Multi-unit pipe type direct-current steam generator

A steam generator, multi-unit technology, applied in steam generation, steam generation methods, steam boilers, etc., can solve the problems of large occupied space and large overall volume, and can solve the difference of thermal expansion, reduce the heat transfer area, and improve the exchange rate. The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

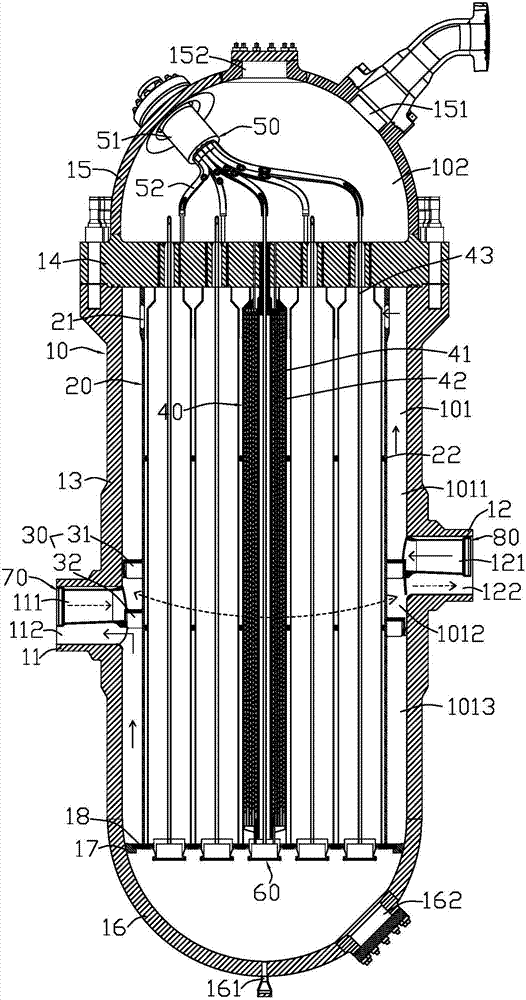

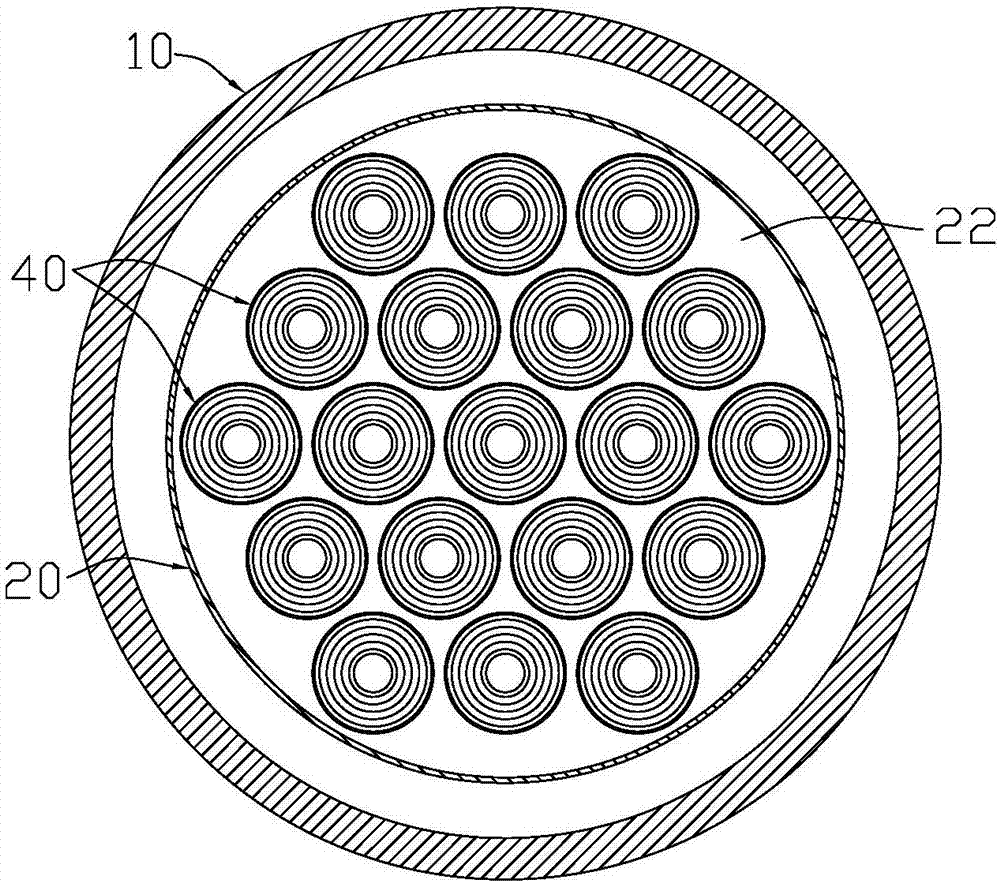

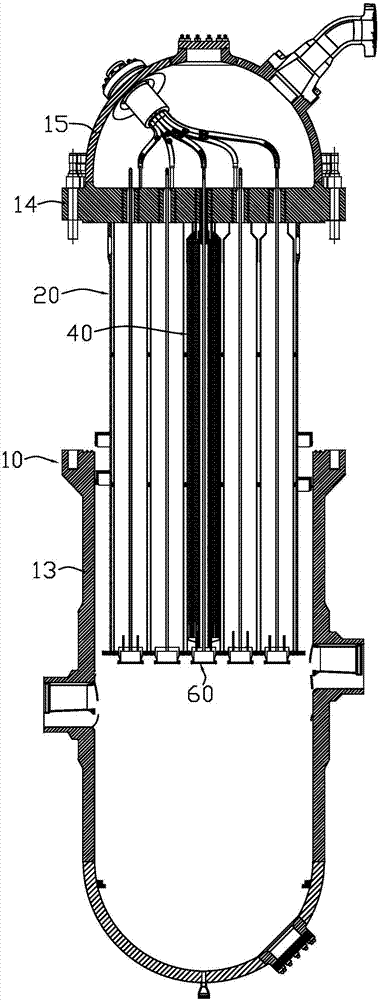

[0032] Such as figure 1 As shown, the multi-unit tubular once-through steam generator according to an embodiment of the present invention includes a closed container body 10 , a sleeve 20 disposed in the container body 10 , a partition assembly 30 and a plurality of heat exchange units 40 . Wherein, a chamber 101 is formed between the sleeve 20 and the inner wall of the container body 10 ; the partition assembly 30 is disposed in the chamber 101 , and divides the chamber 101 into an upper chamber 1011 and a lower chamber 1013 . A plurality of heat exchange units 40 are longitudinally arranged inside the sleeve 20 .

[0033] The side of the container body 10 is provided with a first nozzle 11 and a second nozzle 12; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com