Optical glass having high refractive index

A technology of optical glass and refractive index, which is applied in the field of precision molding optical glass, and can solve the problems of poor transmittance inside the glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

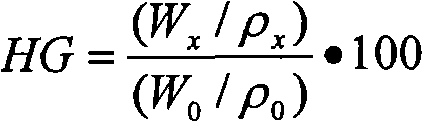

Method used

Image

Examples

Embodiment

[0080] Table 1 contains examples of embodiments within preferred compositional ranges. The glasses described in the examples were prepared according to the following instructions.

[0081] The raw materials of the various oxides were weighed and then they were thoroughly mixed. The glass mixture is melted at 1300-1400°C into a continuous molten aggregate. At the proper casting temperature, the glass can be cast and processed to the desired size.

[0082] Table 1: Examples 1 to 8 (expressed in % by weight based on the weight of the oxide)

[0083]

[0084]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com