High-entropy alloy oxide coating and preparation method thereof

A technology of oxide coating and high-entropy alloy, which is applied in the direction of metal material coating process, coating, electrochemical generator, etc., to achieve the effect of solving easy peeling, improving high temperature resistance and good adhesion

Pending Publication Date: 2022-06-10

JIANGSU UNIV OF SCI & TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Each vacancy in the crystal in the high-entropy alloy is also related to the enthalpy of mixing and the entropy of mixing. The competition between the enthalpy of mixing and the entropy of mixing produces a certain equilibrium vacancy concentration in the alloy. During the diffusion process, the vacancies in the total solute matrix In fact, surrounded and competed by different element atoms, the vacancies or atoms are migrated by the wave diffusion path, the diffusion speed is slower, and the activation energy is higher, so the diffusion phase transition is slower in high-entropy alloys

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

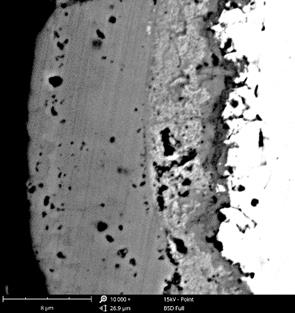

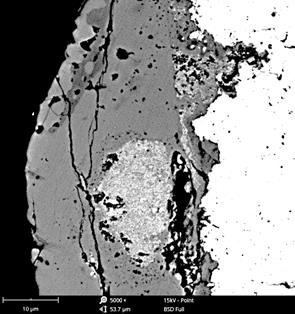

The invention discloses a high-entropy alloy oxide and a preparation method thereof, alloy elements are Cu, Mn, Co, Fe and Ni, and a high-entropy alloy oxide coating is divided into three layers, namely a (Mn, Cu) 3O4 spinel layer, a Fe oxide layer and a NiCo oxide layer in sequence from outside to inside; the preparation method of the high-entropy alloy oxide comprises the following steps: mechanically ball-milling and mixing pure metal powder, carrying out plasma spraying on a CuMnCoFeNi high-entropy alloy coating, controlling the thickness of the coating to be 15-30m, and carrying out high-temperature and high-oxygen-pressure thermal growth to form a composite conductive oxide coating. The high-entropy alloy oxide coating prepared through the method is beneficial for inhibiting external diffusion of the Cr element in a ferritic stainless steel matrix, and the high-temperature oxidation resistance of a metal connector is improved; the high-entropy alloy oxide coating with high-concentration CuMnCo elements is applied to the surface of the ferritic stainless steel, so that the coating composite connector has high electron conductivity and low ion conductivity, and the high-temperature application performance of the fuel cell metal connector is improved.

Description

technical field [0001] The invention belongs to the technical field of high-temperature protective coatings for metal connectors on the cathode side of fuel cells, and in particular relates to a high-entropy alloy oxide coating material and a preparation method thereof. Background technique [0002] With the in-depth exploration and continuous improvement of solid oxide fuel cells, in the case of reducing the thickness of the electrolyte without compromising the effectiveness of its diffusion barrier, compared with the conductive ceramic connecting materials required at higher temperatures (1000 °C), Metal connection materials have the advantages of high thermal and electrical conductivity, low cost, and easy processing. Metal connectors can be divided into Cr, Ni, and Fe-based alloys. Compared with the first two alloys, Fe-based alloys have the advantages of higher ductility, good machinability, thermal expansion coefficient matching, and low cost. Insufficient oxidation r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C4/08C23C4/134C23C4/18C22C30/02C23C8/10H01M8/0297

CPCC23C4/08C23C4/134C23C4/18C22C30/02C23C8/10H01M8/0297Y02E60/50

Inventor 邵勇黄明瑞郭平义潘家琛王冬朋崔文宁王宇鑫汤雁冰何震郭云霞殷童

Owner JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com