Fixing support for double-output-shaft external rotor electric motor

A technology for external rotor motors and fixed brackets, applied in the direction of casings/covers/supports, electrical components, electromechanical devices, etc., can solve the problems of poor strength and insufficient rigidity at the connection position, and achieve good overall quality, convenient replacement, and guaranteed Effects of Strength and Rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

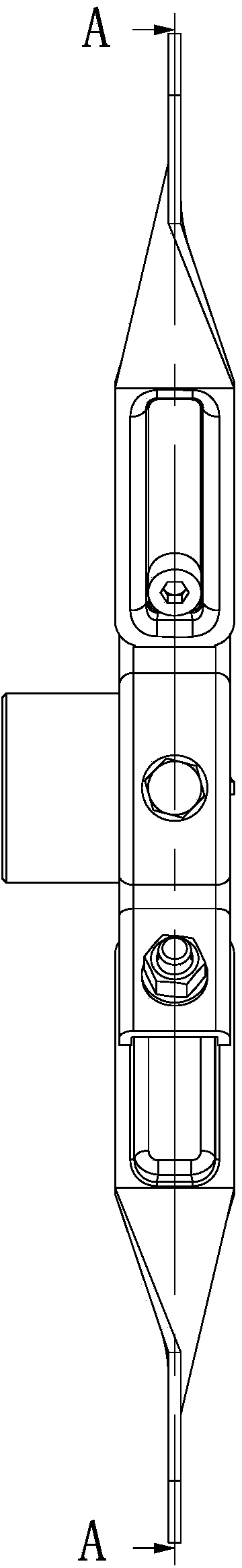

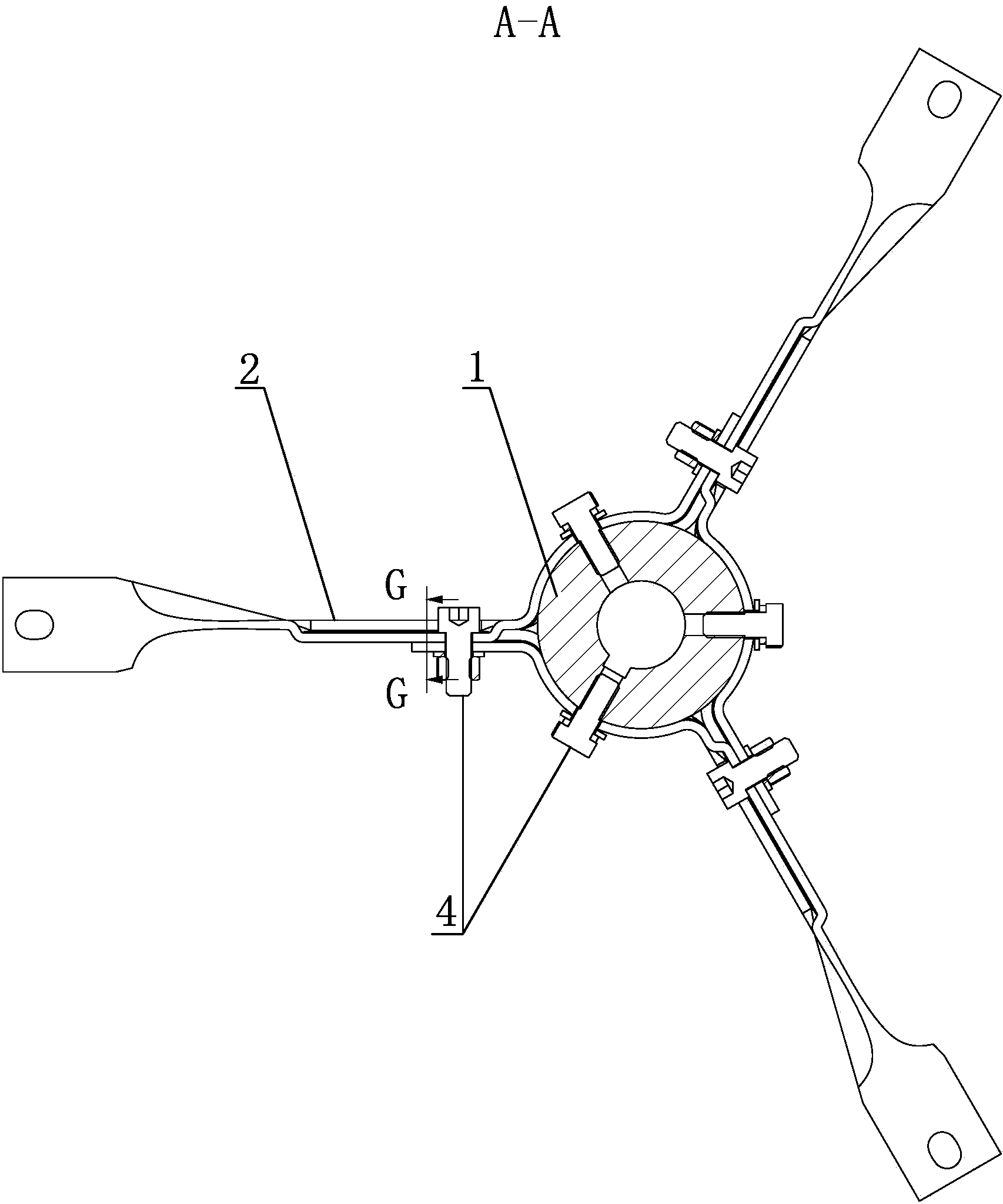

[0021] Such as figure 1 , 2 A fixed bracket for a double-outlet external rotor motor shown includes a shaft sleeve 1 and a plurality of support rods 2 connected to the shaft sleeve 1 . Specifically:

