Full-automatic discharging method and equipment for steel strand anchor cable

A steel wire, fully automatic technology, applied in the field of the steel wire anchor cable automatic cutting method and equipment field, can solve the problems of polluting the environment, low efficiency and the like, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

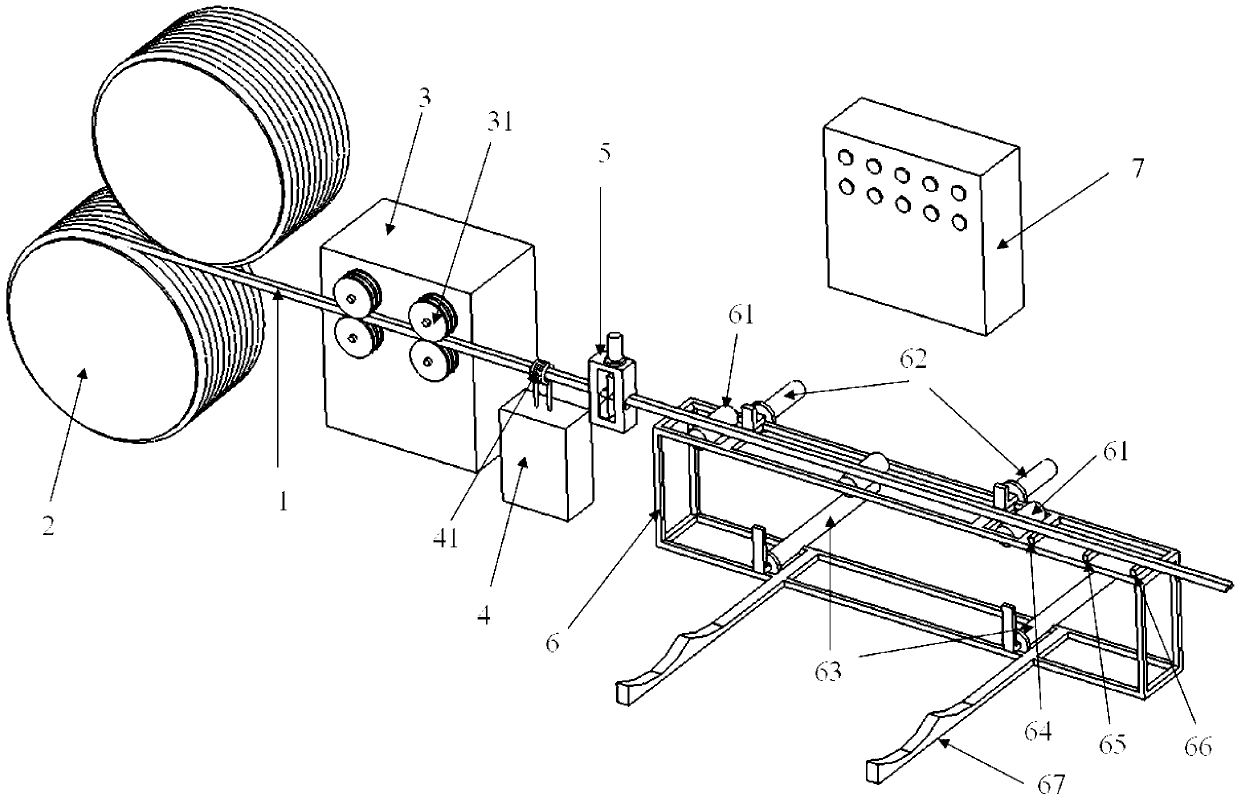

[0022] like figure 1 Shown, the concrete steps of a kind of fully automatic blanking method of steel strand anchor cable are:

[0023] ① Place the two coils of steel strand 1 on the two steel strand coil racks 2 respectively, pull out the ends of the two steel strands, open the electrical control cabinet 7, and adopt the manual operation mode: start the traction machine 3, the traction machine 3 The pinch roller 31 rotates, drives two steel strands 1 to pass through the eddy current heater 4 and the hydraulic shearer 5 in sequence, and enters the running track on the unloading frame 6, stops the tractor 3, and completes the steel strand on-line process;

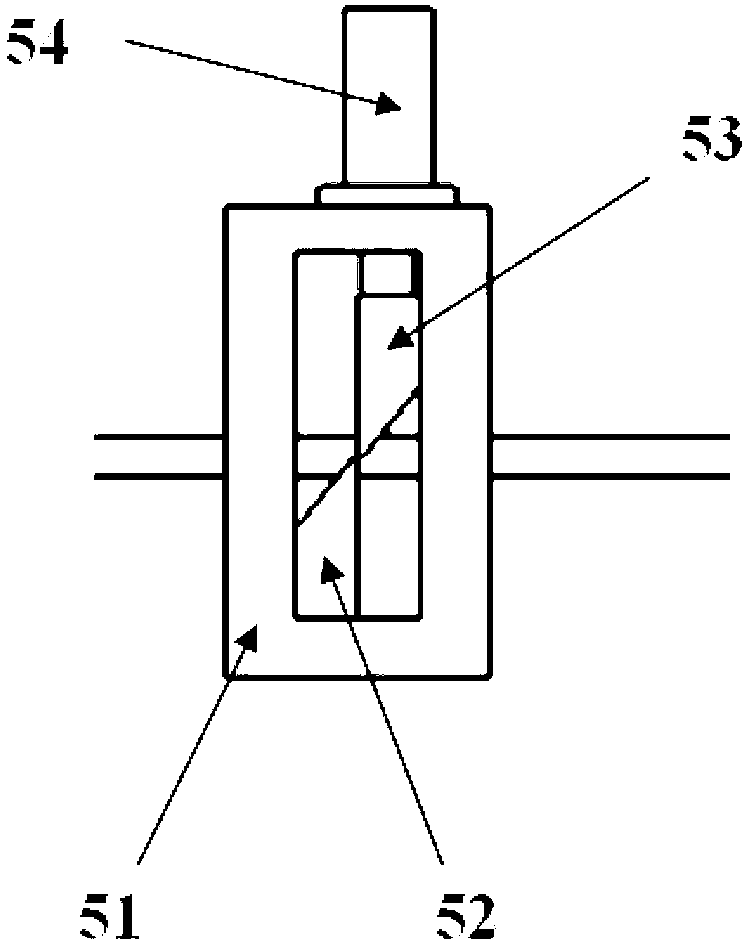

[0024] ② Turn on the electrical control cabinet 7 and adopt the automatic operation mode: start the tractor 3, the pinch roller 31 of the tractor 3 and the conveying roller 61 on the unloading frame 6 rotate, and start to convey the steel strand until the front end of the steel strand 1 reaches The position of the first dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com