Magnetic impulse warm-hot dynamic drive forming device and forming method for titanium alloy plate

A titanium alloy and magnetic pulse technology, which is applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of not very fine structure of formed workpieces, reduced strength and wear resistance, low utilization rate of magnetic field efficiency, etc., to achieve Overcoming lubrication and material and environmental pollution, reducing deformation resistance, and improving strain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The thickness of the TA20 titanium alloy plate used is 1-2mm, and the size is 100mm×100mm; its chemical composition is shown in Table 1.

[0082]

[0083] Material preparation: Before the TA20 titanium alloy sheet is subjected to magnetic pulse thermal dynamic drive forming, uniform annealing treatment is performed first, and the annealing temperature is 550-600°C.

[0084] The die material and steel sleeve material are all made of No. 45 steel to reduce electromagnetic losses;

[0085] The thickness of the aluminum driver plate is 2mm.

[0086] The forming method is carried out as follows:

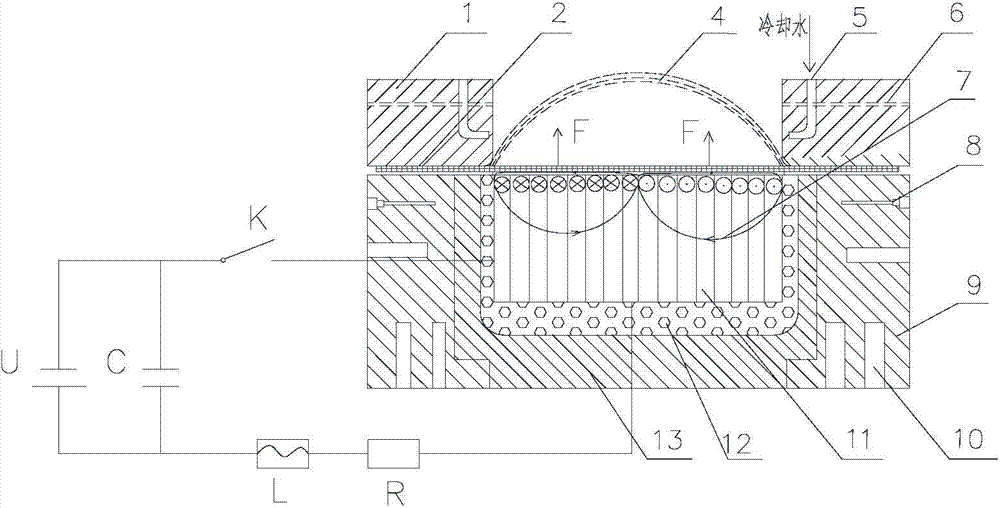

[0087] In the first step, the electromagnetic forming coil 11 is inserted into the electromagnetic forming coil housing 13, and the gap between the two is densely filled with the pouring filler 12. After the filler is poured, it is cured at room temperature for 4 hours, and then placed in an oven at 80°C Heat preservation for 2 hours to obtain the electromagnetic forming coil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com