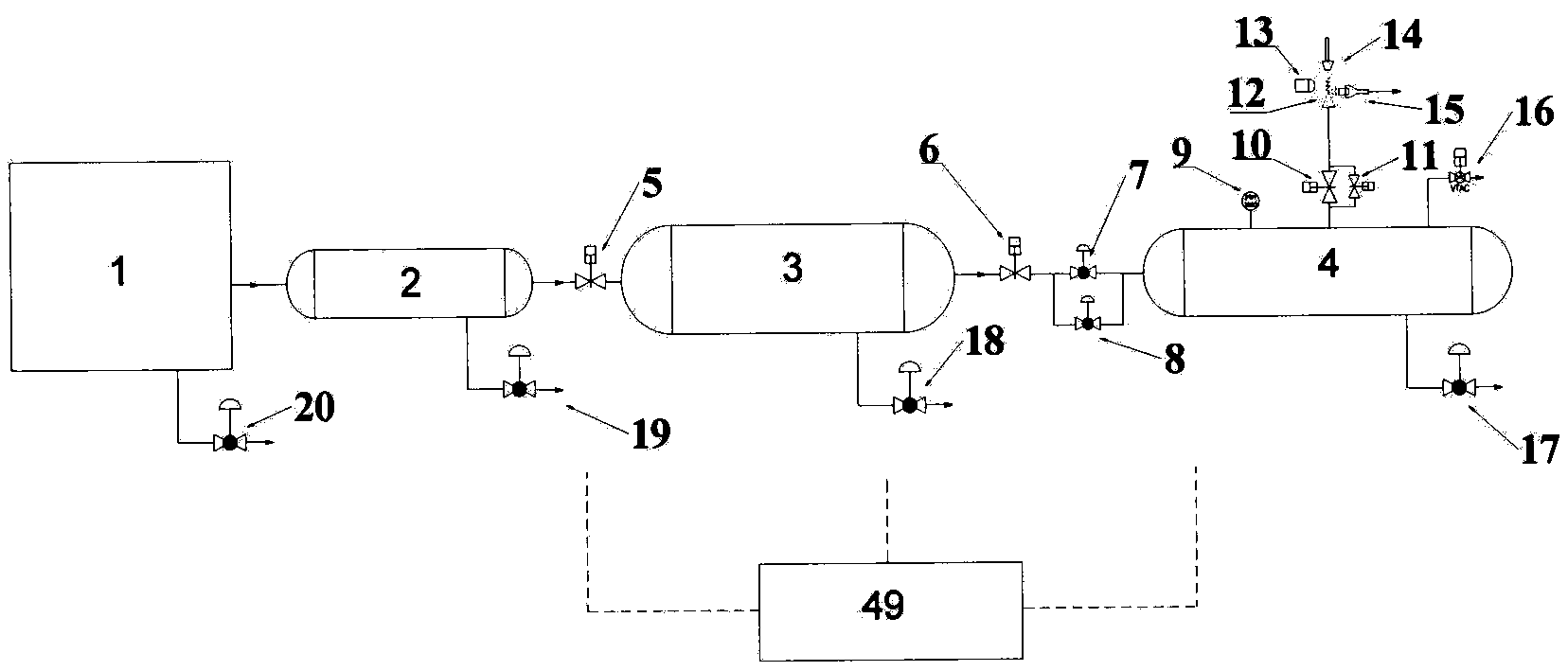

Test device and test method for testing heat-state mechanical performance of safety valve

A test device and mechanical performance technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as laser interference, inability to cooperate with safety valves, inability to accurately measure discharge pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

