Composite heat sink material with thermal expansion coefficients in gradient distribution and preparation method thereof

A technology of thermal expansion coefficient and heat sink material, which is applied in the direction of electrical components, circuits, electric solid devices, etc., can solve the problems of reducing connection interface power semiconductor devices, thermal expansion coefficient mismatch, etc., to improve reliability and quality stability, eliminate Interface thermal resistance, effect of relieving thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

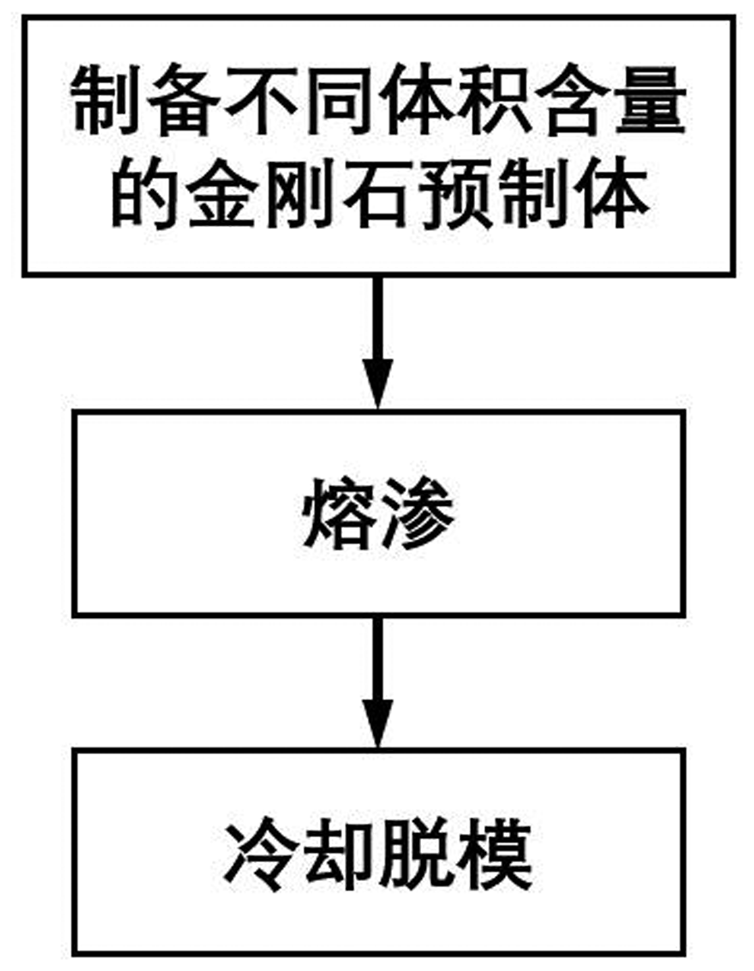

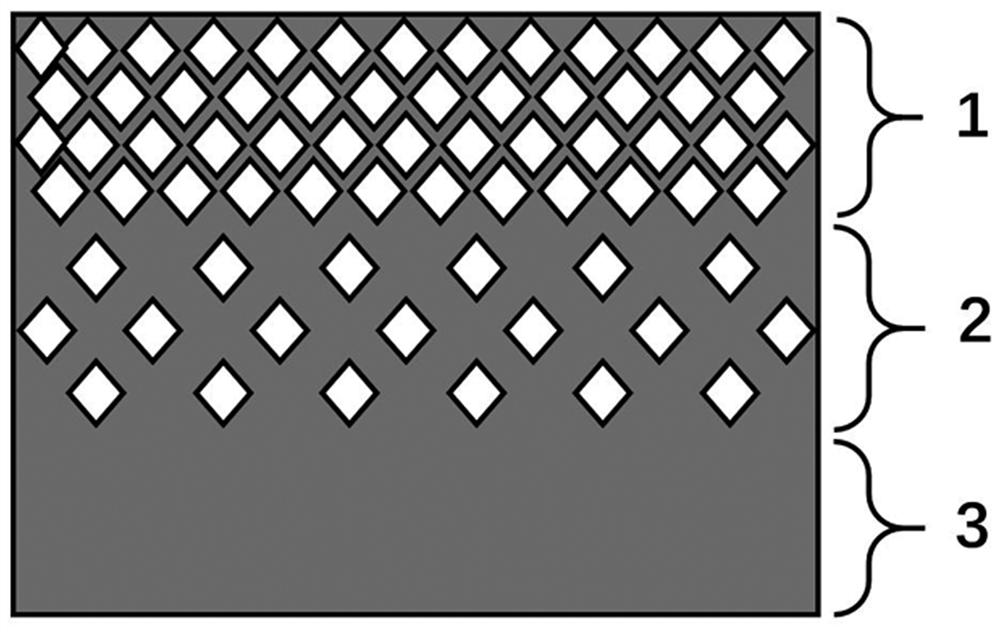

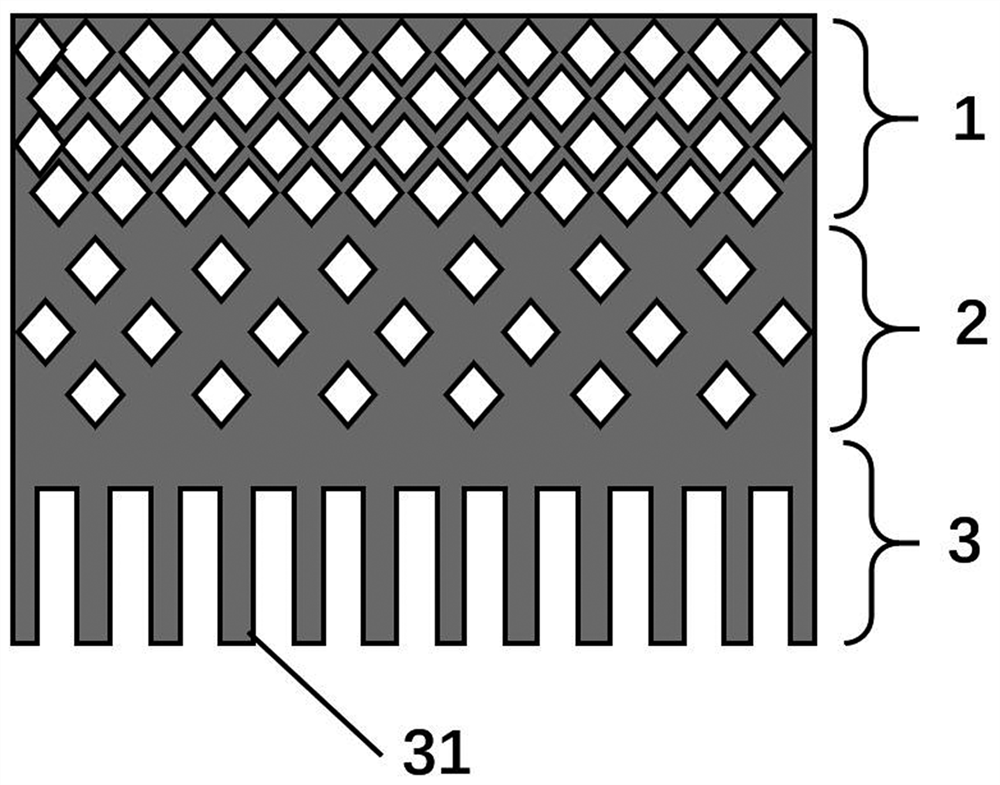

[0024] use figure 1 The process flow shown produces a composite heat sink material with a gradient distribution of thermal expansion coefficients. The specific process is as follows: the first step is to prepare diamond preforms with different volume contents: a layer of tungsten with a thickness of 180 nm is coated on the surface of the diamond with a particle size of 100 μm as an interface layer, and then the polyvinyl alcohol aqueous solution and different quantities of coated diamond are respectively After uniform mixing, the first green compact and the second green compact with a volume content of 60% and 32% diamond were obtained, and the dimensions were 20×20×3 and 20×20×2, respectively. The first and second diamond preforms with different volume fractions and certain strengths are obtained by drying and degreasing and strengthening respectively; the second step, infiltration: according to the second diamond preform, the first diamond preform is at the bottom and the fi...

Embodiment 2

