Surface strengthening ancient-Chinese-fir-imitation floor base material and manufacturing method thereof

A technology of surface strengthening and manufacturing method, applied in the direction of wood treatment, impregnating wood, manufacturing tools, etc., can solve the problems of low added value, poor dimensional stability, low production efficiency, etc., to improve dimensional stability, excellent dimensional stability, Small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

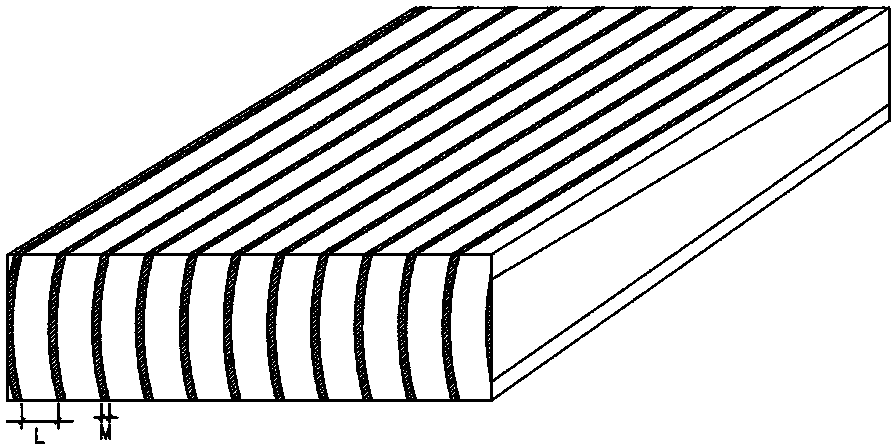

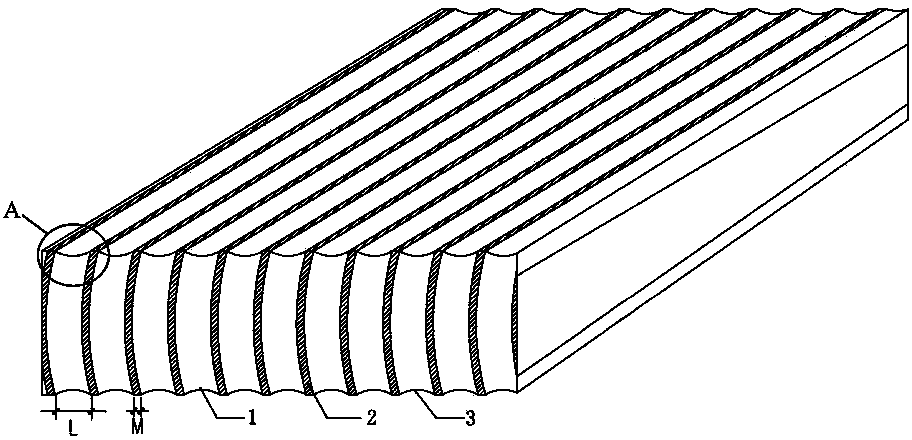

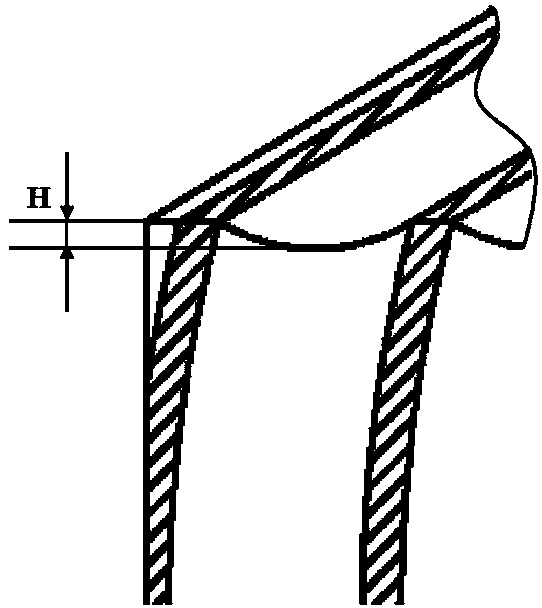

[0033] A surface-strengthened antique fir floor base material of the present invention is mainly made of fir sawn timber as a raw material. The hardness of the fir sawn timber is 16.98MPa, and the wear rate is 0.158g / 100r. The surface density is 0.8g / cm 3 (The surface layer usually refers to the range from the surface of the base material to about 2cm below the surface). The hardness of the surface reinforced antique fir floor base material is 32.27MPa, and the wear rate is 0.095g / 100r. Such as figure 2 As shown, the surface of the surface reinforced antique fir floor substrate is provided with concave-convex texture, the depth H of the groove 3 of the concave-convex texture is 1.5 mm, and the average width of the early wood 1 is 3 mm (the width L of the early wood 1 is generally between 2 and 2 mm). 5mm), the width M of latewood 2 is 0.5mm.

[0034] In this embodiment, the Chinese fir sawn timber is a quarter-sawn board, and the variation of the uneven texture on the surfa...

Embodiment 2

[0045] A surface-strengthened antique fir floor base material of the present invention is mainly made of fir sawn timber as a raw material. The hardness of the fir sawn timber is 16.98MPa, and the wear rate is 0.158g / 100r. The surface density is 0.6g / cm 3 , the hardness is 25.04MPa, and the wear amount is 0.112g / 100r. The surface of the surface reinforced antique fir floor base material is provided with concave-convex texture, the depth H of the groove 3 of the concave-convex texture is 1.5 mm, and the average width of the early wood 1 is 3 mm (the width L of the early wood 1 is generally 2 to 5 mm). The width M of the late material 2 is 0.5 mm.

[0046] In this embodiment, the Chinese fir sawn timber is a string-cut board, and the "V-shaped" pattern on the surface of the surface-strengthened antique fir floor base material is an uneven "V-shaped" pattern.

[0047] A method for manufacturing the above-mentioned surface-strengthened antique fir floor base material of the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com