Spark plug for use in an internal-combustion engine

A technology for internal combustion engines and spark plugs, which is applied in the field of spark plugs for internal combustion engines, can solve problems such as the impossibility of spark plug ignition stability, and achieve the effects of preventing rebound, corrosion, and deterioration of ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

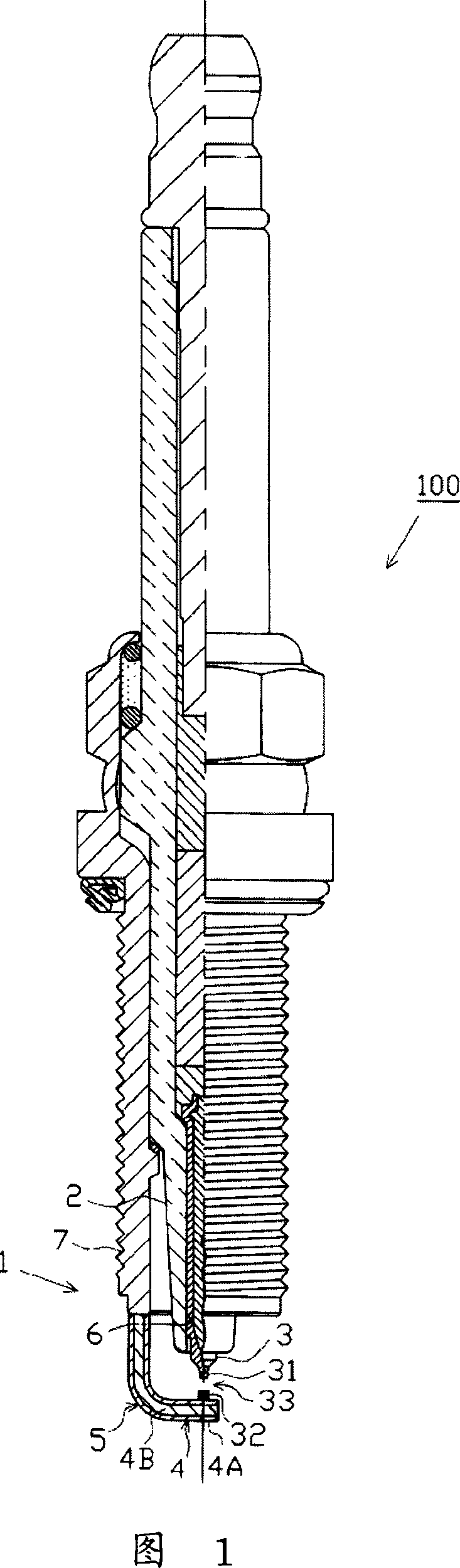