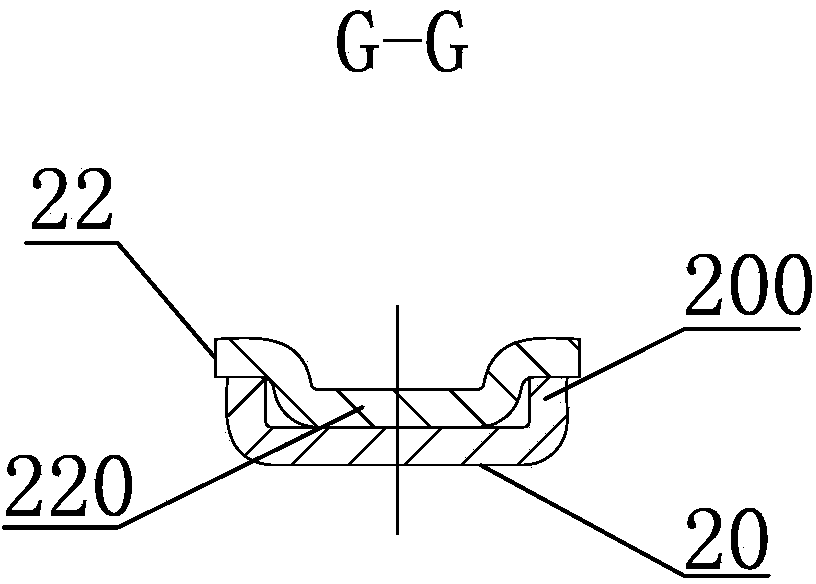

[0022] Such as Figure 4 , 5 As shown: the support rod 2 has a connecting head 20, a shaft sleeve matching portion 21 and a connecting tail portion 22, wherein: the connecting head 20 is provided with a first hem 200, and a connecting hole 3 is opened; The second flange 210 is provided, and the connecting hole 3 is also opened. The shape of the shaft sleeve matching part 21 is consistent with the outer peripheral shape of the shaft sleeve 1. The outer circumference of the shaft sleeve 1 is a circle, so the shaft sleeve matching part 21 is 1 / n Circumference, n is the number of support rods 2; the connecting tail 22 is provided with an outwardly prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com