Multistage and multidirectional electromagnetic forming method and device

An electromagnetic forming and magnetic field technology, which is applied in the field of forming processing and manufacturing, can solve the problems of low energy density, poor mold-fitting performance, and difficulty in realizing a single deep processing of the workpiece, and achieve the effect of increasing the forming depth and improving the mold-fitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

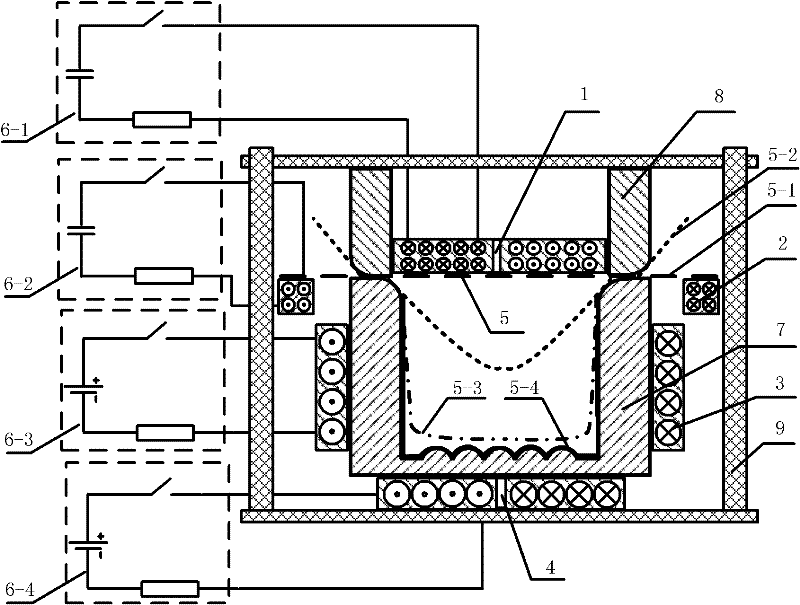

[0022] The multi-stage multi-directional electromagnetic forming device includes an induction eddy current coil, an auxiliary forming coil, an electromagnetic coil, an electromagnetic suction coil and a blank holder ring.

