Blister forming machine

A molding machine and molding mechanism technology, applied in the direction of packaging, etc., can solve problems such as uneven thickness, rough surface of blisters, and affecting the aesthetics of blisters, etc., to achieve improved molding depth, prominent substantive features, and convenient installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

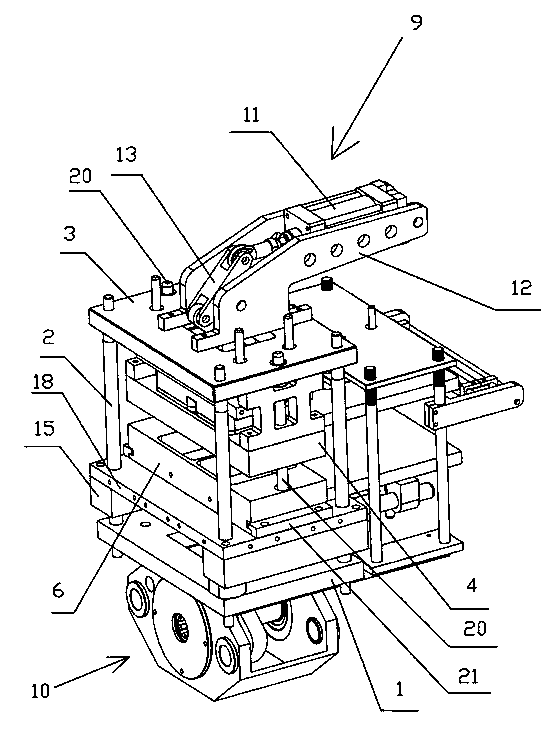

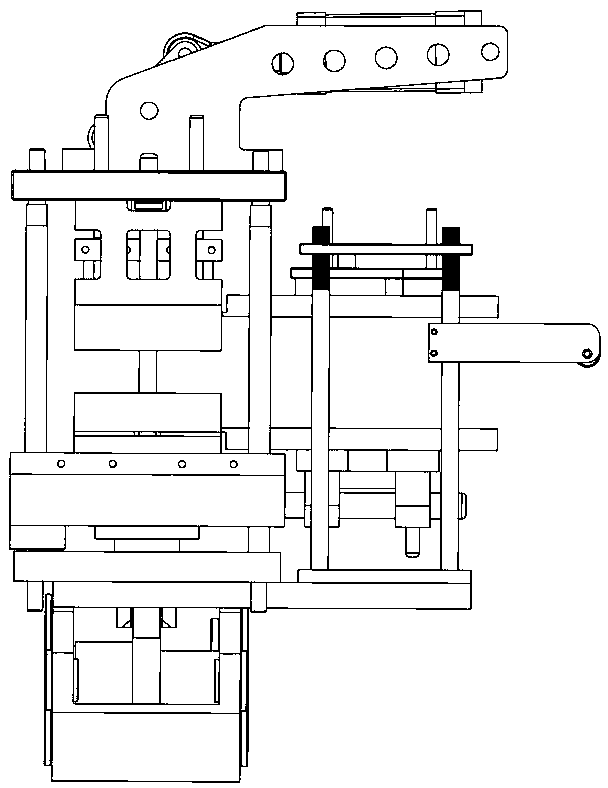

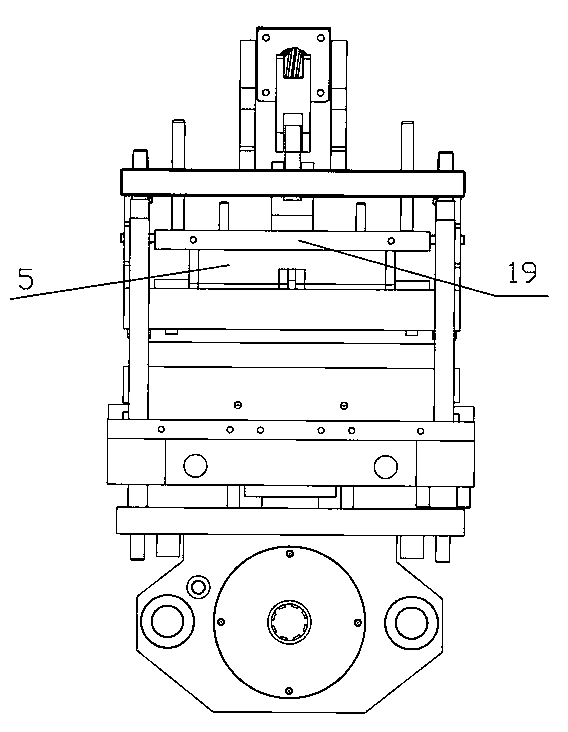

[0026] Referring to the accompanying drawings, a blister forming machine in this embodiment includes an organic base 1, and the base is provided with a forming mechanism, and the forming mechanism includes a column 2 arranged on the base, fixedly arranged on the column The upper mold base 3 on the top and the forming upper mold 4 fixedly arranged below the upper mold base, the first cavity 7 is provided in the forming upper mold, and the first cavity is provided with the first transmission mechanism 9. The forming punch 5 is movable up and down, and then the forming punch moves up and down through the transmission of the first transmission mechanism. In this embodiment, the first transmission mechanism includes a cylinder, and the upper mold base is provided with a wallboard. The air cylinder is arranged on the installation wallboard, the piston rod of the air cylinder is arranged vertically, and the air cylinder is connected with the forming punch in transmission. The forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com