This transition is driven by both the increasing

impact of the RC interconnect

delay on device speed and by the

electromigration (i.e., the self-

diffusion of

metal along interconnects, thereby affecting reliability) limitations of aluminum based conductors for sub 0.25 μm device generations.

Two major challenges exist for

copper wiring technology: the barrier and seed

layers.

This leads to electrical leakage between

metal wires and poor device performance.

The

dielectric material can be a low

dielectric constant i.e., low-k material (used to reduce inter- and intra-line

capacitance and cross-talk) which typically suffers from poorer adhesion characteristics and lower

thermal stability than traditional

oxide insulators.

A discontinuity in the seed layer will lead to sidewall voiding, while gross overhang will lead to pinch-off and the formation of top voids.

However, as device geometries have decreased, the step coverage limitations of PVD have increasingly become an issue since it is inherently a line-of-

sight process.

As a result, PVD is unable to deposit thin continuous films of adequate thickness to coat the sides and bottoms of high

aspect ratio trenches and vias.

Moreover, medium / high-density

plasma and ionized PVD sources developed to address the more aggressive device structures are still not adequate and are now of such complexity that cost and reliability have become serious concerns.

Unfortunately, CVD requires comparatively high deposition temperatures, suffers from high

impurity concentrations which

impact film integrity, and have higher cost-of-ownership due to long

nucleation times and poor precursor utilization efficiency.

This generally leads to high film resistivities (up to several orders of magnitude higher than PVD), and other degradation in film performance.

These deposition, temperatures and

impurity concentrations make CVD Ta and TaN unusable for

IC manufacturing, in particular for copper metallization and low-k integration.

Although the

deposition temperature has been reduced by increased fragmentation (and hence increased reactivity) of the precursor gases in the

gas phase via a

plasma, the same fragmentation leads to the deposition of unwanted impurities.

Gas-phase fragmentation of the precursor into both desired and undesired species inherently limits the

efficacy of this approach.