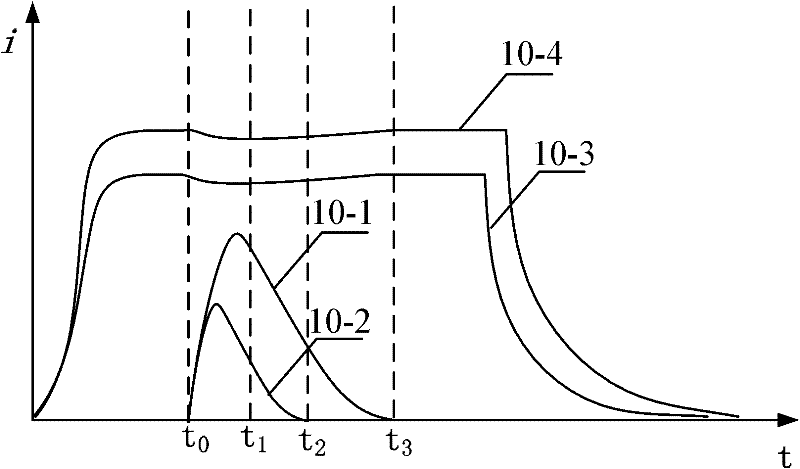

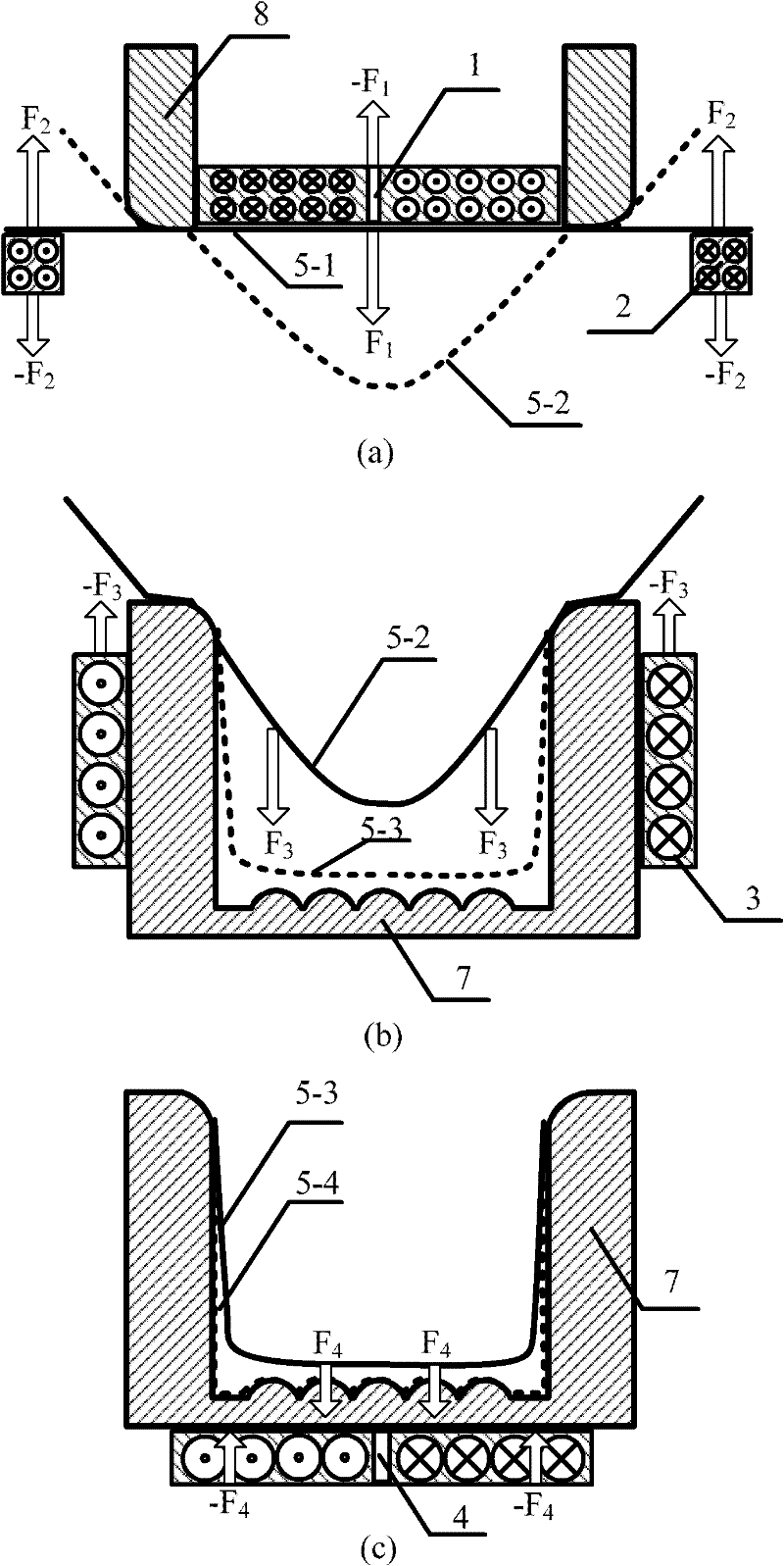

[0023] The induction eddy current coil 1 mainly provides multi-level pulse current ( figure 2 Shown long pulse current 10-1) or long pulse eddy current; described auxiliary forming coil 2 mainly produces a short pulse current ( figure 2 The shown short pulse current 10-2) provides a reverse preforming for the workpiece, so that the workpiece flows into the die more easily; the electromagnetic coil 3 mainly provides an electromagnetic repulsion for the workpiece to promote the continuous acceleration of the workpiece; the electromagnetic The suction coil 4 mainly provides an electromagnetic suction force for the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com