Self-unloading compartment structure with strengthened bottom plate and auxiliary frame

A subframe and reinforced technology, which is applied in the substructure, loading and unloading vehicle arrangement, motor vehicles, etc., can solve the problems of material strength loss, achieve the effect of increasing strength, reducing the strength loss of base material, and ensuring strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

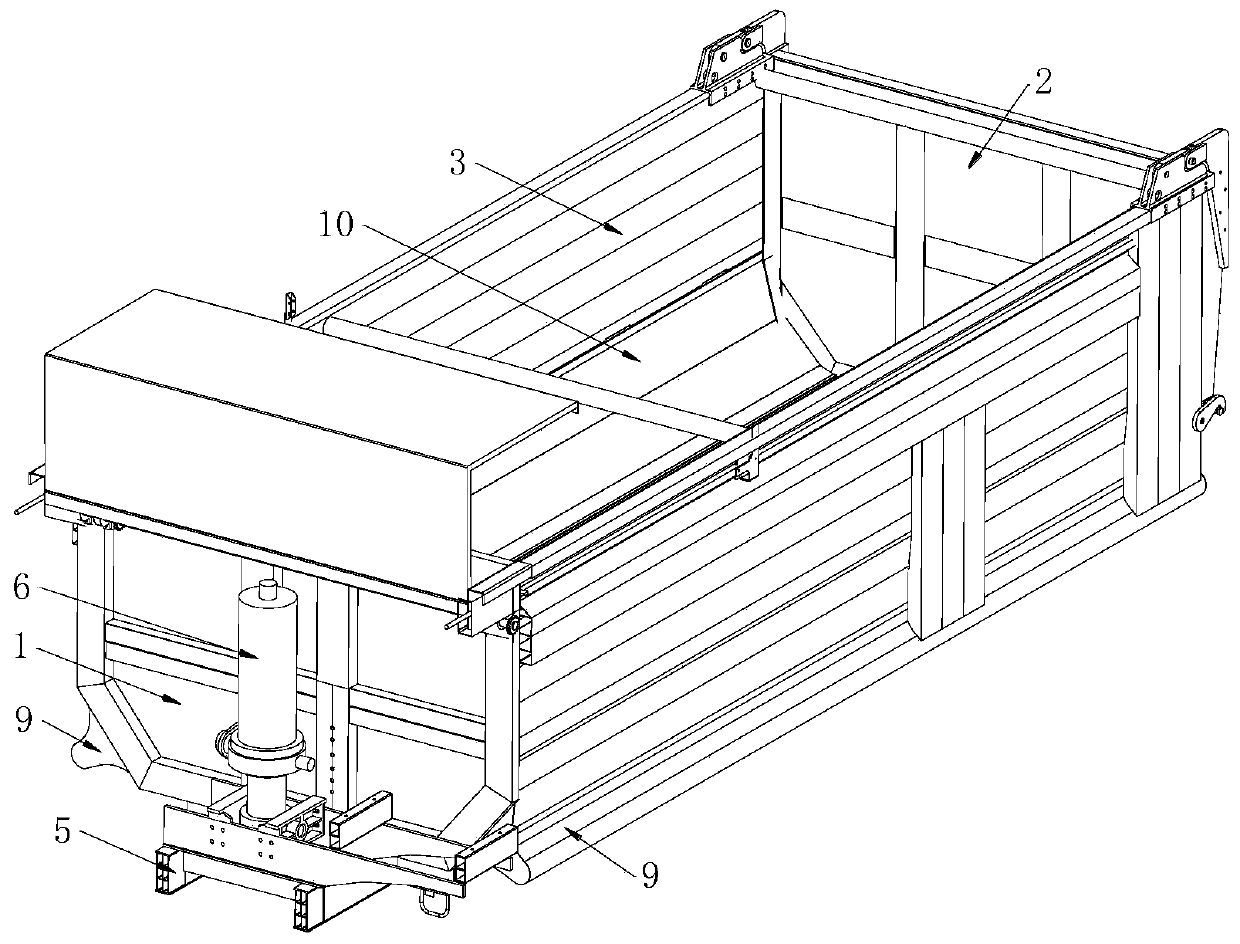

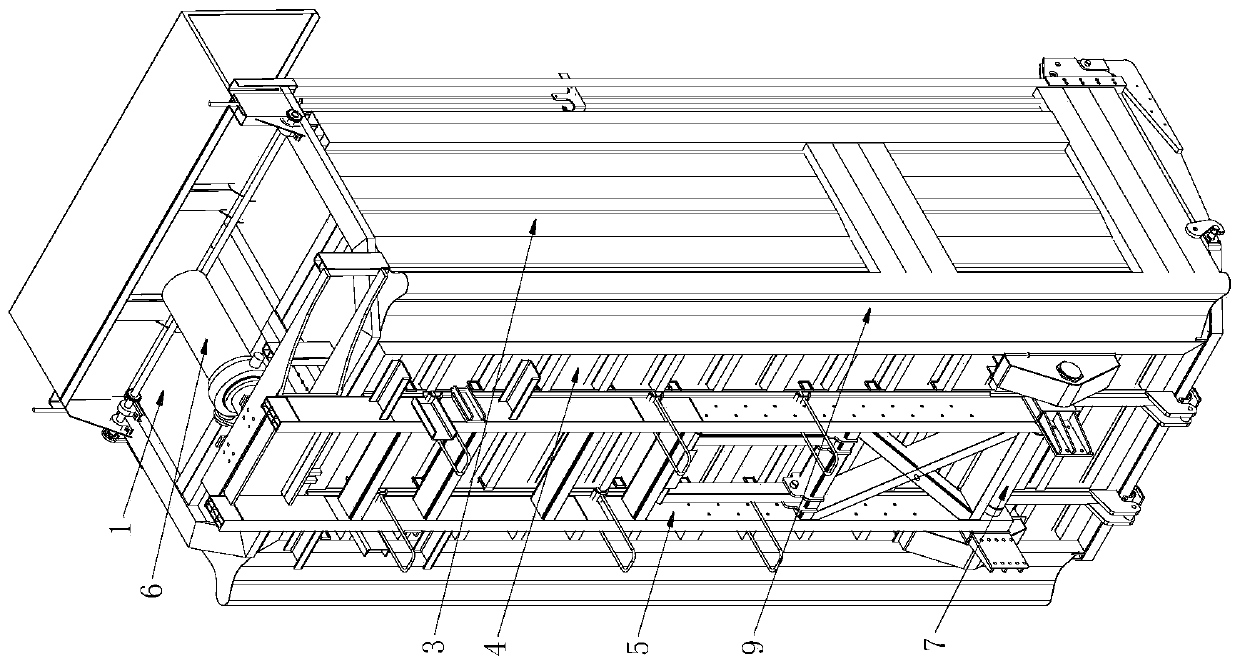

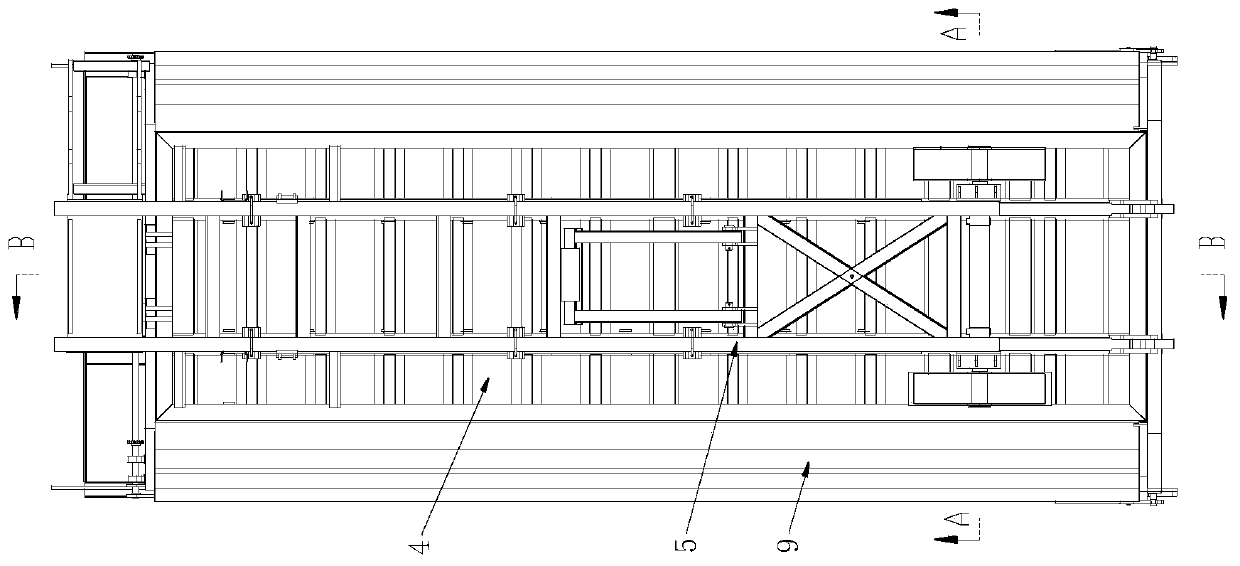

[0042] Such as Figure 1 to Figure 18 As shown, the dump car structure described in this embodiment includes an aluminum front compartment panel 1, a rear compartment panel 2, two symmetrically arranged side compartment panels 3 and a compartment floor 4, and the bottom of the compartment floor 4 is also A subframe 5 is provided through which the compartment is connected to the underframe of the vehicle. The front side of the subframe 5 is connected to the compartment floor 4 through a jacking mechanism 6. The rear side is pivotally connected with the rear side of the compartment floor 4 through the rotating shaft 7 to realize the lifting of the compartment and realize the cargo self-unloading process. At the same time, the side compartment plate 3 and the compartment floor 4 are also connected by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com