Coil-free electromagnetic-pulse forming device and method of metal plates

A metal sheet and electromagnetic pulse technology, applied in the field of material plastic forming, can solve the problems of high cost of coil production, high conductivity, easy failure, etc., and achieve the effect of improving the forming limit, high service life and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

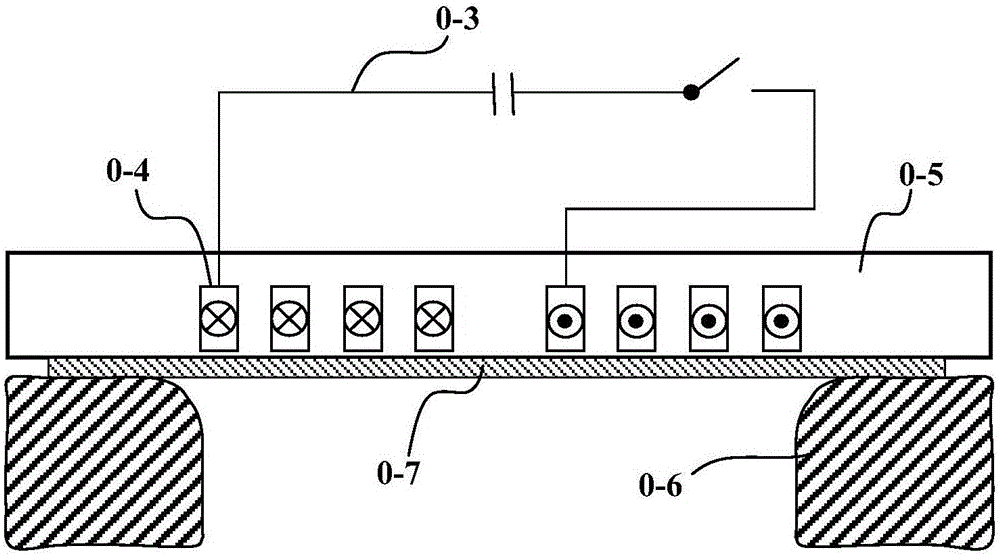

[0040] like figure 2 Shown is the coilless electromagnetic pulse forming device for metal sheets of the present invention, including a die 1, a pressing plate 3, an induction plate 4, and a power supply system 6; the pressing plate 3 presses the plate 2 on the die 1, and the induction plate 4 is arranged on The press plate 3 is located directly below the plate 2 to be formed, and its shape can be a cylinder, a truncated cone, a hexahedron or an irregular shape; the power supply system 6 includes parallel power supplies, energy storage capacitors, voltage dividing resistors and switches; the power supply system 6 and the The forming plates 2 are directly connected; both the pressing plate 3 and the die 1 are made of insulating materials. When the concave mold is made of metal material, an insulating material must be laid between the plate to be formed and the mold.

[0041] The specific process of forming by using the above-mentioned coilless electromagnetic pulse forming dev...

