System and method for creating liquid droplet impact forced collapse of laser nanoparticle nucleated cavities

a laser nanoparticle and nucleated cavity technology, applied in nuclear targets, nuclear reactors, greenhouse gas reduction, etc., can solve the problems of acoustic inertial confinement fusion not winning widespread credibility, a large amount of energy, control loss, etc., to enhance the implosion energy of the cavity collapse, the effect of enhancing the collapse energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

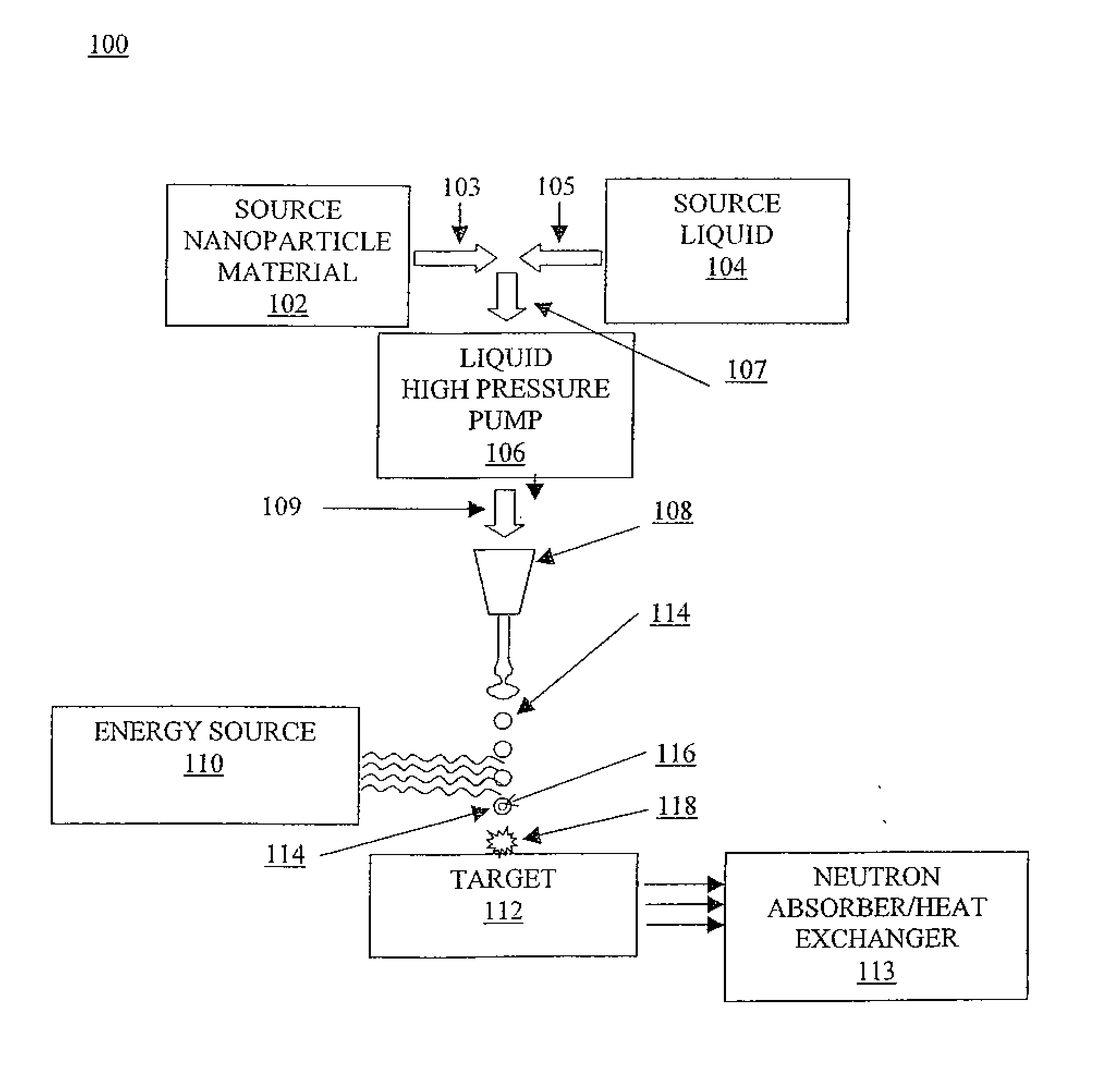

