Steel plate electromagnetic hot stamping production line and hot stamping forming method thereof

A hot stamping and production line technology, which is applied in the electromagnetic hot stamping production line of steel plate and its hot stamping forming field, can solve the problems of not being able to obtain hot stamping workpieces and affecting the forming accuracy, and achieve rapid prototyping, not easy to rebound, and prevent thinning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

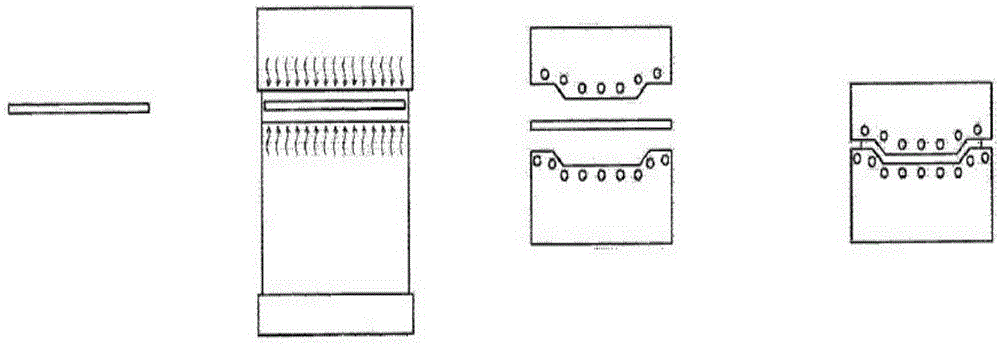

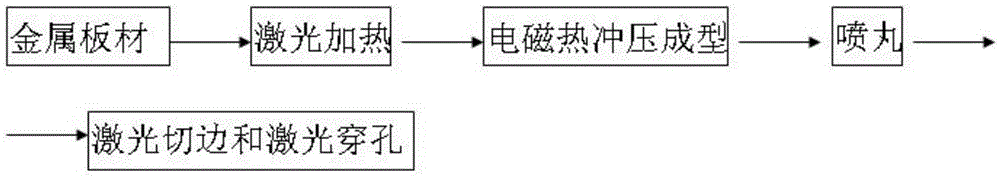

[0028] Such as figure 2 As shown, a steel plate electromagnetic hot stamping production line, which sequentially includes a strip uncoiling station, a strip transmission track, a blanking station, a blanking transfer basket, a blanking blank transfer manipulator, a heating station, and a heating blank transfer device , hot stamping and quenching station, hot stamping billet transfer manipulator, hot stamping billet transfer basket, shot blasting feeding manipulator, shot blasting station, shot blasting billet transfer track, laser cutting and perforating station, inspection and packaging storage station .

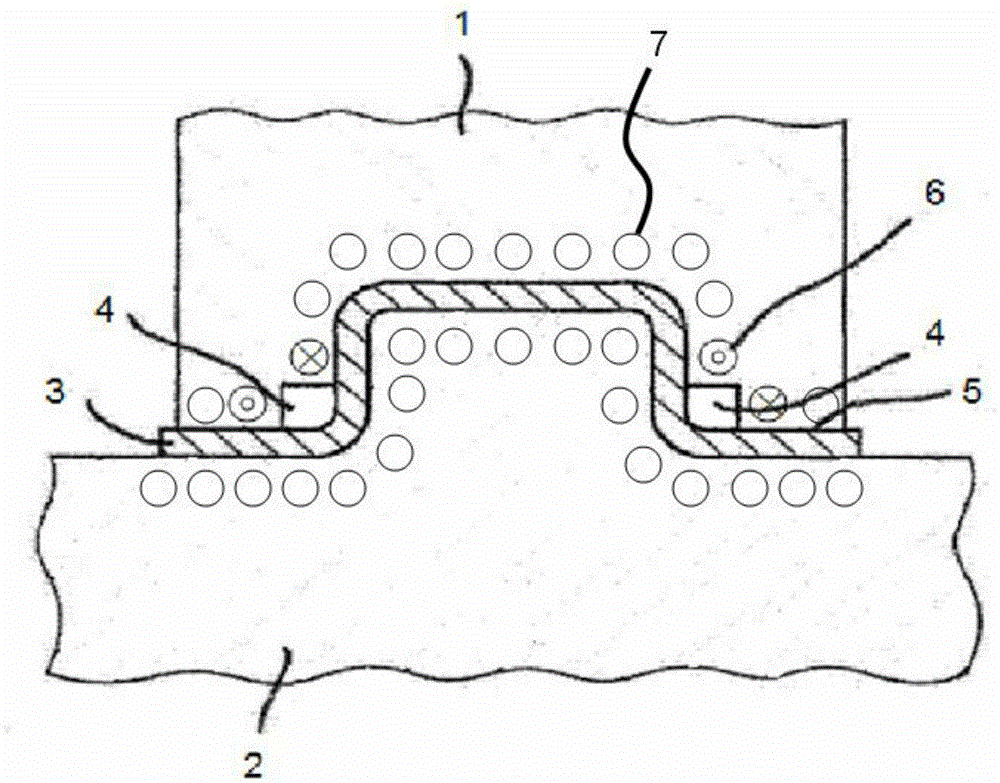

[0029] The hot stamping quenching station includes a hot stamping press and its control system and a hot stamping die, the hot stamping die includes an upper die 1 and a lower die 2, and several cooling passages 7 are arranged in the upper die a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com