Method for determining boron content in rubber

A boron content, rubber technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problem that boron content has not been reported publicly, and achieve the effect of wide measurement range, good selectivity, high accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

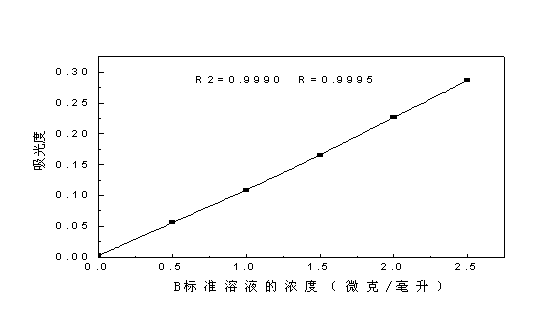

Image

Examples

Embodiment 1

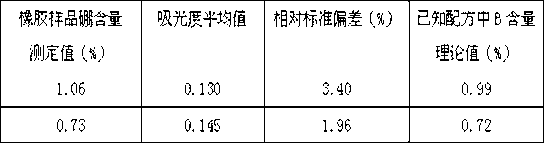

[0035] The boron content of the known formula rubber sample was measured, and the measured value of the boron content was compared with the theoretical value added. The analysis results are as follows:

[0036]

Embodiment 2

[0038] Carry out standard addition recovery test to blank solution, test result is shown in the following table:

[0039] Added value (μg / mL) Measured value (μg / mL) relative standard deviation(%) Recovery rate(%) 1.000 0.998 1.95 99.8 0.500 0.516 3.90 103.0 2.000 2.025 2.46 101.2

Embodiment 3

[0041] The sample solution diluted 10 times was subjected to the standard recovery test, and the test results are shown in the following table:

[0042] Boron concentration in unspiked sample solution (μg / mL) Add B standard solution concentration (μg / mL) B concentration measured after adding standard (μg / mL) relative standard deviation(%) Recovery rate(%) 0.741 1.000 1.751 1.81 101.0 1.230 1.000 2.205 2.67 97.5 1.029 1.000 2.020 3.90 99.1

[0043] As can be seen from the test results in Examples 1, 2, and 3, the method has good accuracy and precision.

[0044] As can be seen from the above, the present invention has established a standard test method that adopts graphite furnace atomic absorption spectrometry to measure boron content in rubber. The method has wide measuring range, clear operation steps, easy to master, and high accuracy and precision of analysis results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com