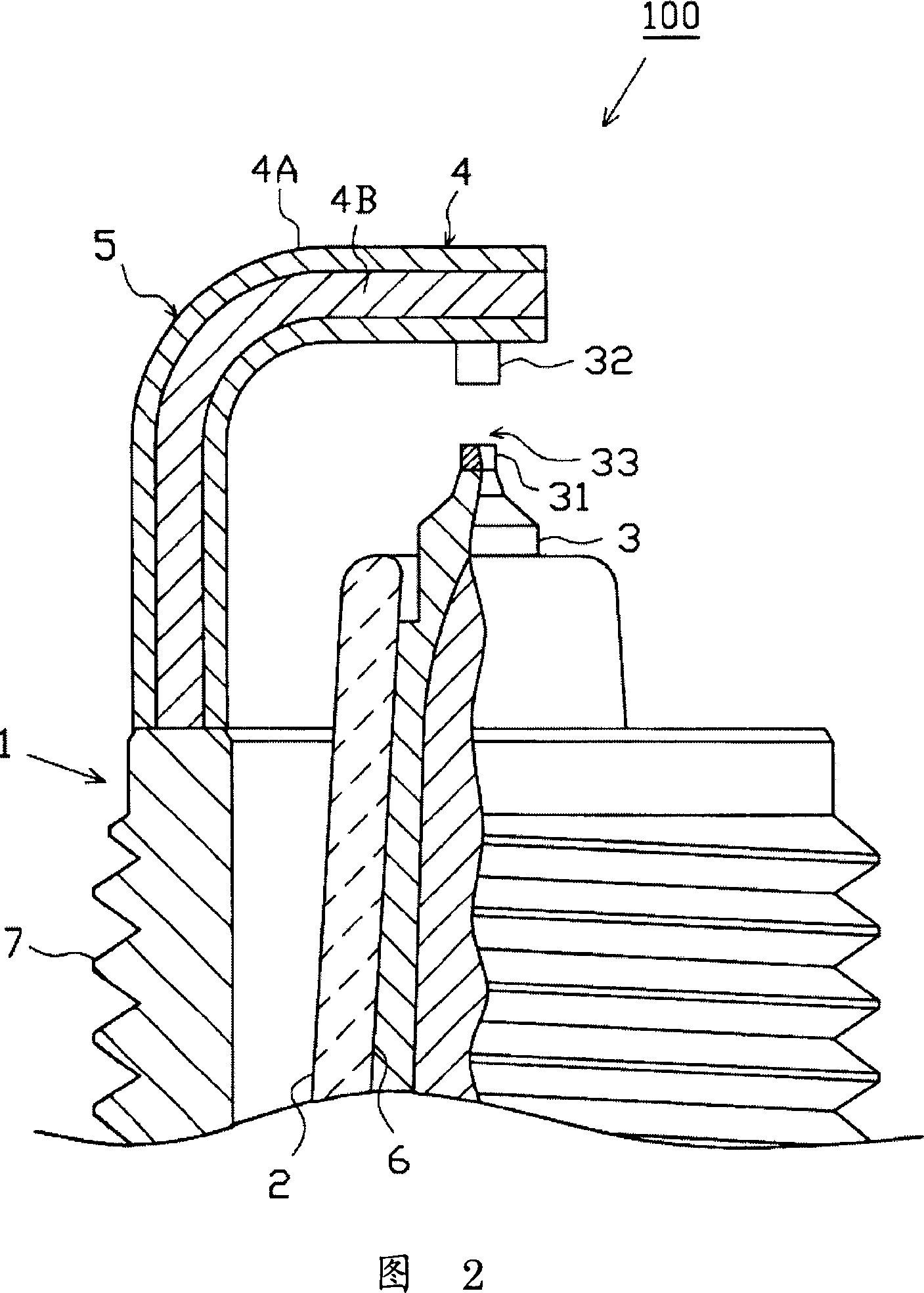

[0054] A first embodiment of the present invention will be described with reference to the drawings. FIG. 1 is a partially cutaway front view showing the entire configuration of a spark plug according to the present embodiment, and FIG. 2 is a partially cutaway front view showing main components. Hereinafter, the present invention will be described mainly with reference to FIG. 2 .

