Method for producing highly dimensionally stable half shells and device for producing a half shell

A dimensionally stable and bearing bush technology, which is applied in the field of the second mold, can solve the problems of complex tools for deep drawing parts, and achieve the effect of dimensionally stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

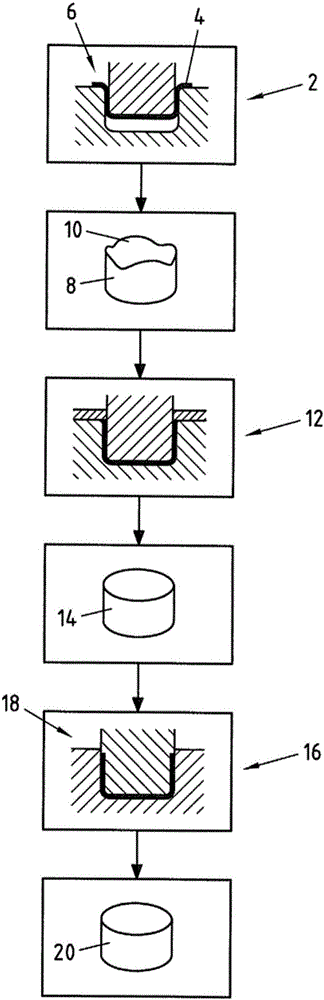

[0033] Figure 1 shows a method for producing a highly dimensionally stable bearing shell according to the prior art. In a first step 2 , the plate 4 is deep drawn in a first die 6 . After the deep-drawing process 2 , the bearing shell 8 produced in this way has a dimensionally stable tip 10 which reduces the preformed bearing shell 8 . In a next step 12 , the tip 10 is removed by cutting the bearing shell 8 . This process can either be carried out in another tool or integrated in the first deep drawing process 2 . After the final cut 12, the frame area of the flangeless bearing shell 14 has the desired target height. As a result of the deep-drawing process 2 , the bearing shell 14 has dimensional inaccuracies that can be removed in the subsequent final forming 16 by means of the calibration tool 18 . Finally, a highly dimensionally stable bearing shell 20 is produced in this way. The disadvantage of this method is that, since the cutting 12 prolongs the process chain for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com