Middle peeling device and peeling method for wire materials

A wire rod and intermediate part technology, applied in the field of wire rod intermediate peeling device, can solve the problem of unstable peeling length and achieve the effect of improving stability and avoiding rubber rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

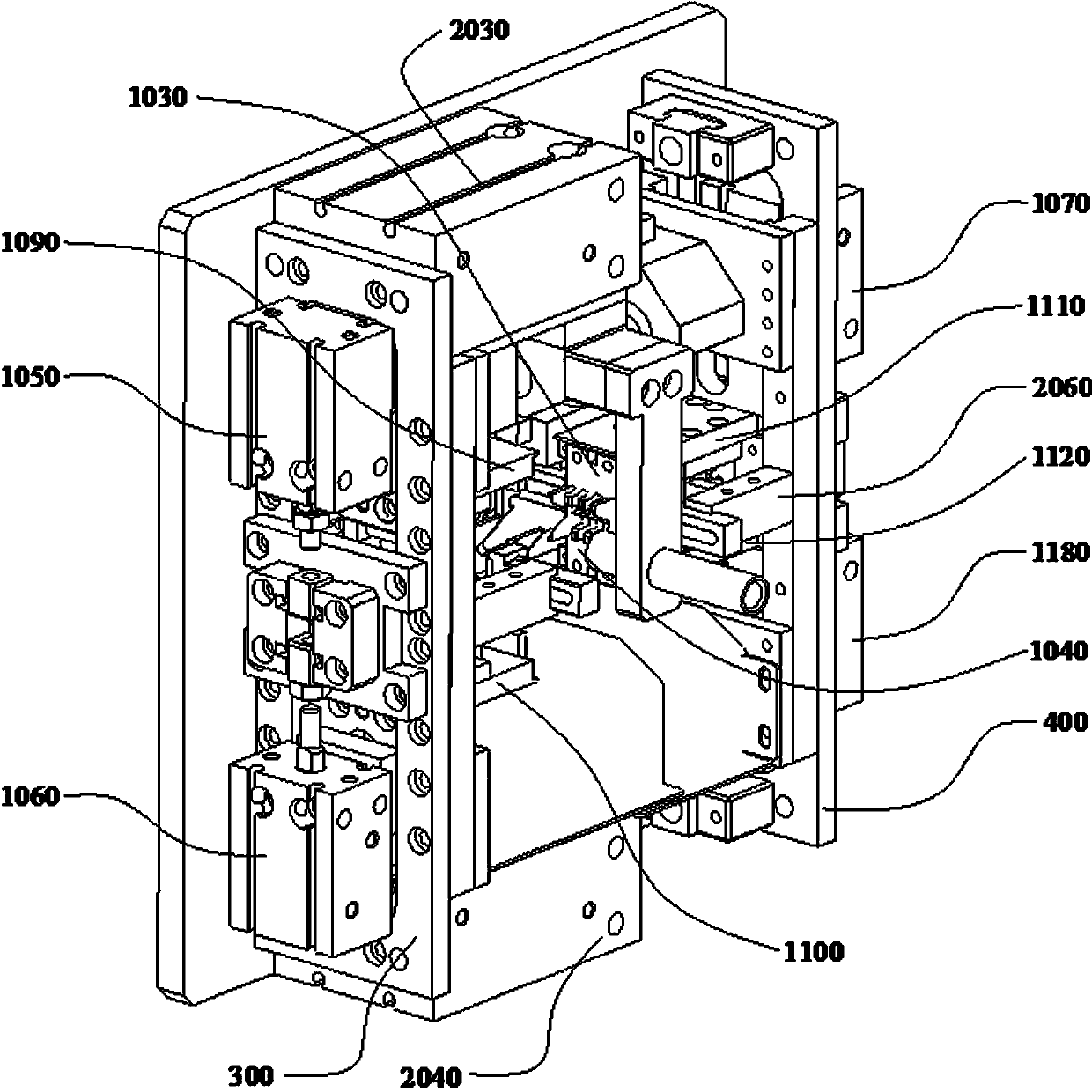

[0023] refer to Figure 1-Figure 6 As shown, the present invention provides an intermediate stripping device for wires, which includes an axial cutter set 100 for forming an axial incision on the rubber in the middle part of the wire, and a diameter for forming radial incisions in the rubber in the middle part of the wire. To the knife set 200, and the axial knife set 100 also strips the rubber in the middle part of the wire from the wire along the axial incision.