Embodiment 2

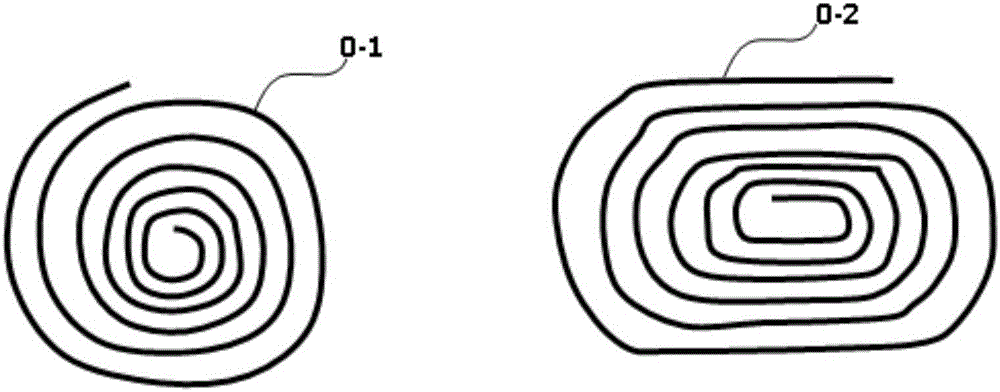

[0043] like Figure 4a The shown coilless electromagnetic pulse forming device for metal sheets is different from the device in Embodiment 1 in that there are two induction plates in the pressing plate, namely induction plate 4-1 and induction plate 4-2. Both induction plates are located on the same side of the plate 2 to be formed. The power supply system 6 includes a parallel power supply, energy storage capacitors, voltage divider resistors and switches; the power supply system 6 is directly connected to the plate to be formed 2-1; the pressing plate 3-1 and the die 1-1 are made of insulating materials. When the concave mold is made of metal materials, insulating materials must be laid on the contact between the plate to be formed and the contact.

[0044] The specific process of adopting the forming device of the above-mentioned metal plate without coil electromagnetic pulse forming device includes: placing the plate to be formed 2-1 between the pressing plate 3-1 and the...

Embodiment 3

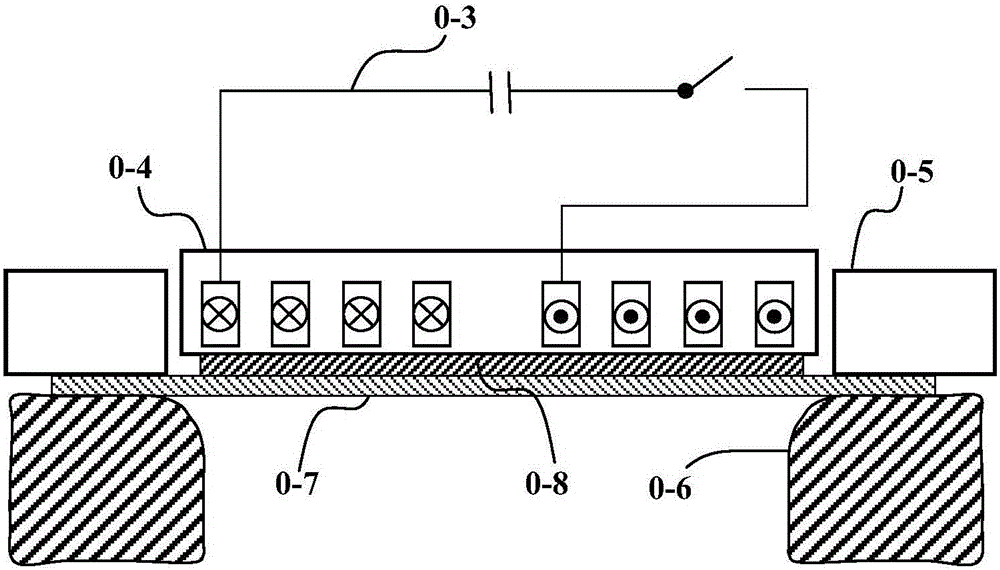

[0046] like Figure 4b The shown coilless electromagnetic pulse forming device for metal sheets differs from the device in Embodiment 2 in that the induction plate 4-3 and the induction plate 4-4 in the pressing plate are respectively located on both sides of the sheet to be formed 2-2. The power supply system 6 includes a parallel power supply, energy storage capacitors, voltage dividing resistors and switches; the power supply system 6 is directly connected to the plate to be formed 2-2; the die press plate assembly 1-2 and the die press plate assembly 3-2 are both The concave mold acts as a pressing plate again, and is made of insulating materials. When the part of the die is assembled with metal materials, insulating materials must be laid at the contact between the plate to be formed and the die.

[0047] The specific process of adopting the above-mentioned sheet metal forming device without coil electromagnetic pulse forming includes: placing the plate to be formed 2-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com