Electromagnetic forming device of sheet metal

An electromagnetic forming and metal sheet technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unclear formation of micro-structure patterns, increased processing costs, and uneven magnetic field distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

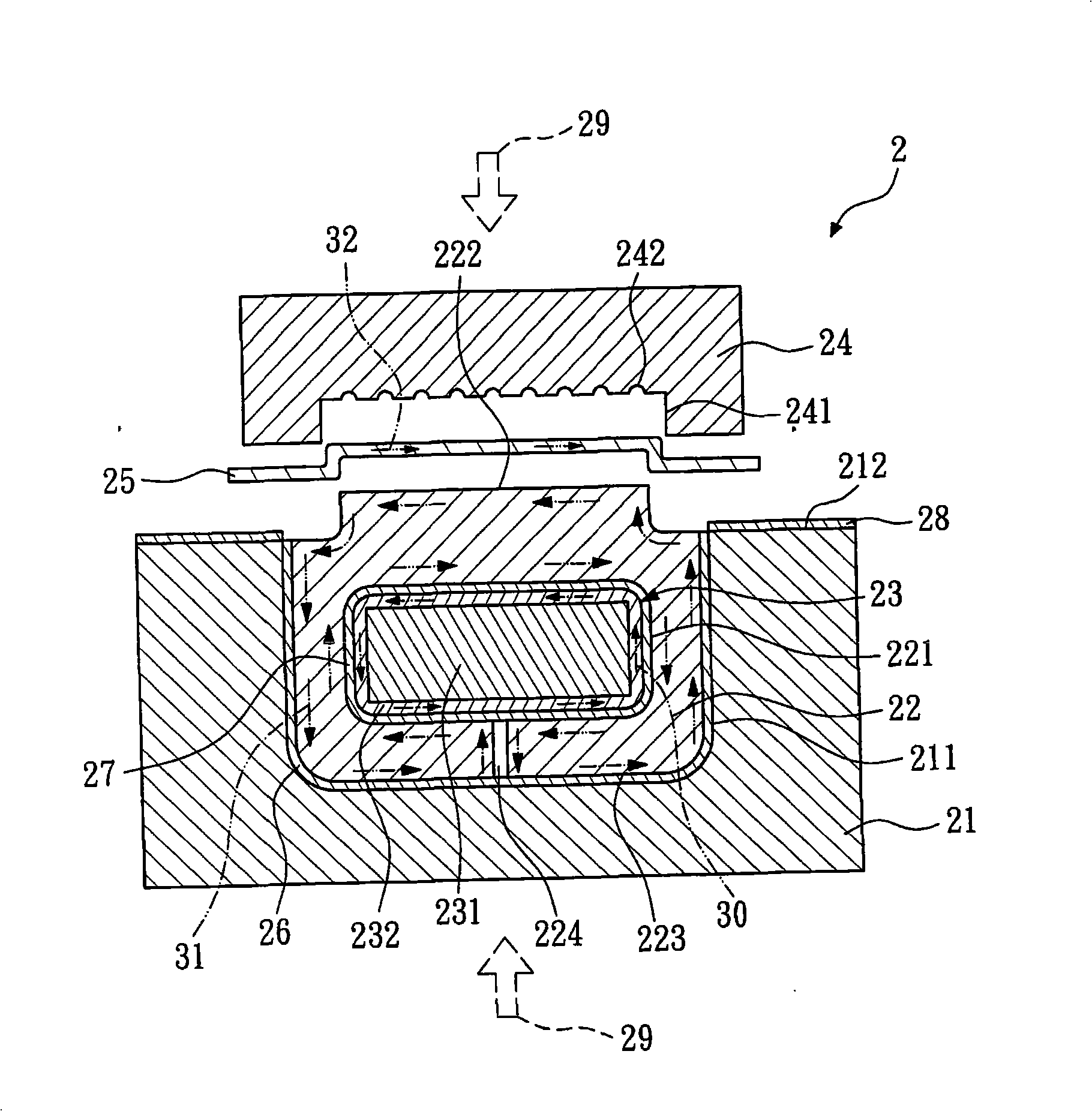

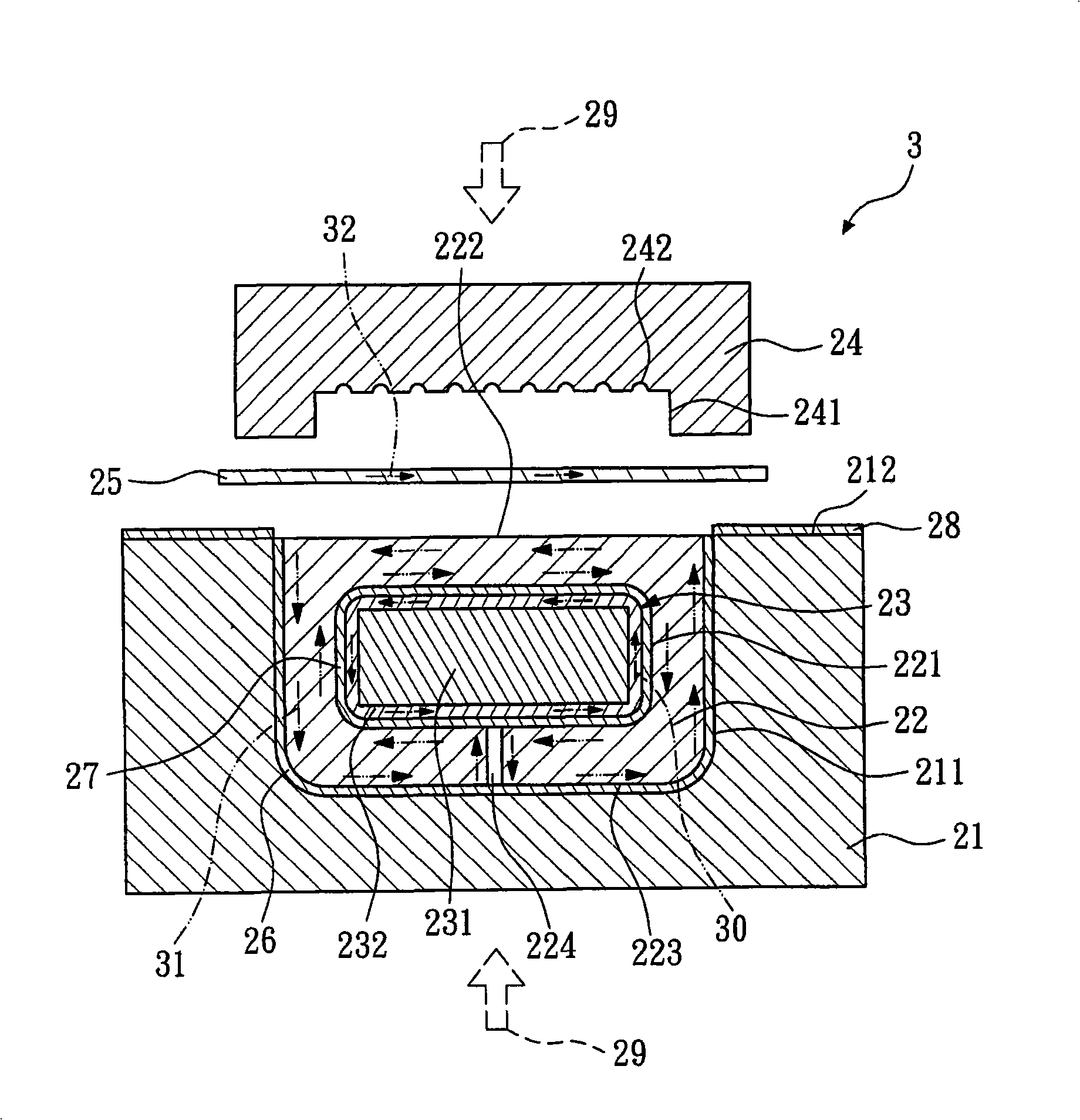

[0011] see figure 2 , shows a schematic cross-sectional view of the first embodiment of the electromagnetic forming device for sheet metal according to the present invention. The electromagnetic forming device 2 includes a fixed seat 21 , a magnetic collecting block 22 , an electromagnetic generating device 23 and a mold 24 . The fixing seat 21 has a slot 211 and a first surface 212 , and the slot 211 opens on the first surface 212 . The magnetic collecting block 22 is located in the slot 211 of the fixing seat 21 , and the magnetic collecting block 22 has an accommodating space 221 , a first surface 222 , a second surface 223 and a gap 224 . The accommodating space 221 is located inside the magnetic collecting block 22 and is connected to the second surface 223 of the magnetic collecting block 22 through the gap 224, but it is not limited thereto, and the accommodating space 221 is also The first surface 222 of the magnetic collecting block 22 can be communicated through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com