Aluminum alloy curved part electromagnetic compound forming method and device

A technology of curved surface parts and electromagnetic compounding, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., to achieve uniform plastic deformation, improve forming accuracy, and avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

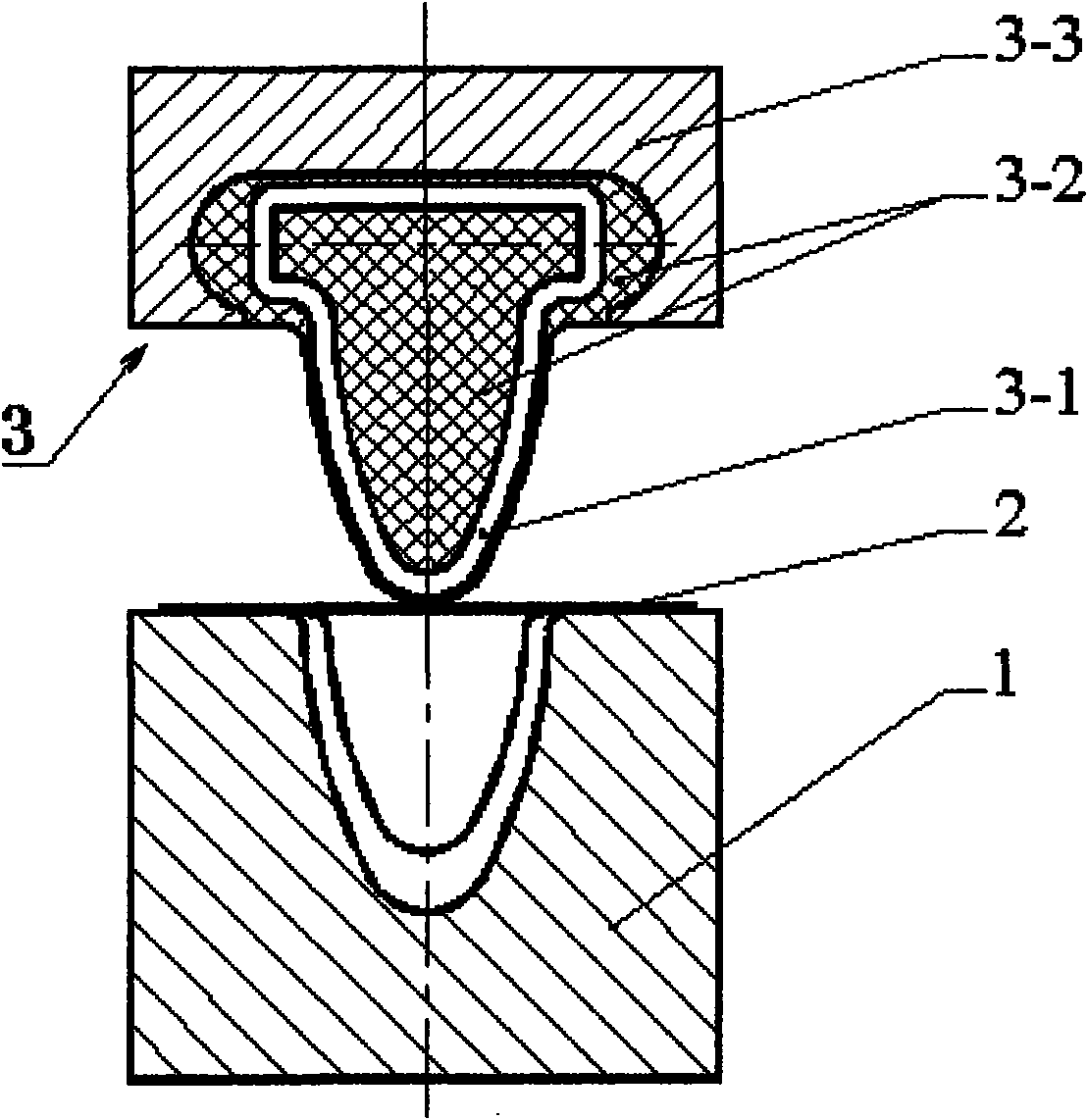

[0037] Example 1 Electromagnetic Composite Forming Experiment of Aluminum Alloy Curved Surface Parts

[0038] The experimental material is 1060 aluminum plate, the plate size is 100mm×150mm, and the thickness is 0.4mm, 0.7mm and 0.9mm. exist figure 1 Electromagnetic composite forming is performed on the tooling shown.

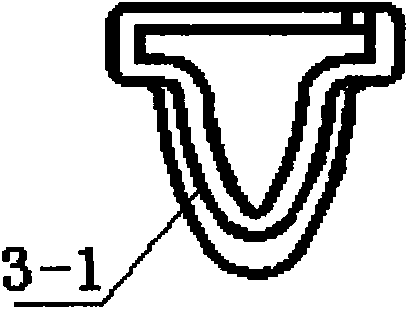

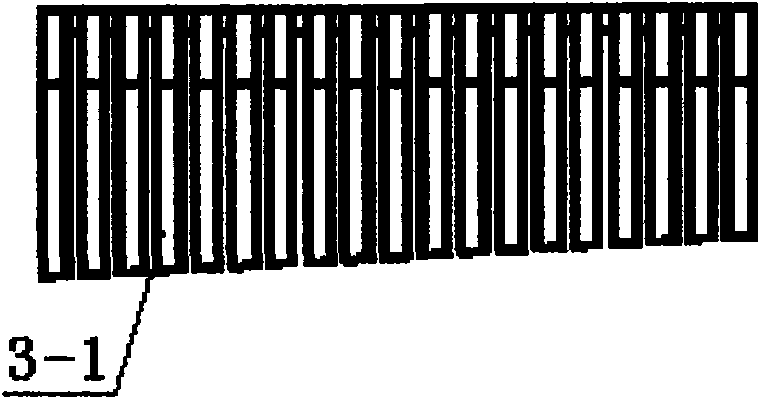

[0039] In the experiment, in the first stage, the coil punch 3 presses the aluminum alloy slab into the forming die 1 under the action of the press for pre-forming, and keeps the formed coil shell 3-3 in good contact with the flange edge of the aluminum alloy slab. Contact; in the second stage, adjust the energy storage capacitor and discharge voltage parameters of the electromagnetic forming machine, and discharge and form the aluminum alloy slab under different discharge energies. Forming analysis The amount of springback after the workpiece is taken out of the die, the amount of springback is the difference between the opening angle value of the small end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com