Method for improving integrated reliability of nuclear power station safety injection system

A reliable, pressurized water reactor nuclear power plant technology, applied in the direction of nuclear power generation, climate sustainability, nuclear engineering, etc., can solve the problems of large evaporation, frequent water replenishment, and high I0 consumption, so as to reduce the low temperature alarm value and improve power generation Efficiency, elimination of O&M effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

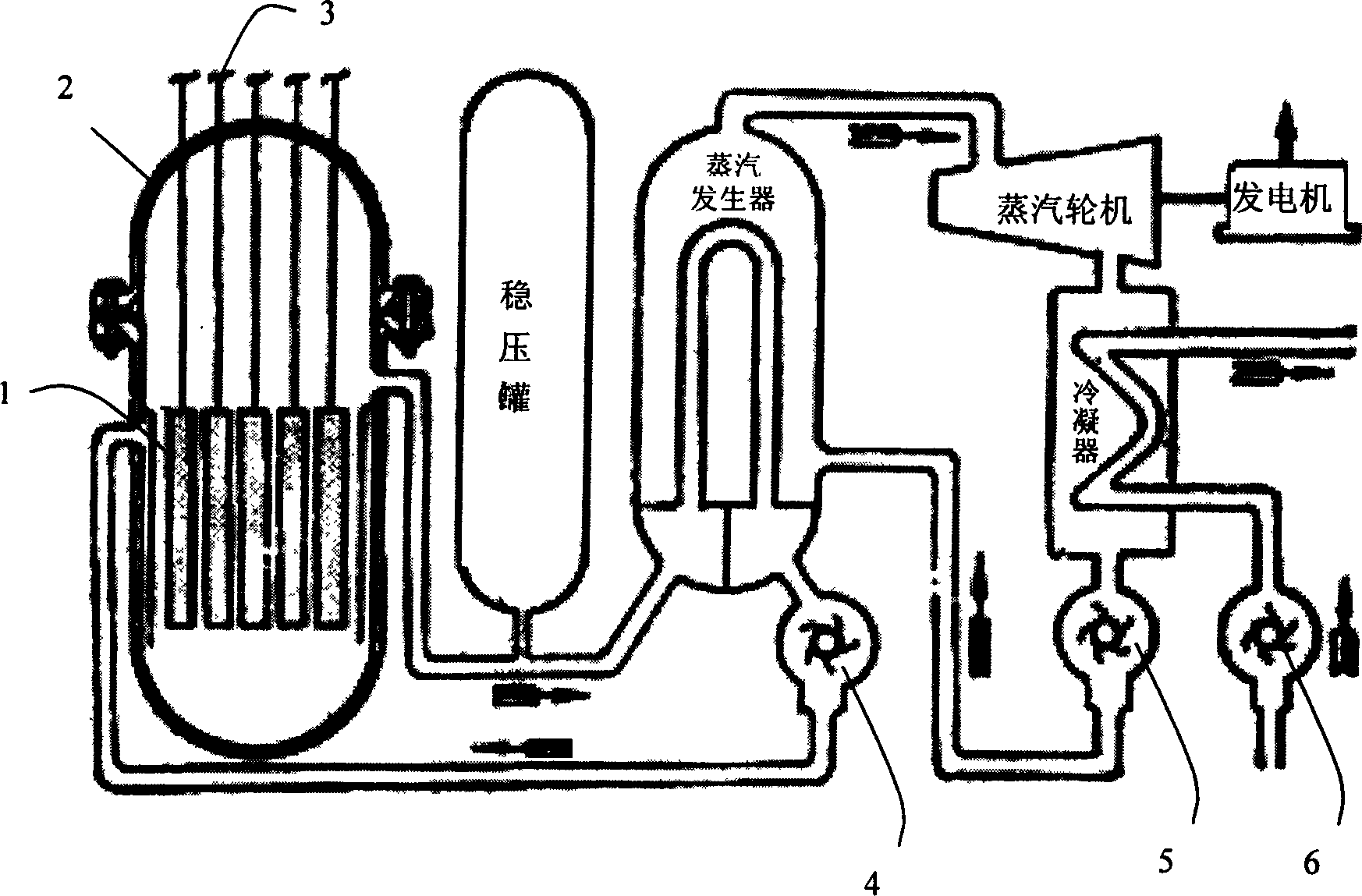

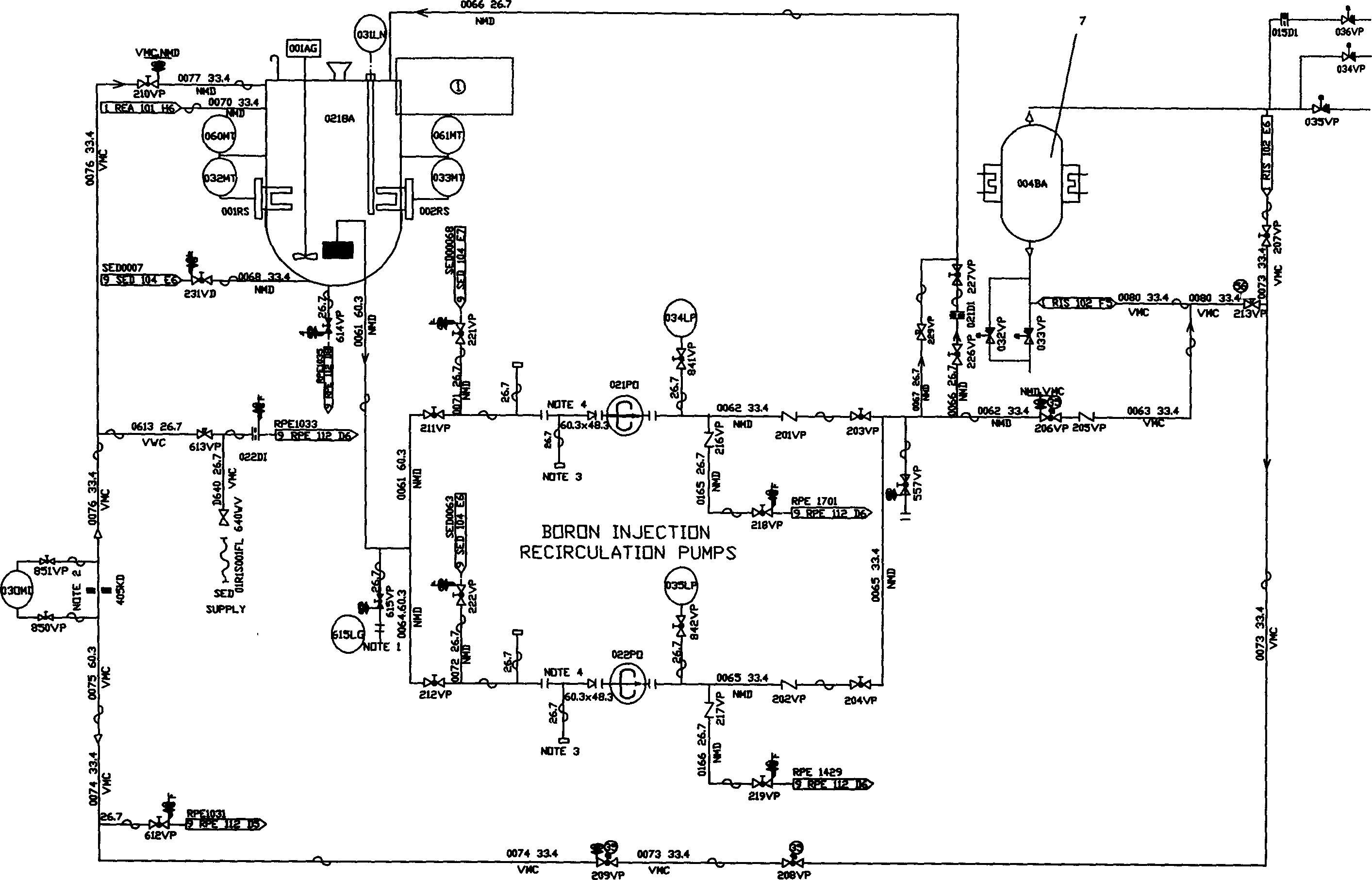

[0014] figure 2 It is a schematic diagram of the safety injection system and the concentrated boron water tank in the present invention. The safety injection system is one of the most important safety systems in nuclear power plants, and it is a system used to inject boron water into the reactor. The concentrated boron water tank 7 is located on the pipeline connecting the safety injection system to the primary circuit of the reactor, marked with 004BA in the figure. After the safety injection system is started, boron water with a certain concentration is first injected into the reactor to ensure the safety of the reactor in case of an accident.

[0015] The invention provides a method for solving the problems caused by the previous 21000ppm boron concentrated boron water tank. That is to say, reducing the boron concentration in the concentrated boron water tank to 7000-9000ppm can fundamentally solve the above problems. Replacing the 21000ppm boron water in the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com