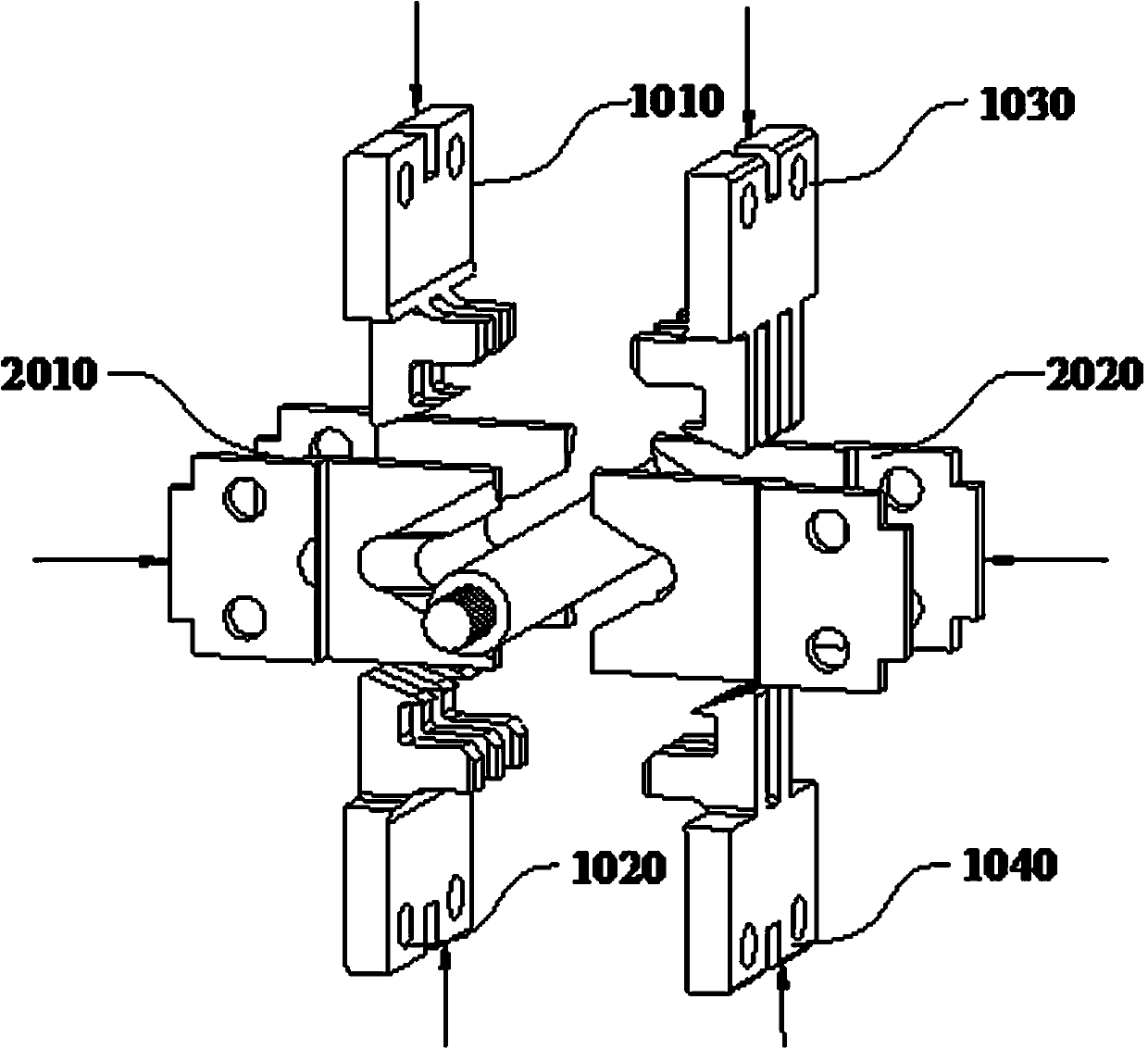

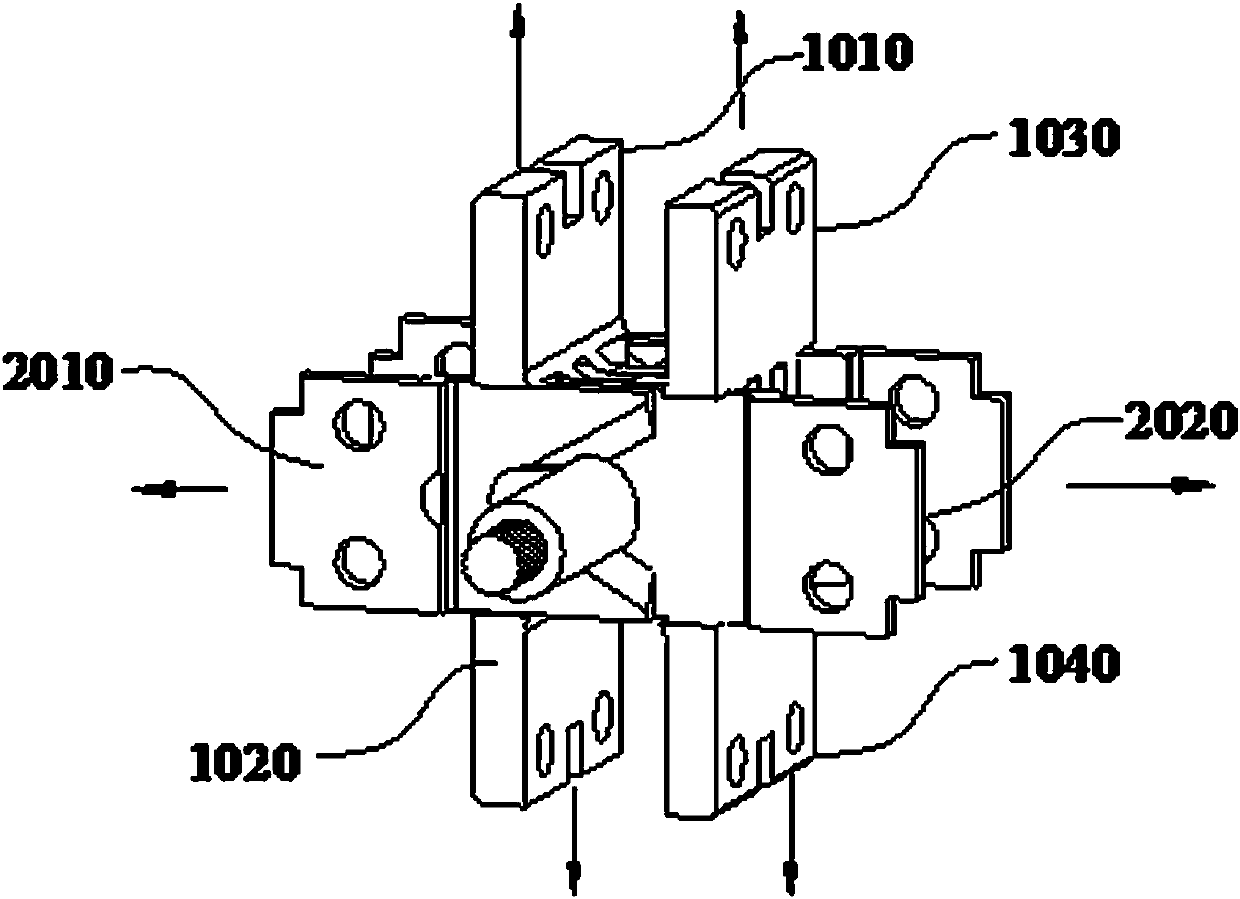

[0024] Specifically, the above-mentioned axial cutter set 100 includes vertically matched first axial multi-tooth cutters 1010 and second axial multi-toothed cutters 1020, and vertically matched third axial multi-toothed cutters 1030 and fourth axial multi-toothed cutters 1030 and fourth axial multi-toothed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com