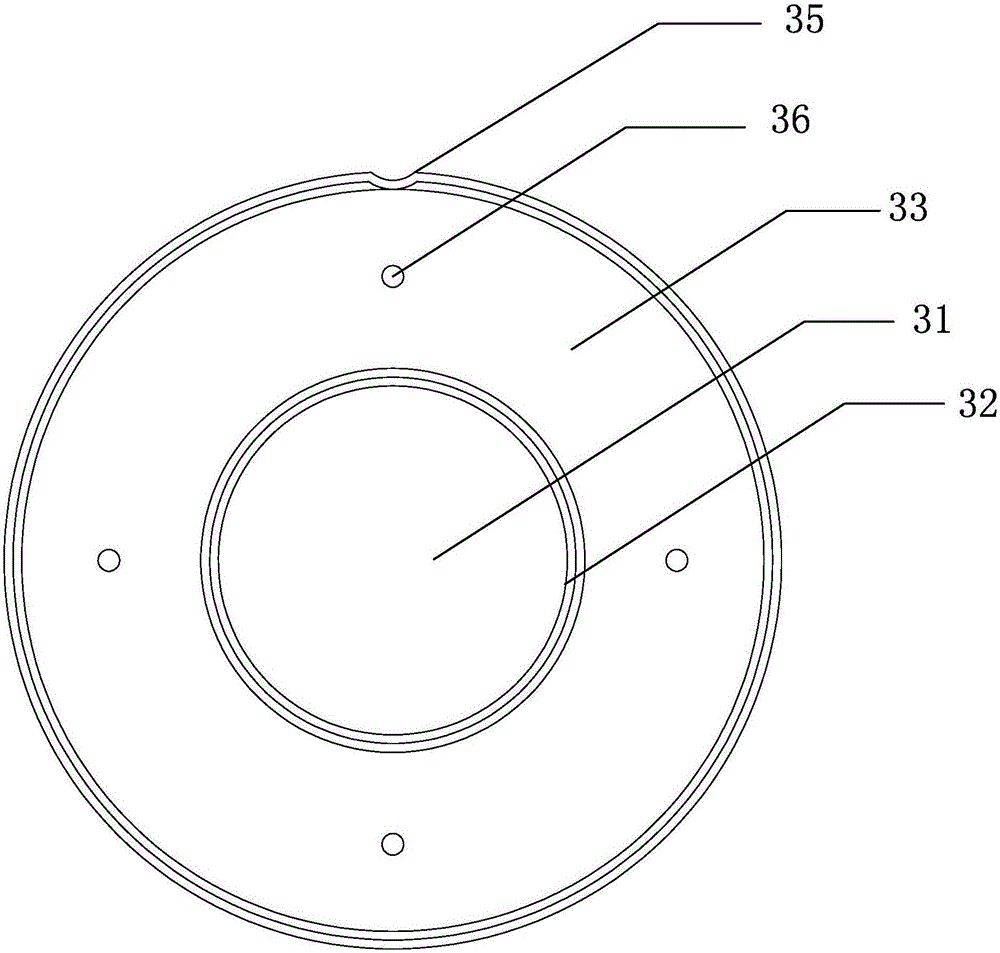

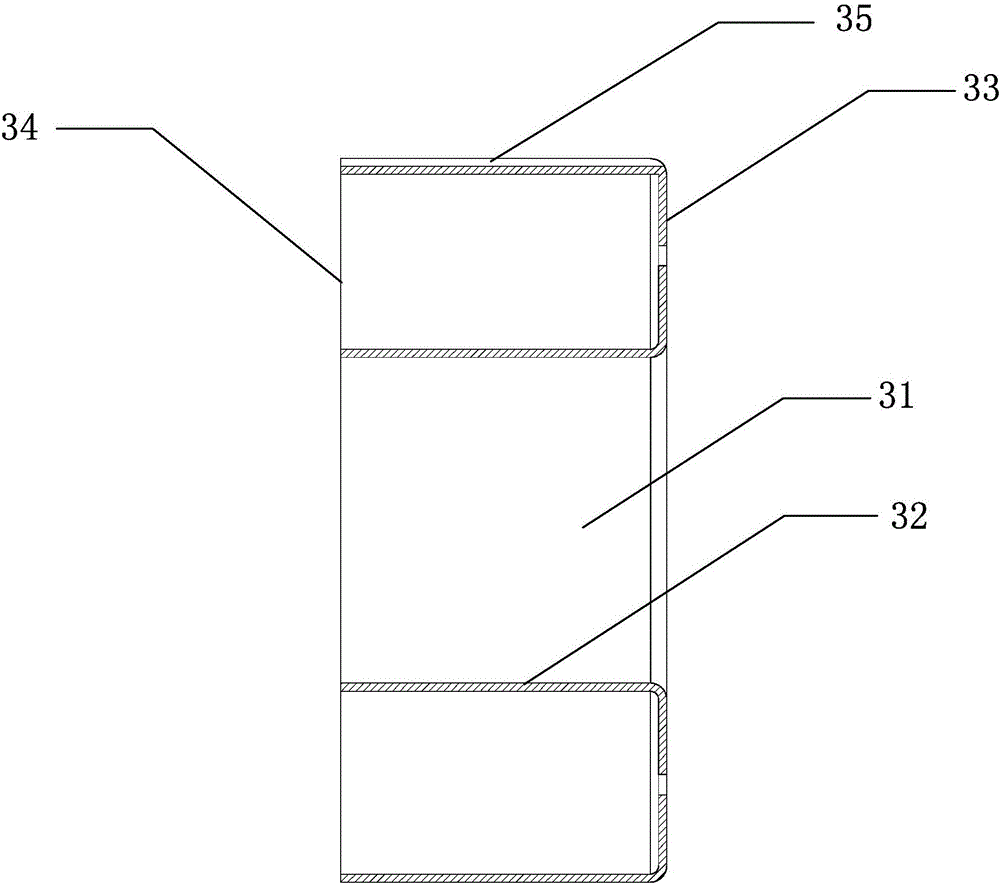

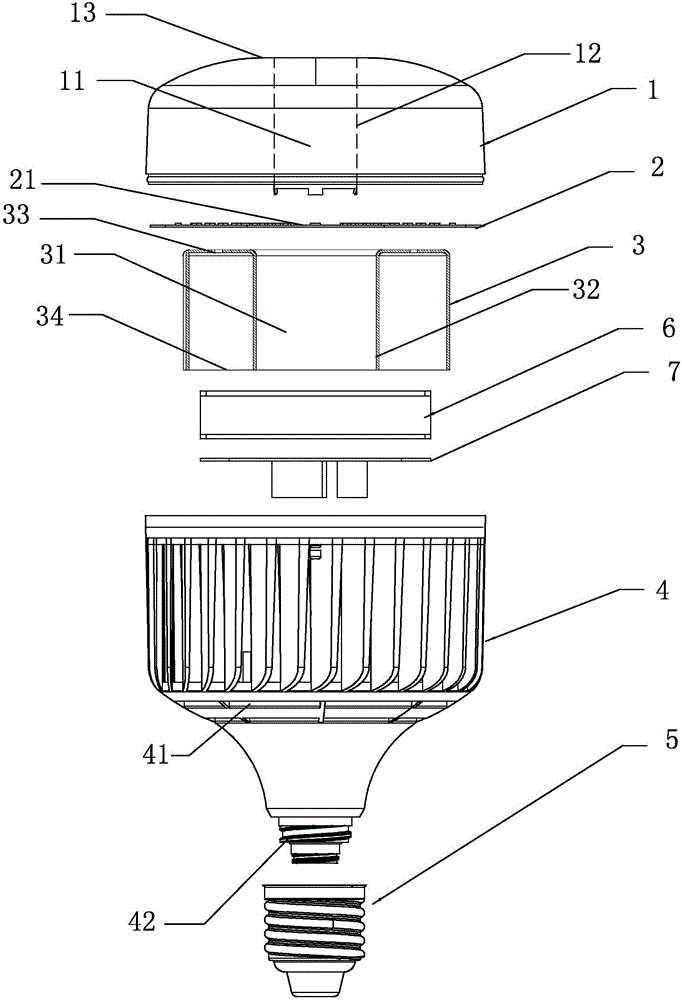

[0016] refer to figure 1 and 2 , a closed heat sink, comprising:

[0017] The upper surface 33 is used to absorb heat and support the LED light board,

[0018] The outer surface 35 is used to dissipate heat to the outside,

[0019] The inner surface 32 is arranged in the center of the heat sink 3 and combined with the upper surface 33 to form an air duct for air circulation,

[0020] Also includes an open lower surface 34, the junction of the upper surface 33 and the outer side 35 is an arc-shaped smooth connection, the junction of the upper surface 33 and the inner side 32 is an arc-shaped smooth connection, and the upper surface 33 center A through hole 31 is provided, and the through hole 31 is sunken inwardly and connected with the inner surface 32. Both the outer surface 35 and the inner surface 32 are surrounded to form a ring structure with closed side walls. The side is the outer surface 35 and the inner surface 32 to form the open lower surface 34, the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com