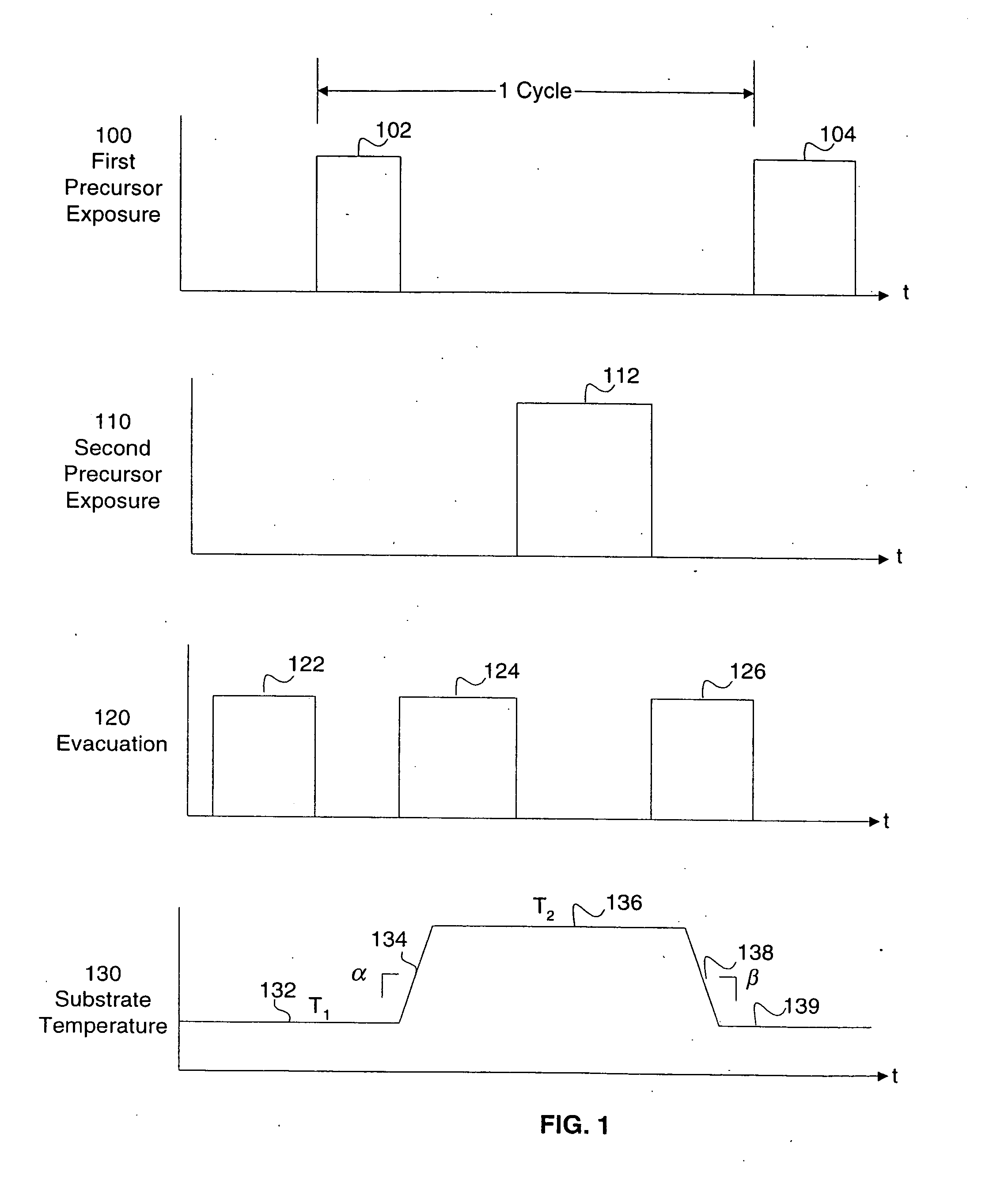

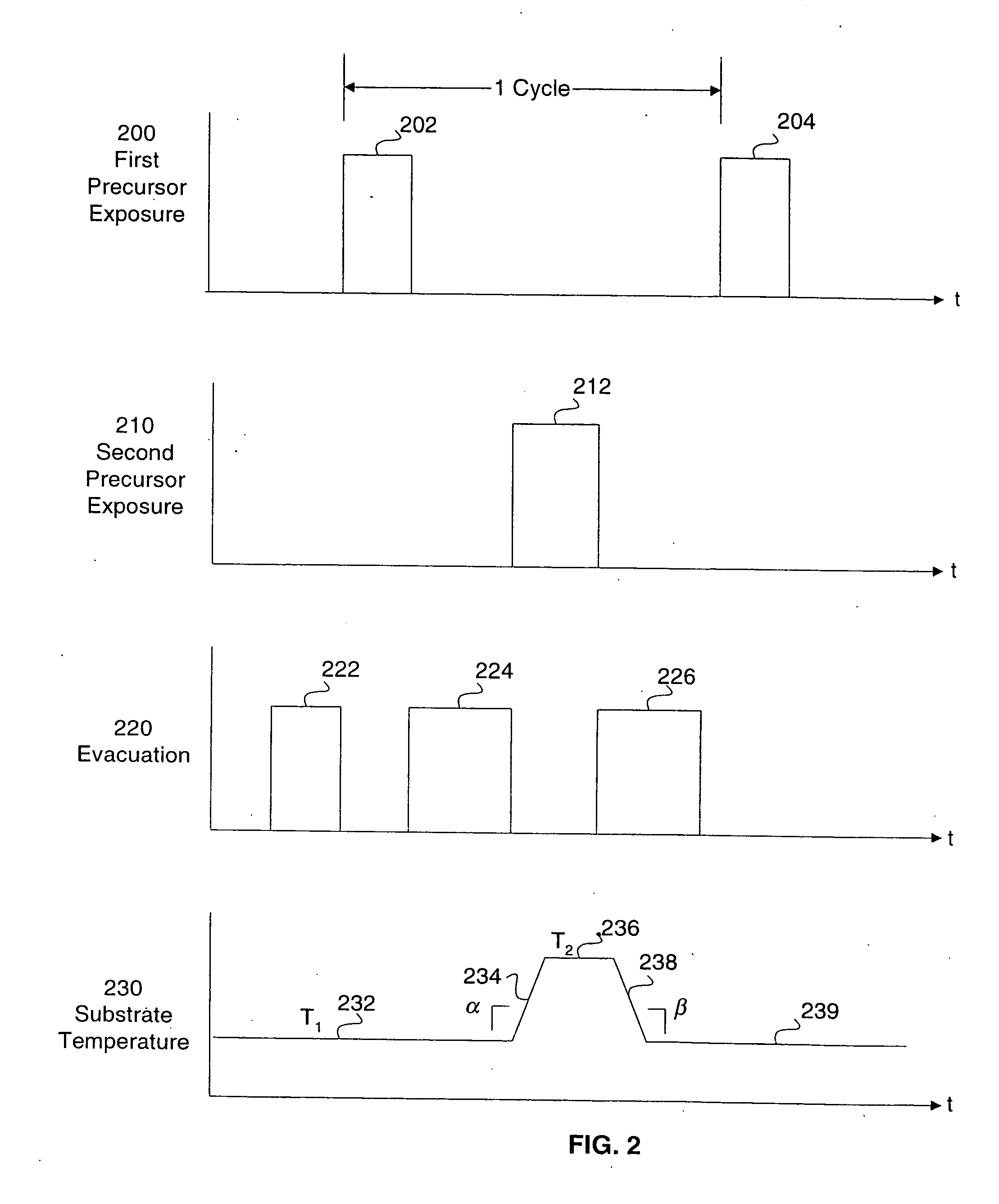

In practice, ALD is complicated by the painstaking selection of a process temperature

setpoint wherein both: 1) at least one of the reactants sufficiently adsorbs to a

monolayer and 2) the surface deposition reaction can occur with adequate growth rate and film purity.

If the temperature is too low, the deposition reaction may be incomplete (i.e., very slow), not occur at all, or lead to poor film quality (e.g.,

high resistivity and / or high

impurity content).

Since the ALD process is entirely thermal, selection of available precursors (i.e., reactants) that fit the temperature window becomes difficult and sometimes unattainable.

Due to the above-mentioned temperature-related problems, ALD has been typically limited to the deposition of semiconductors and insulators as opposed to metals.

Chlorine is a corrosive, can

attack copper, and lead to reliability concerns.

Unfortunately, due to the temperature conflicts that plague the ALD method and lack of kinetically favorable second reactant, serious compromises in process performance result.

Using such a technique, Ta ALD films have been deposited at 0.16 to 0.5 Å / cycle at 25° C., and up to 1.67 Å / cycle at 250° C. to 450° C. Although REALD results in a lower operating substrate temperature than all the aforementioned techniques, the process still suffers from several significant drawbacks.

However, such temperatures are still too high for some films of significant interest in

IC manufacturing such as

polymer-based low-k dielectrics that are stable up to temperatures of only 200° C. or less.

Moreover, a porous or under-dense film has lower

chemical stability and can react undesirably with overlying or underlying films, or with

exposure to gases commonly used in IC manufacturing processes.

Another limitation of REALD is that the radical generation and delivery is inefficient and undesirable.

RF (such as 13.56 MHz)

plasma generation of radicals used as the second reactant such as atomic H is not as efficient as

microwave plasma due to the enhanced efficiency of

microwave energy transfer to electrons used to sustain and dissociate reactants introduced in the plasma.

Furthermore, having a downstream configuration whereby the radical generating plasma is contained in a separate vessel located remotely from the main chamber where the substrate is situated and using a small aperture to introduce the radicals from the

remote plasma vessel to the main chamber body significantly decreases the efficiency of transport of the second radical reactant.

In the case of atomic H, these recombination pathways will lead to the formation of diatomic H2, a far less effective

reducing agent.

Finally, ALD (or any derivative such as REALD) is fundamentally slow since it relies on a sequential process whereby each deposition cycle is comprised of at least two separate reactant flow and evacuation steps which can occur on the order of minutes with conventional valve and chamber technology.

Login to View More

Login to View More