Flame-retarding and wear-resisting fabric

A technology of wear-resistant fabrics and flame-retardant layers, applied in clothing, household appliances, applications, etc., can solve problems such as poor air permeability, user irritation, and insufficient safety, and meet safety requirements, easy to implement, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

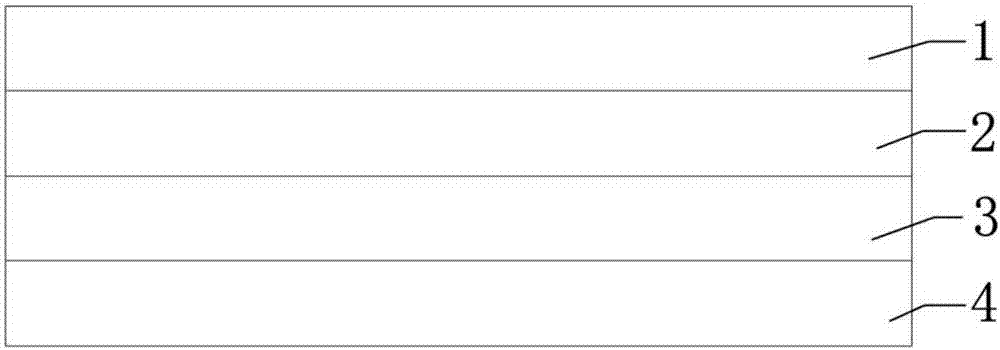

[0021] Such as figure 1 The flame-retardant and wear-resistant fabric shown is composed of a flame-retardant layer 1, a wear-resistant layer 2, a base layer 3 and a breathable layer 4 arranged from top to bottom, and the flame-retardant layer 1, wear-resistant layer 2, and base layer 3 After being bonded with the breathable layer 4 by adhesive polyurethane, it is integrally formed by heat pressing. Wherein, the base layer 3 includes the following components by weight components: 20 parts of cotton fiber, 10 parts of soybean fiber, 3 parts of polyacrylonitrile fiber, 15 parts of hemp fiber, 2 parts of sodium hydroxyethyl cellulose, 3 parts ammonium sulfate and 2 parts polyurethane. The cotton fiber and the polyacrylonitrile fiber are helically twisted as a warp fiber bundle, the soybean fiber and the hemp fiber are helically twisted as a weft fiber bundle, and the warp fiber bundle and the weft fiber bundle are sequentially interwoven into a twill weave organizational unit. ...

Embodiment 2

[0026] Such as figure 1 The flame-retardant and wear-resistant fabric shown is composed of a flame-retardant layer 1, a wear-resistant layer 2, a base layer 3 and a breathable layer 4 arranged from top to bottom, and the flame-retardant layer 1, wear-resistant layer 2, and base layer 3 After being bonded with the breathable layer 4 by adhesive polyurethane, it is integrally formed by heat pressing. Wherein, the base layer 3 includes the following components by weight components: 50 parts of cotton fiber, 40 parts of soybean fiber, 15 parts of polyacrylonitrile fiber, 25 parts of hemp fiber, 15 parts of sodium hydroxyethyl cellulose, over 8 parts of ammonium sulfate and 6 parts of polyurethane. The cotton fiber and the polyacrylonitrile fiber are helically twisted as a warp fiber bundle, the soybean fiber and the hemp fiber are helically twisted as a weft fiber bundle, and the warp fiber bundle and the weft fiber bundle are sequentially interwoven into a twill weave organizat...

Embodiment 3

[0031] Such as figure 1 The flame-retardant and wear-resistant fabric shown is composed of a flame-retardant layer 1, a wear-resistant layer 2, a base layer 3 and a breathable layer 4 arranged from top to bottom, and the flame-retardant layer 1, wear-resistant layer 2, and base layer 3 After being bonded with the breathable layer 4 by adhesive polyurethane, it is integrally formed by heat pressing. Wherein, the base layer 3 includes the following components by weight components: 30 parts of cotton fiber, 25 parts of soybean fiber, 12 parts of polyacrylonitrile fiber, 20 parts of hemp fiber, 8 parts of sodium hydroxyethyl cellulose, over 5 parts ammonium sulfate and 4 parts polyurethane. The cotton fiber and the polyacrylonitrile fiber are helically twisted as a warp fiber bundle, the soybean fiber and the hemp fiber are helically twisted as a weft fiber bundle, and the warp fiber bundle and the weft fiber bundle are sequentially interwoven into a twill weave organizational u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com