[0027] use figure 1 The process flow shown produces a composite heat sink material with a gradient distribution of thermal expansion coefficients. The specific process is as follows: the first step is to prepare diamond preforms with different volume contents: 1000nm-thick silicon and 430nm-thick titanium are respectively plated on the surface of diamond with a particle size of 300μm and 500μm as an interface layer, and then paraffin and different amounts of The coated diamonds were uniformly mixed and then pressed to form the first and second green compacts with a diamond volume content of 80% and 40%, respectively, and the sizes were Ф50×2 and Ф50×3. Degreasing and strengthening are carried out by drying respectively to obtain a first diamond preform and a second diamond preform with different volume fractions and a certain strength; the second step, infiltration: according to the second diamond preform at the bottom and the first diamond preform at the bottom The above seq...

Embodiment 3

[0030] use figure 1 The process flow shown produces a composite heat sink material with a gradient distribution of thermal expansion coefficients. The specific process is as follows: the first step is to prepare diamond preforms with different volume contents: 200nm thick boron and 510nm thick molybdenum are respectively plated on the diamond surface with a particle size of 10μm and 50μm as the interface layer, and then the phenolic resin aqueous solution is mixed with different A number of coated diamonds were uniformly mixed and then pressed into shape to obtain the first and second green compacts with a diamond volume content of 40% and 10%, respectively, with dimensions of 8×4×1 and 8×4×1.5. Drying at a temperature of 230°C for degreasing and strengthening, respectively, to obtain a first diamond preform and a second diamond preform with different volume fractions and a certain strength; the second step, infiltration: according to the second diamond preform in the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com