Multi-directional hydraulic extrusion press for semi-solid metal forming

A semi-solid metal, multi-directional extrusion technology, which is applied in the field of multi-directional extrusion hydraulic presses for semi-solid metal forming, can solve the problems of non-adjustable hydraulic cylinders, inconvenient mold loading, and unfavorable adjustments, so as to facilitate installation and fixation , to ensure the effect, to overcome the effect of uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

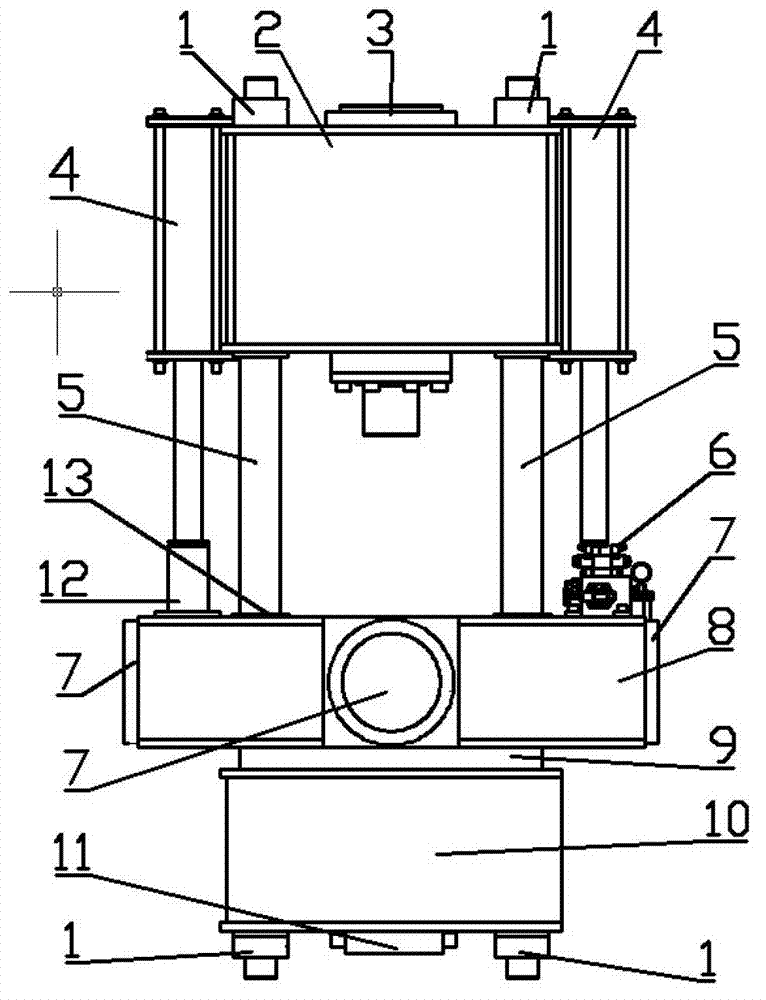

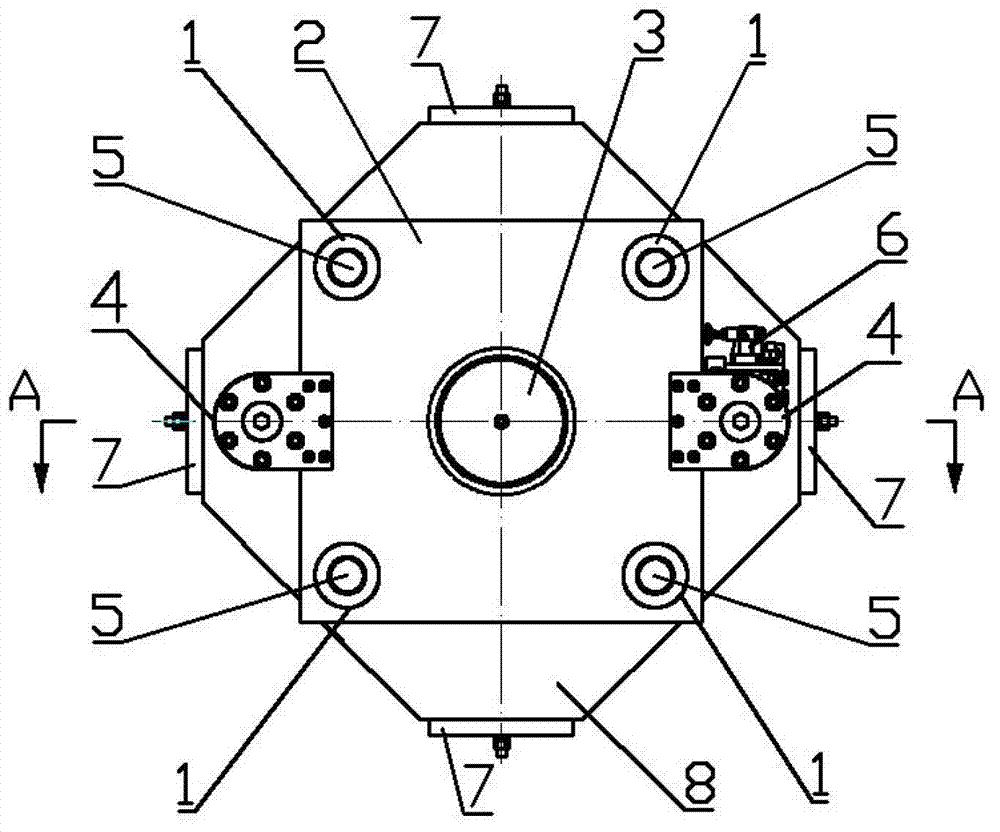

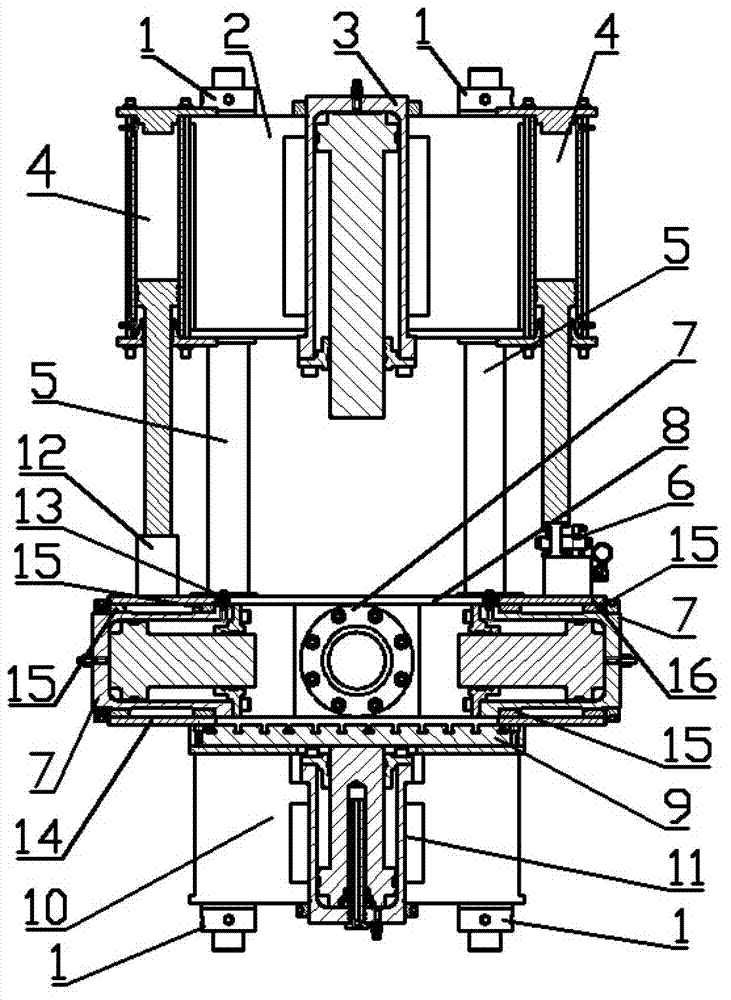

[0014] refer to figure 1 , figure 2 and image 3 , a multi-directional extrusion hydraulic press for semi-solid metal forming, comprising a cuboid-shaped upper beam 2, a cuboid-shaped lower beam 10 and a moving beam 8, a through hole is opened at the center of the upper beam 2 and the upper beam piston cylinder is installed 3. Open a through hole at the center of the lower beam 10 and install the inner piston cylinder 11 of the lower beam. There are four through holes at the four corners of the upper beam 2. Four through holes are opened at the four corners of the lower beam 10. holes, the tops of the four locking rods 5 respectively pass through the four through holes at the four corners of the upper beam 2, the lower surface of the upper beam 2 contacts and presses the shoulders on the four locking rods 5, and the four The tail ends of the locking rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com