Method for estimating reverse twisting process of fan blade of gas turbine

A technology of fan blades and gas turbines, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as imperfect anti-twist design methods of gas turbine fan blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

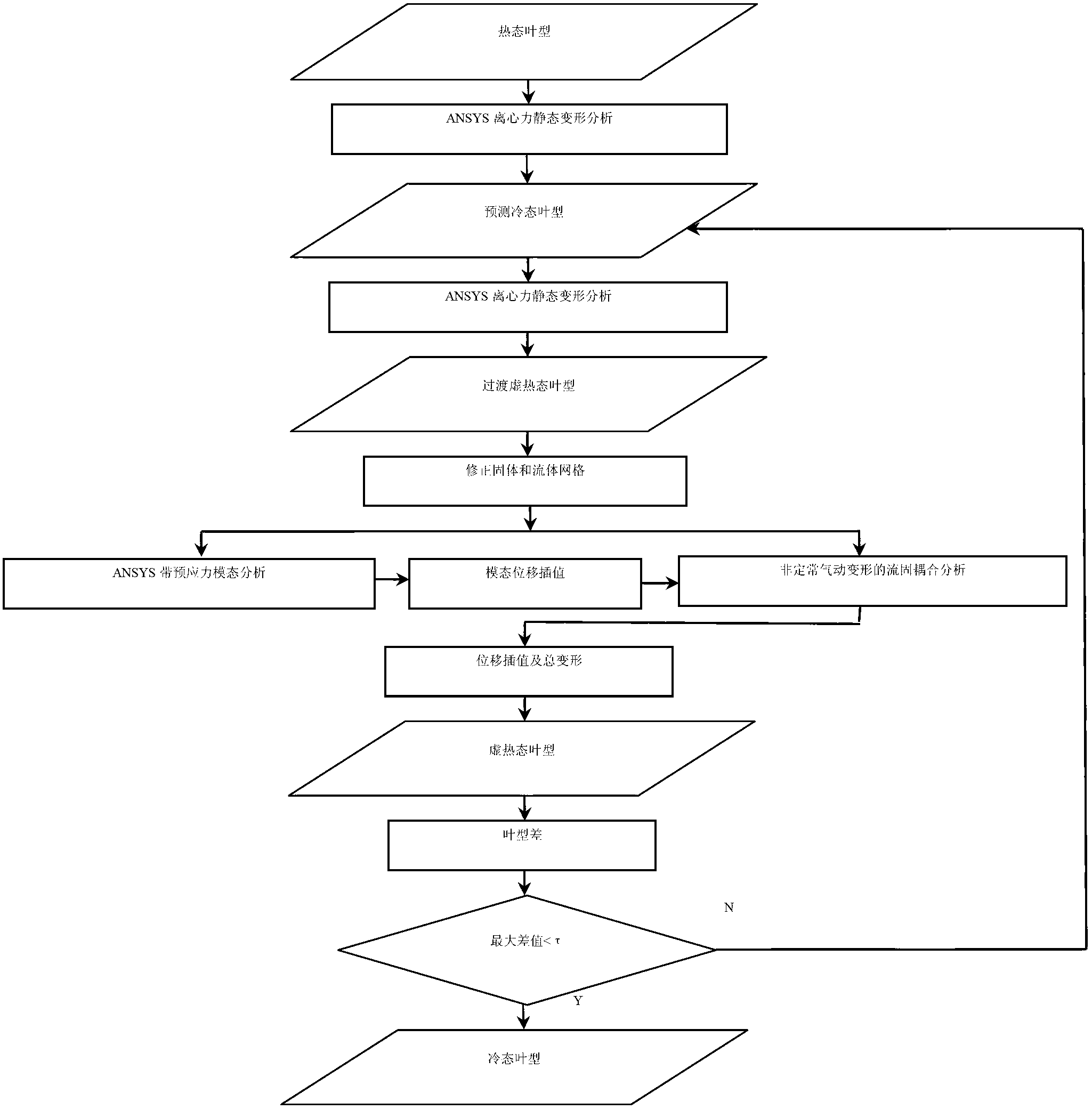

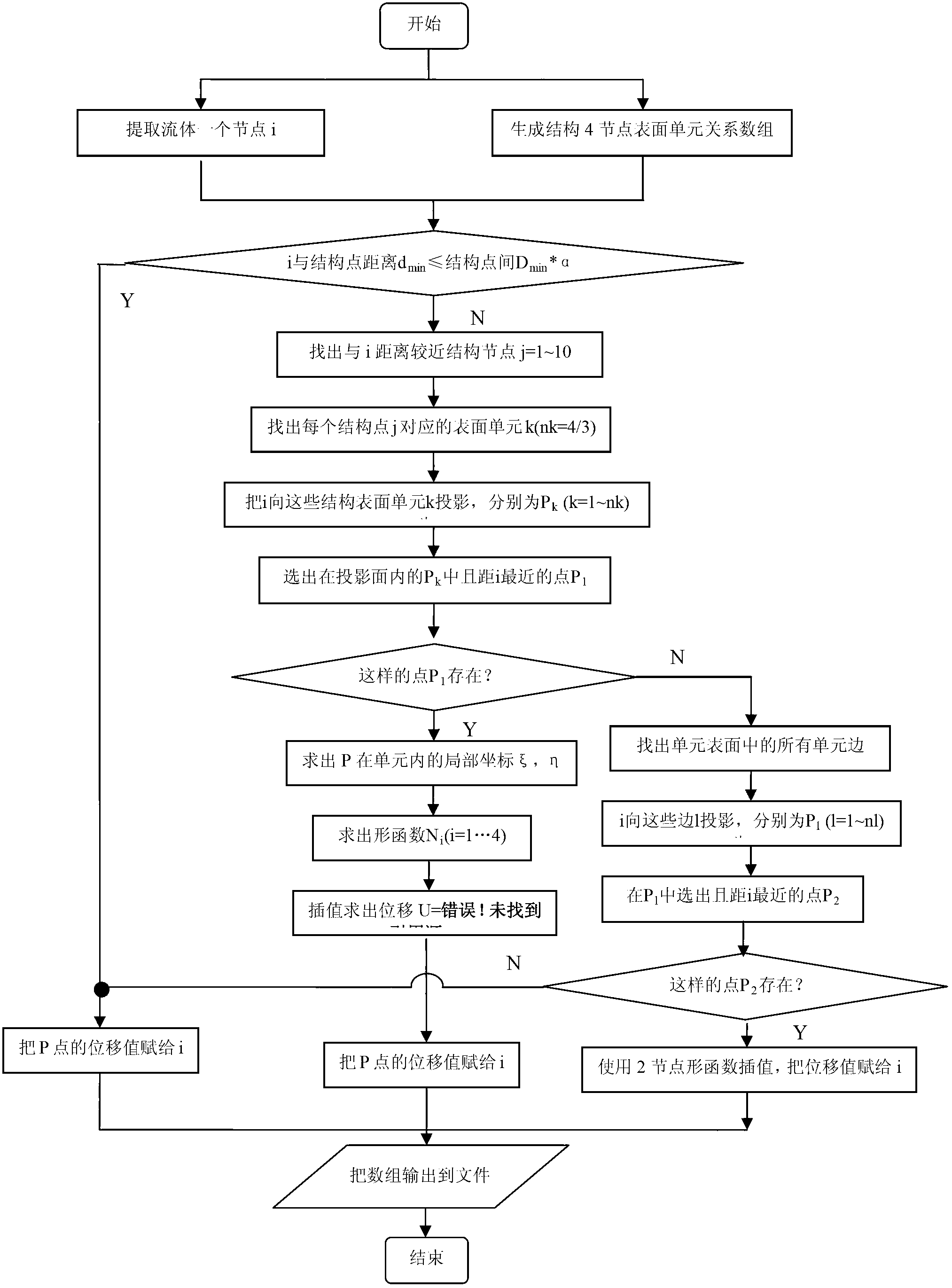

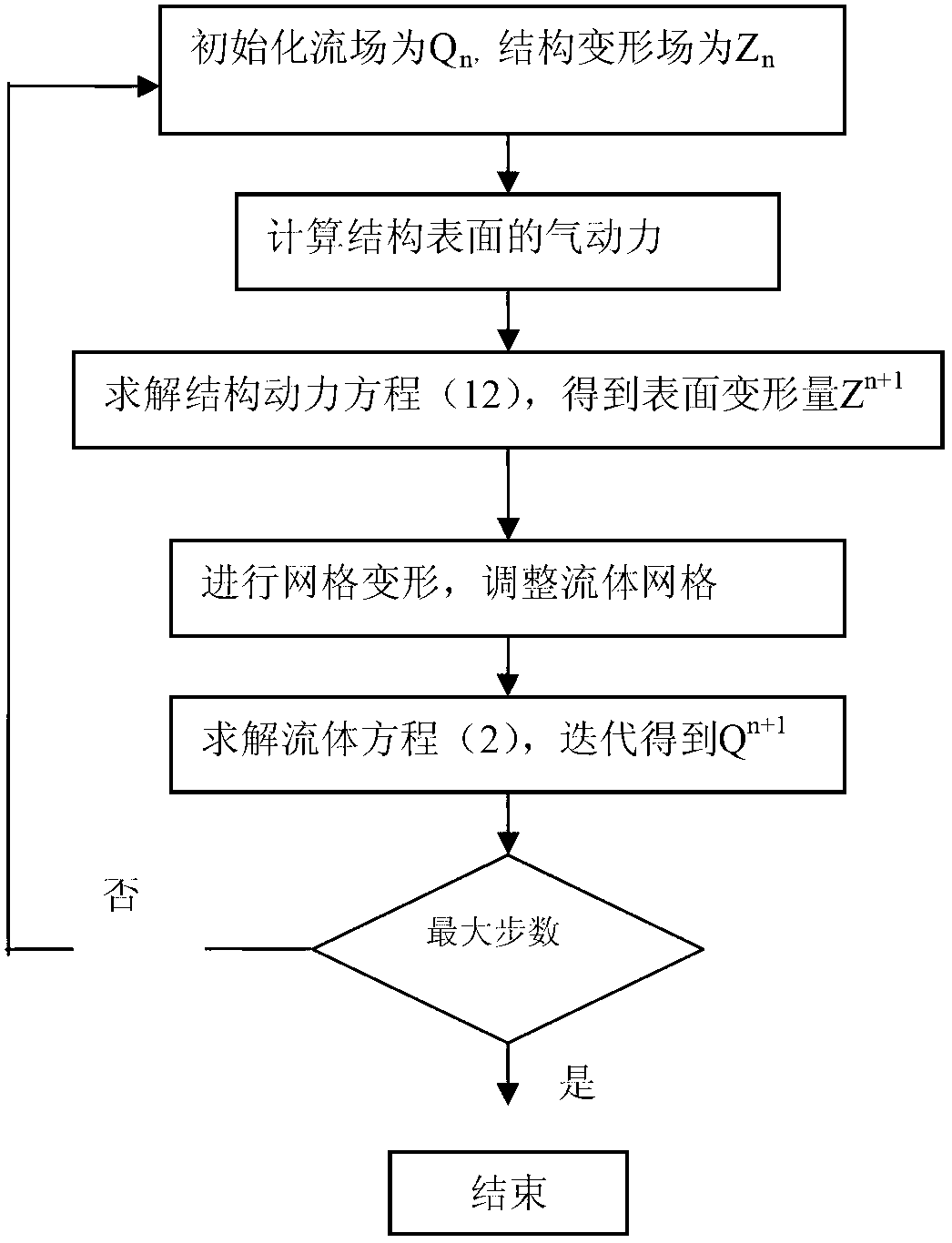

[0041] Such as Figure 1~3 As shown, a method for estimating the anti-twist process of a gas turbine fan blade in this embodiment is realized by the following steps:

[0042] Step 1: Take the geometrical data of the blade as the original thermal blade profile and the blade material as the material selected during the design to obtain the elastic constant and Poisson's ratio performance parameters. Such as titanium alloy: the elastic constant is EX=1.12E11Pa, Poisson's ratio is 0.3, and the density is 4440kg / m3. Take the aerodynamic condition of the design point as the working point;

[0043] Step 2: According to the geometric value of the thermal blade under the original design condition, use the three-dimensional solid configuration software UG to construct the geometric model of the fan blade;

[0044] Step 3: Import the geometric model of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com