Device and method for improving die attaching performance of electromagnetic formed workpiece

An electromagnetic forming and workpiece technology, which is applied in the field of metal forming and manufacturing, can solve the problems such as the difficulty of attaching the workpiece to the mold, and achieve the effects of flexible replacement of the magnetic collector, increased flexibility, and short processing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

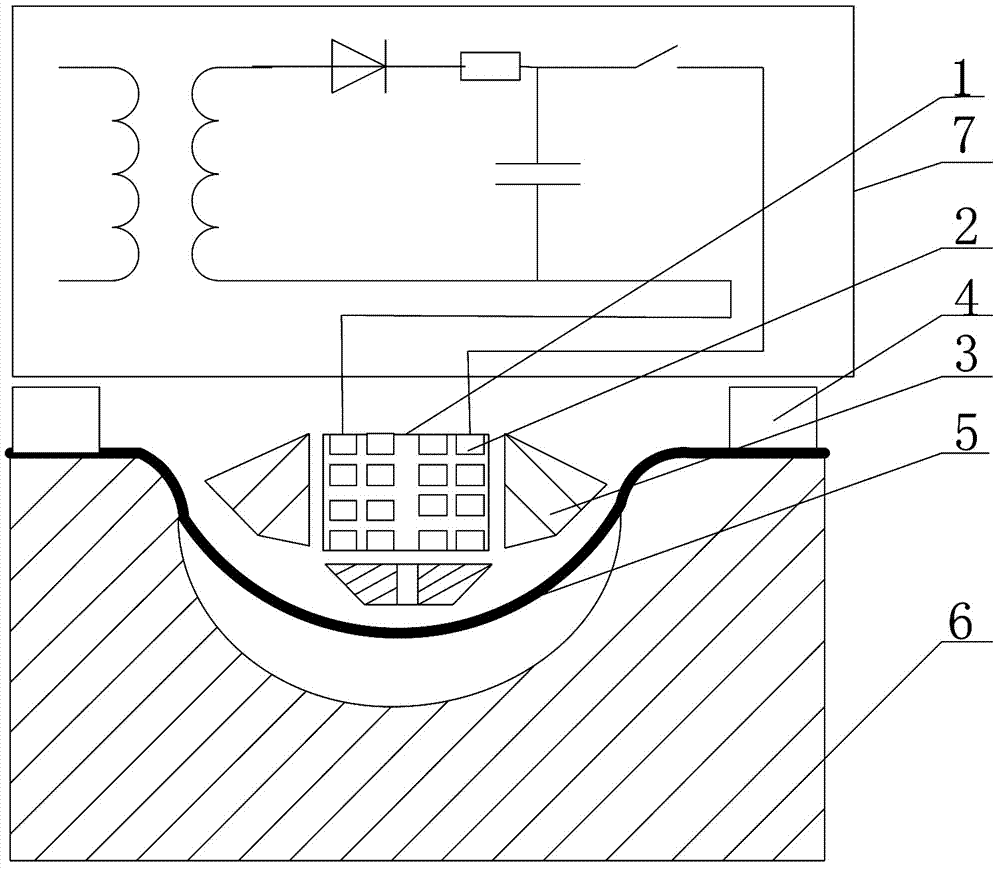

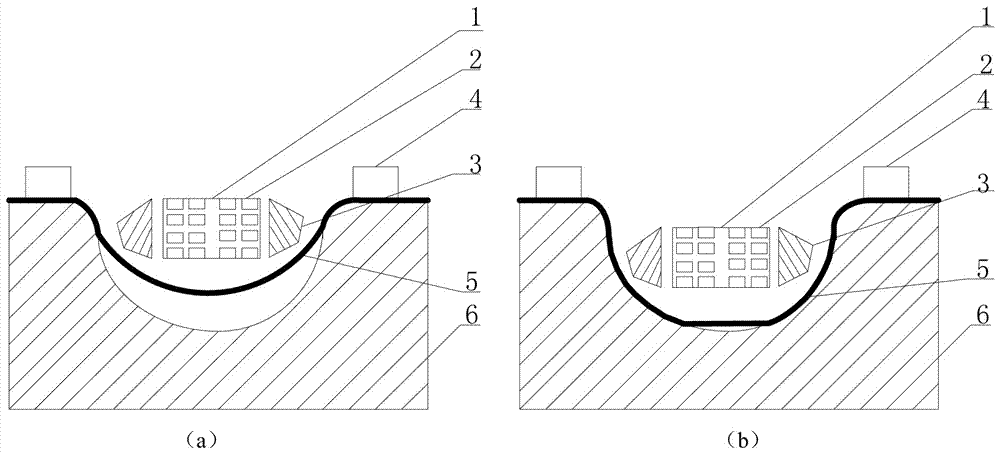

[0031] A method and device for improving the mold-fitting performance of electromagnetically formed workpieces described in the present invention. In order to make the technical solutions and advantages of the present invention more clear, the present invention will be described in detail in conjunction with the accompanying drawings. In particular, the specific examples described here are only used to explain the present invention, not to limit the present invention.

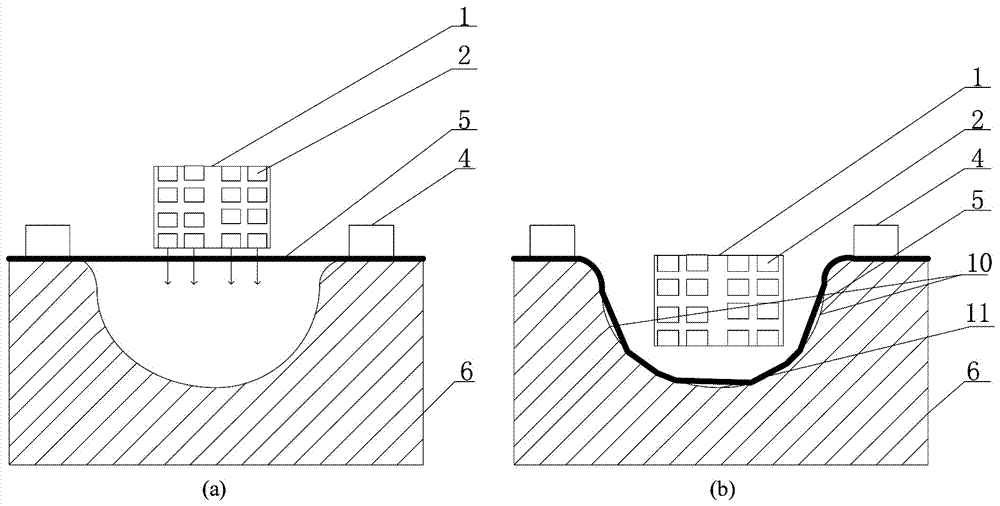

[0032] The specific implementation plan of the electromagnetic forming device before improvement is as follows:

[0033] The mold adopts a hemispherical shape, such as figure 2 As shown in (a), the aluminum alloy plate 5 is placed directly above the hemispherical mold 6, fixed by the blank holder 4, the driving coil 2 is fixed on the slider 1, the driving coil 2 is connected to the capacitor power module 7, and the driving coil 2. The centers of the hemispherical mold 6 and the aluminum alloy plate 5 are coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com