A thermal treatment method for a solar battery encapsulating adhesive film

A heat treatment method and packaging film technology, applied in the field of heat treatment, can solve problems such as high energy consumption, high temperature, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

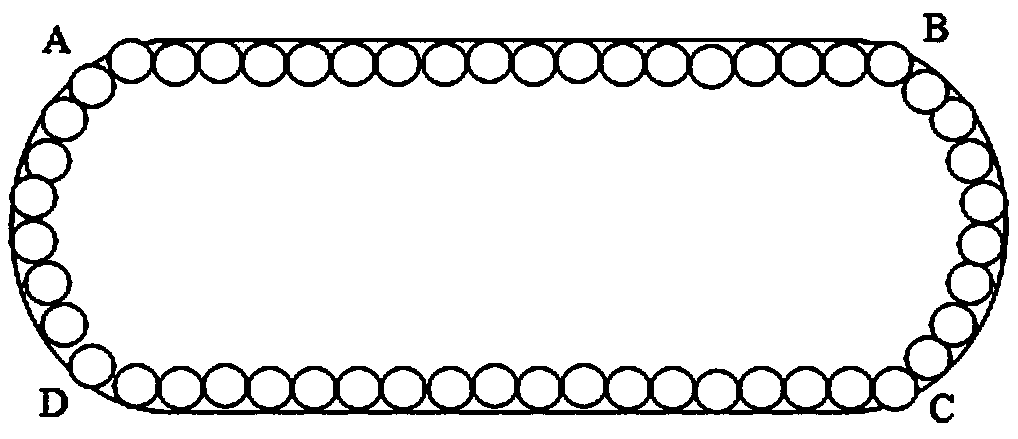

[0025] Embodiment 1: As shown in the figure, a heat treatment method of a solar cell encapsulation adhesive film is carried out according to the following steps:

[0026] Using constant temperature and cooling shaping section processing:

[0027] The outer ring is covered with a 1mm rubber transmission belt;

[0028] A heat transfer medium with stable heat conduction can be added in the rubber to ensure the heat transfer effect;

[0029] A small temperature-controlling roller with water of different temperatures or heat-conducting oil-related heat-conducting medium is passed into the inner ring to control the temperature of the veneer and keep the rubber in a tensioned state;

[0030] Different gradient temperature control is used to ensure that the film can be well maintained in the extrusion heating state, and at the same time, it can be well cooled and shaped in the subsequent cooling process;

[0031] A is where the adhesive film is attached to the tape, the conveyor bel...

Embodiment 2

[0035] Embodiment 2: a kind of heat treatment method of solar cell encapsulating adhesive film, carry out according to the following steps:

[0036] Using constant temperature and cooling shaping section processing:

[0037] The outer ring is covered with a 3mm rubber transmission belt;

[0038] A heat transfer medium with stable heat conduction can be added in the rubber to ensure the heat transfer effect;

[0039] A small temperature-controlling roller with water of different temperatures or heat-conducting oil-related heat-conducting medium is passed into the inner ring to control the temperature of the veneer and keep the rubber in a tensioned state;

[0040] Different gradient temperature control is used to ensure that the film can be well maintained in the extrusion heating state, and at the same time, it can be well cooled and shaped in the subsequent cooling process;

[0041] A is where the adhesive film is attached to the tape. The conveyor belt A~B area is a temper...

Embodiment 3

[0045] Embodiment 3: A kind of heat treatment method of solar cell encapsulation adhesive film, carry out according to the following steps:

[0046] Using constant temperature and cooling shaping section processing:

[0047] The outer ring is covered with a 5mm rubber transmission belt;

[0048] A heat transfer medium with stable heat conduction can be added in the rubber to ensure the heat transfer effect;

[0049] A small temperature-controlling roller with water of different temperatures or heat-conducting oil-related heat-conducting medium is passed into the inner ring to control the temperature of the veneer and keep the rubber in a tensioned state;

[0050] Different gradient temperature control is used to ensure that the film can be well maintained in the extrusion heating state, and at the same time, it can be well cooled and shaped in the subsequent cooling process;

[0051] A is where the adhesive film is attached to the tape. The conveyor belt A~B area is a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com