Special single-bin heating regeneration denitration system for low-temperature flue gas, and denitration method

A heating regeneration, low-temperature flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of high operating costs, blocked catalysts, low temperature of coke oven flue exhaust gas, etc., and achieves a small footprint. , Simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

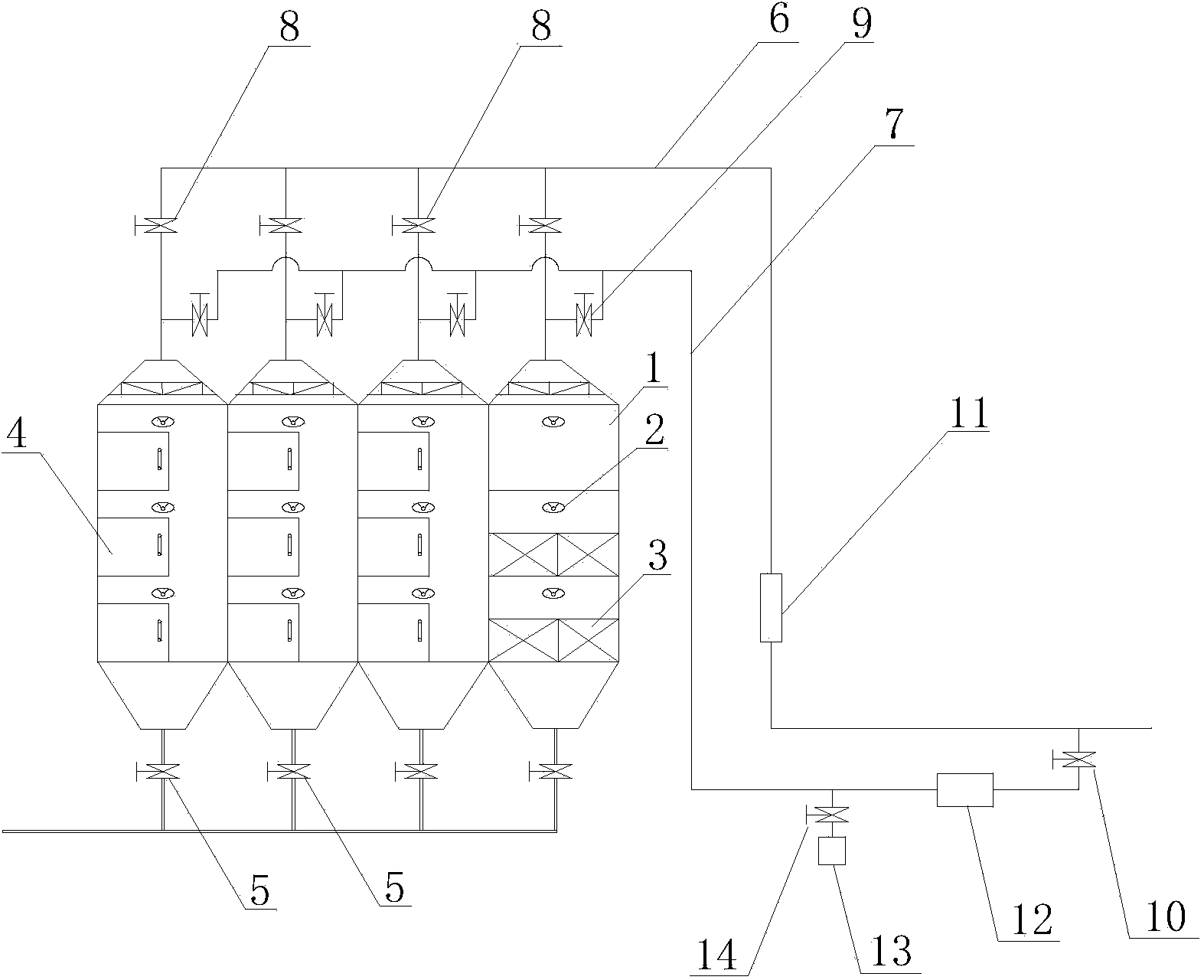

[0023] Embodiment: The structure system of the single-chamber heating regeneration denitrification system dedicated to low-temperature flue gas in this embodiment is:

[0024] A plurality of denitration reactors 1 are arranged side by side, each reactor is provided with a soot blower 2 and a denitration catalyst 3, a first butterfly valve 5 is provided in the exhaust pipeline at the bottom of each reactor, and each reactor is provided with an inspection door 4; The inlet and outlet of each reactor are equipped with differential pressure transmitters, which are used to detect the pressure difference between the inlet and outlet of the reactor and transmit the signal to the control system. Among them, the denitrification catalyst is a low-temperature anti-sulfur catalyst, such as vanadium-titanium series (TiO 2 As the main carrier, V 2 o 5 as the main active ingredient, and contains a small amount of heavy metals).

[0025] The first main air intake pipeline 6 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com