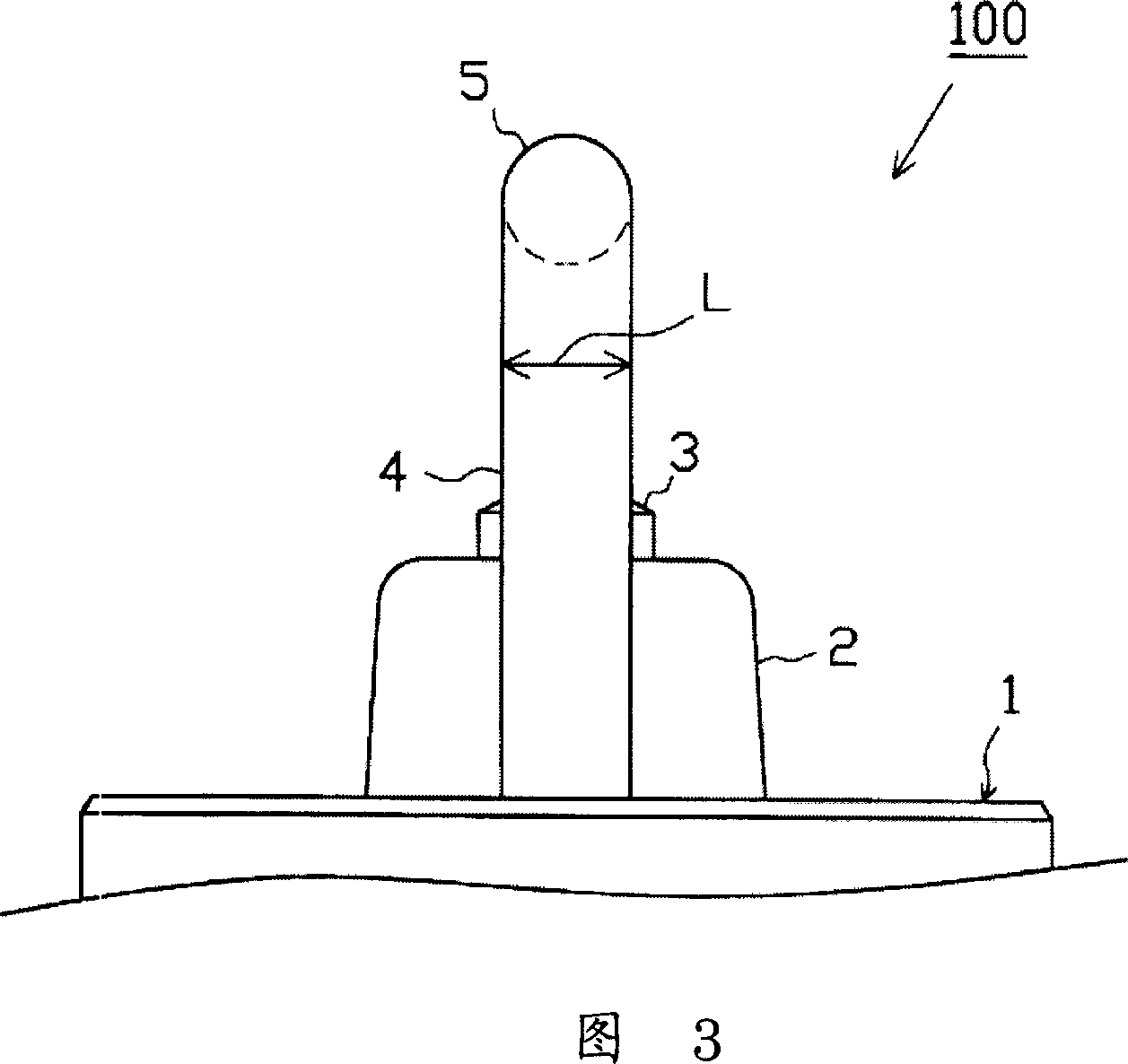

[0055] As shown in FIG. 2 and the like, the spark plug 100 according to the present embodiment is composed of a metal case 1 , an insulator 2 , a center electrode 3 and a ground electrode 4 . Although no specific reference numeral is assigned, a contact terminal electrically connected to the center electrode 3 through a resistor or a glass seal portion on the rear end side of the insulator 2 and the like are also provided. The metal case 1 has a cylindrical shape, and the insulator 2 is held in the metal case 1 by talc, packing, or the like. The front end portion of the insulator 2 protrudes fro...

no. 2 example

[0083] Next, a second embodiment of the present invention will be explained. In this embodiment, any part that is the same as that of the first embodiment is denoted by the same reference numeral, and a detailed description thereof will be omitted. Portions different from the first embodiment will be mainly explained.

[0084] The spark plug according to this embodiment is also composed of a metal case 1 , an insulator 2 , a center electrode 3 and a ground electrode 4 . In this embodiment, the constitution of the ground electrode 4 is different from that of the first embodiment.

[0085] Similar to the first embodiment, the main body of the ground electrode 4 has a two-layer structure composed of an outer layer 4A and an inner layer 4B, and the outer layer 4A in this embodiment is also composed of a nickel alloy such as Inconel 600 or the like. On the other hand, the inner layer 4B in the second embodiment is composed of high-purity nickel (for example, pure nickel: includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com