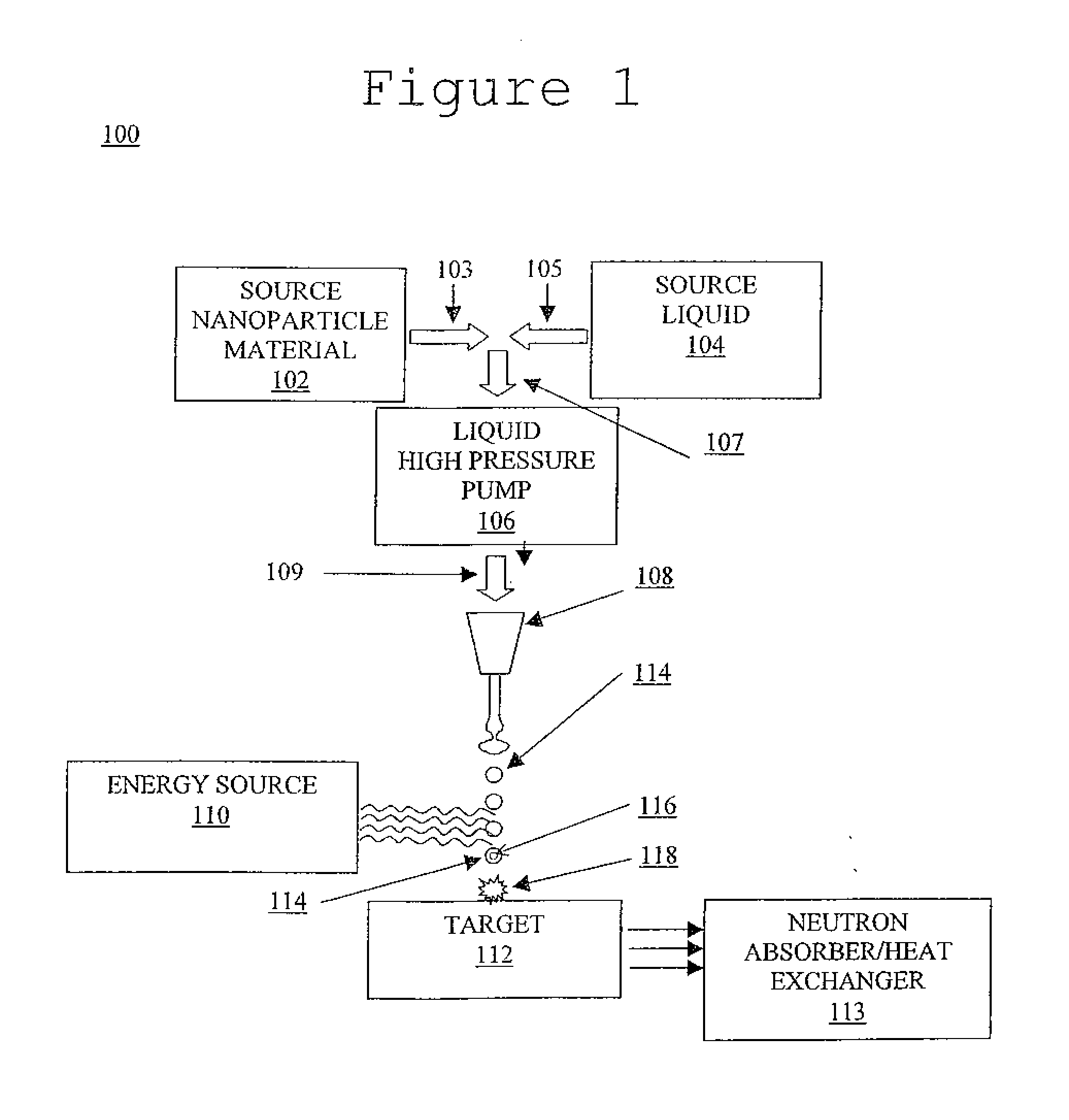

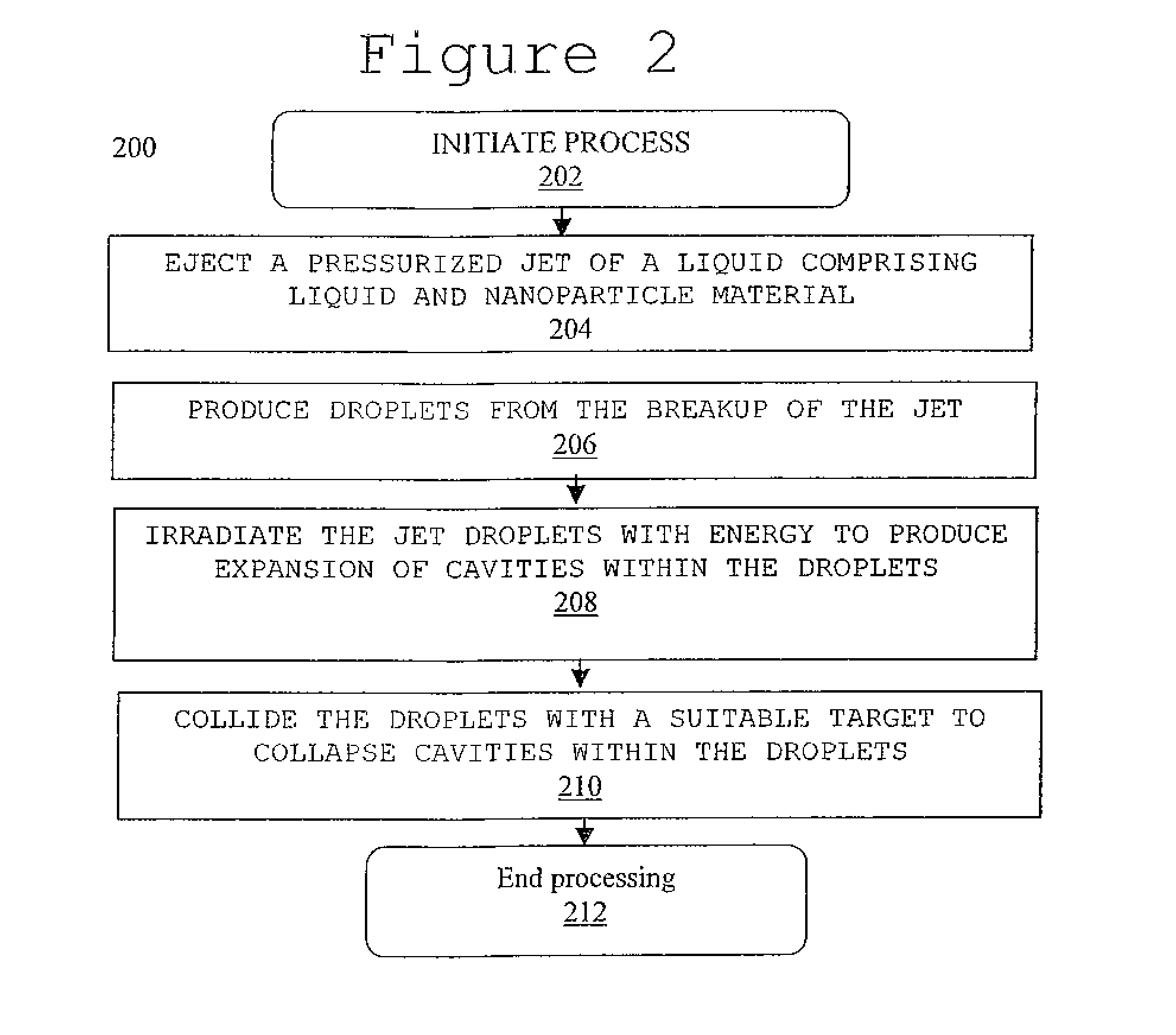

[0021]The invention disclosed herein rests in the union of two different technologies. The first technology relates to creating temporally, spatially and energetically controlled cavities in a liquid. The second technology relates to creating small, high-velocity droplets as disclosed, for example, in co-pending U.S. patent application Ser. No. 11 / 075,833 incorporated fully herein by reference. By combining these two technologies, cavities can be induced in high-velocity droplets with precise timing of their inception and expansion to a preferred radius. Upon impact of these cavity-containing droplets with a target, strong compressional waves are created which then rapidly propagate into the interior of the drop. Rapid inertial collapse of a cavity will be forced by the great positive pressure rise across the compressional wave, driving the cavity to collapse more violently than it would naturally. With suitable materials comprising the contents of the cavity, the energy during the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com