Integrated single-cabin heating regeneration denitration system special for waste gas of internal combustion engine and denitration method

A heating regeneration, integrated technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of cumbersome control, difficulty in adapting to the installation space, redundancy, etc., and achieve simple and flexible devices, small footprint, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

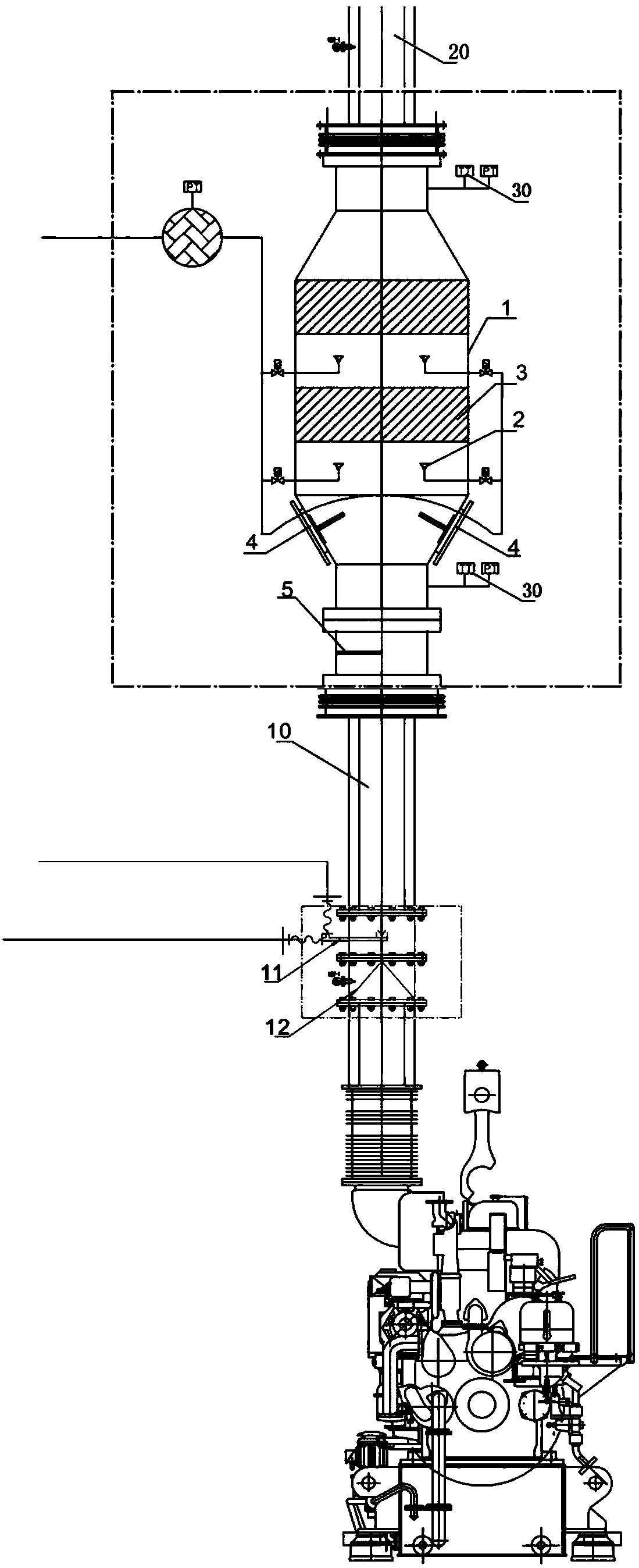

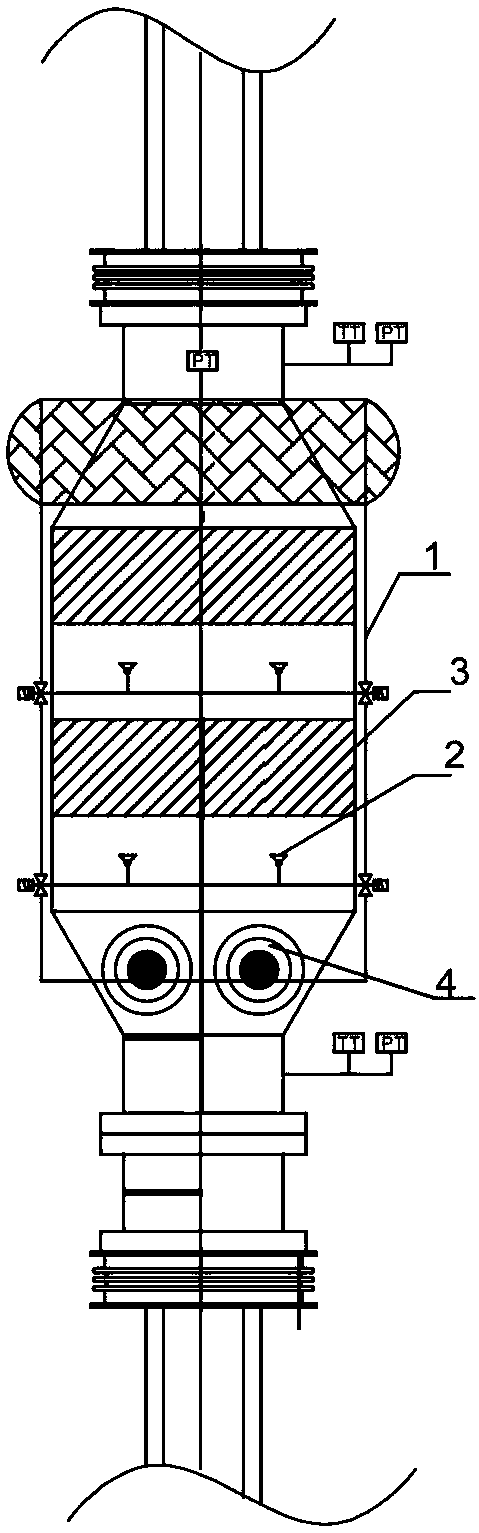

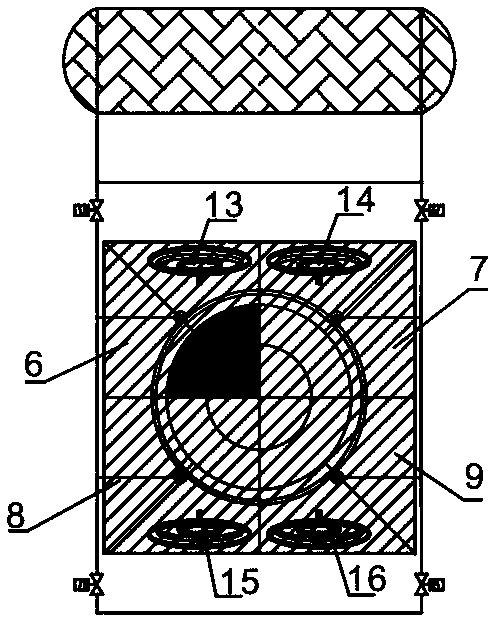

[0021] In order to make the system and method described in the present invention clearer, the following will be further described in detail in conjunction with specific implementation examples, such as figure 1 - image 3 As shown, the present invention provides an integrated single-chamber heating regeneration denitrification system dedicated to exhaust gas of an internal combustion engine: it is characterized in that it includes: a denitrification reactor 1, a main intake pipeline 10 connected to the internal combustion engine, and a gas outlet main pipe connected to the denitrification reactor 1 Road 20, the denitration reactor 1 is divided into four reactor compartments, the denitration reactor 1 is equipped with a soot blower 2 and a denitration catalyst 3, and the denitration reactor 1 is also provided with 4 maintenance doors 4 , the denitrification reactor 1 is provided with a pressure transmitter 30 at the junction of the main intake pipeline 10 and the main outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com