Semiconductor device and its manufacturing method

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting component performance, short channel effect, electrical breakdown, etc., to improve electrical breakdown effect, suppress The effect of spreading out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

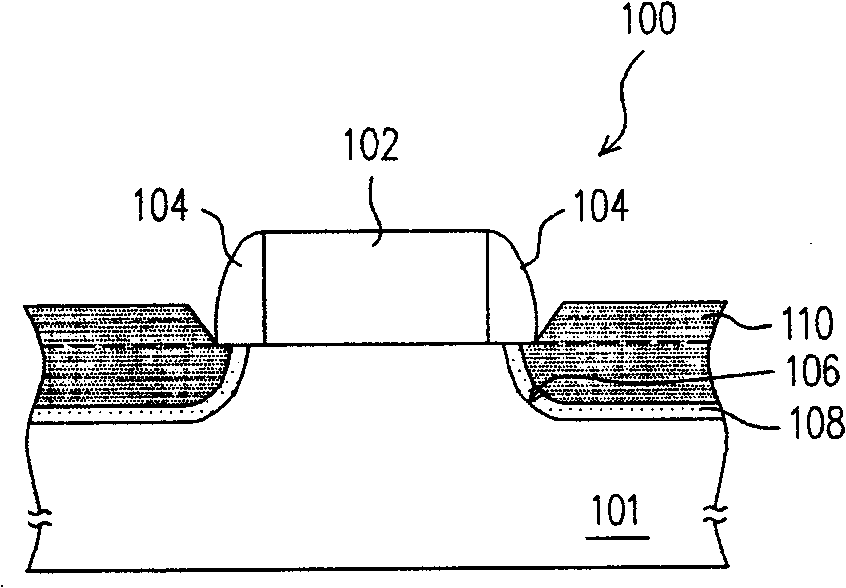

[0029] figure 1 It is a schematic cross-sectional view of a semiconductor device according to an embodiment of the present invention.

[0030] Please refer to figure 1 The semiconductor device 100 of the present invention includes a substrate 101 , a gate structure 102 , a spacer 104 , a first polysilicon germanium layer 108 doped with boron, and a second polysilicon germanium layer 110 . As mentioned above, the substrate 101 is, for example, a silicon substrate or other suitable semiconductor substrate, and has two openings 106 in the substrate 101 . The gate structure 102 is disposed on the substrate 101 between the openings 106, and the gate structure 102 is, for example, composed of a gate dielectric layer (not shown) and a gate conductor layer (not shown), and its material It is well known to those skilled in the art, so details will not be repeated here. In addition, the spacer 104 is disposed on the sidewall of the gate structure 102 and located above the partial ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com