Liquid crystal module and liquid crystal display device

A liquid crystal display device and liquid crystal module technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of product appearance restriction, low production efficiency, and large supply pressure of accessories, so as to save screw assembly or bonding The effect of reducing the adhesive bonding time, improving production efficiency and reducing supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

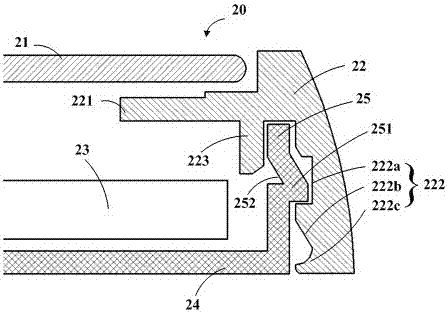

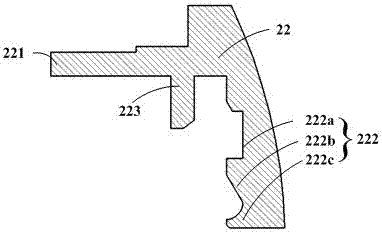

[0025] Embodiment 1 of the present application provides a liquid crystal module, such as Figure 2-Figure 6 shown. The liquid crystal module 20 includes a middle frame 22, a light guide plate 23, a back plate 24 and a first vertical plate 25, wherein the back plate 24 is located under the light guide plate 23, at the edge of the back plate 24 and toward the guide A first vertical plate 25 extends in the direction of the light plate 23; the middle frame includes a second vertical plate 222 and a third vertical plate 223 arranged on both sides of the first vertical plate 25, and the The first supporting part 221 that is vertically connected with the third vertical plate 223; the outer surface of the first vertical plate 25 includes a plurality of buckle protrusions 251 arranged at intervals, and the second vertical plate 222 is provided with the The buckle groove 222a matched with the buckle protrusion 251; the second vertical plate 222 also includes a detachment prevention gro...

Embodiment 2

[0036] Embodiment 2 of the present application further provides a liquid crystal display device, which includes a panel 21 and the liquid crystal module 20 described in Embodiment 1 above. Wherein, the liquid crystal module 20 and the panel 21 are in relative positions, and the panel 21 is located on the upper surface of the first supporting portion 221 of the liquid crystal module; the structure, function and function of the liquid crystal module 20 have been described in detail in the foregoing embodiments, and will not be described here. Let me repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com