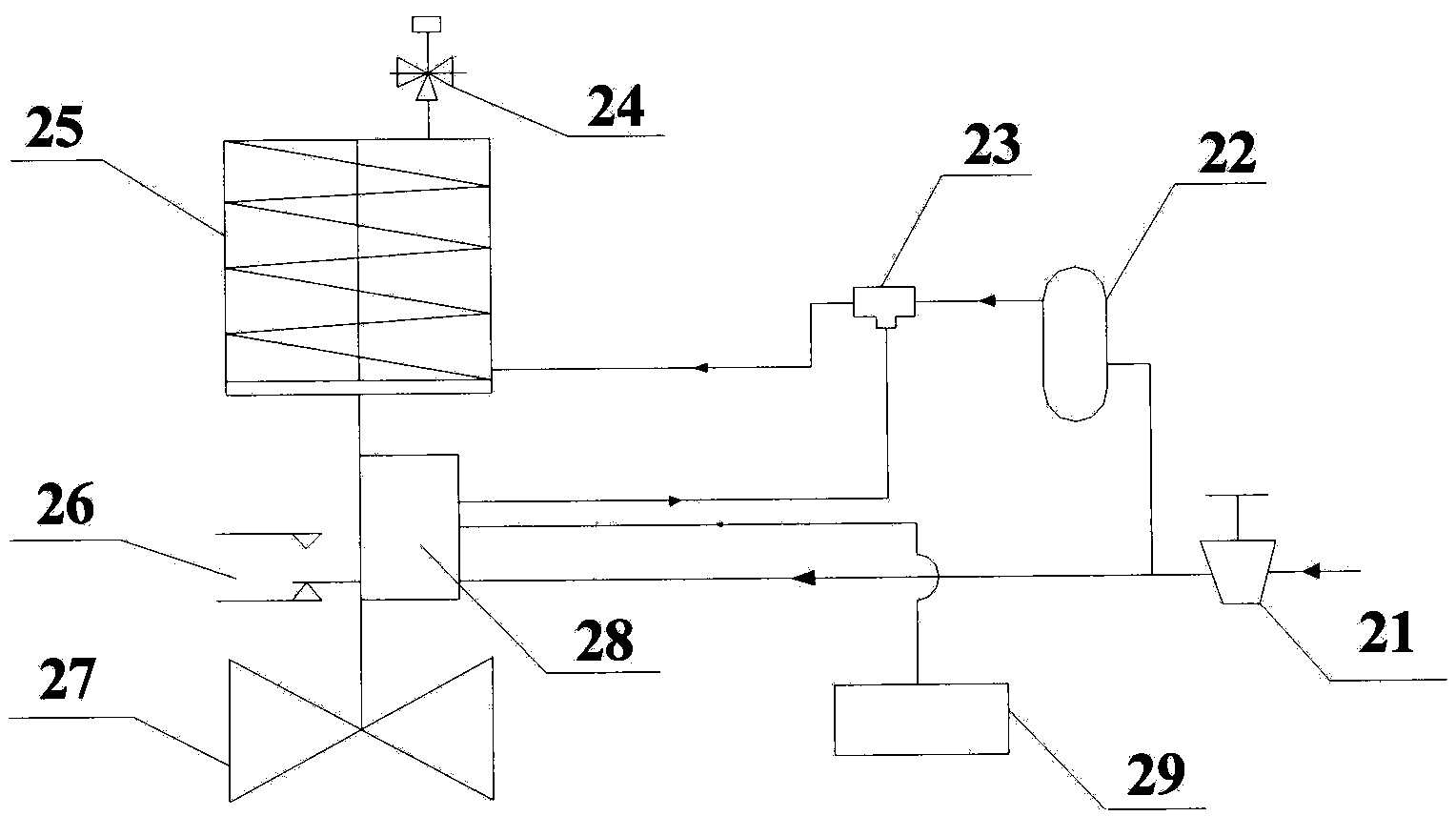

Method used

Image

Examples

Embodiment

[0076] Tested valve: nuclear power main steam safety valve, set pressure 8.7MPag, nominal diameter 200mm, displacement 486ton / h.

[0077] (1) Start the boiler, discharge steam to the accumulator and test system for preheating.

[0078] (2) Combine the boiler start-up process with the accumulator / test system warm-up process to save time. Process temperature control The temperature of the inner and outer walls of the container does not exceed 50°C, and the pneumatic control valve at the bottom of the container is opened every half an hour to discharge condensed water.

[0079] (3) When the pressure of the accumulator and the test vessel reaches 6.96Mpag, close the small-diameter and large-diameter regulating valves on the inlet pipe of the test vessel, and stop boosting the pressure of the test vessel. After the boiler is stable, the control pressure is 19.3Mpag.

[0080] (4) Calibrate the initial value of the laser testing device and the electromagnetic measuring device for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com