Polyether-ether-ketone composite material containing fluorapatite and titanium dioxide and preparation method thereof

A technology of titanium dioxide and polyetheretherketone, which is used in medical science, prosthesis, etc., can solve problems such as elastic modulus mismatch, stress shielding, loosening of bone restorations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

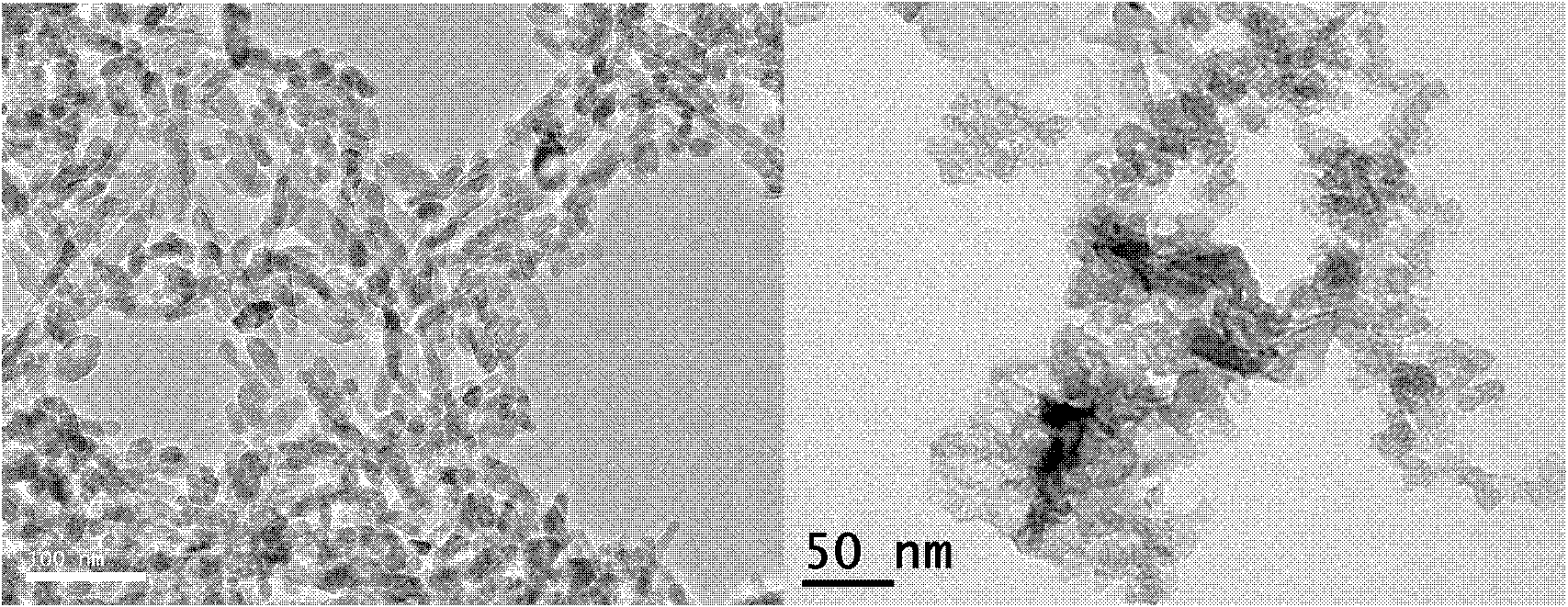

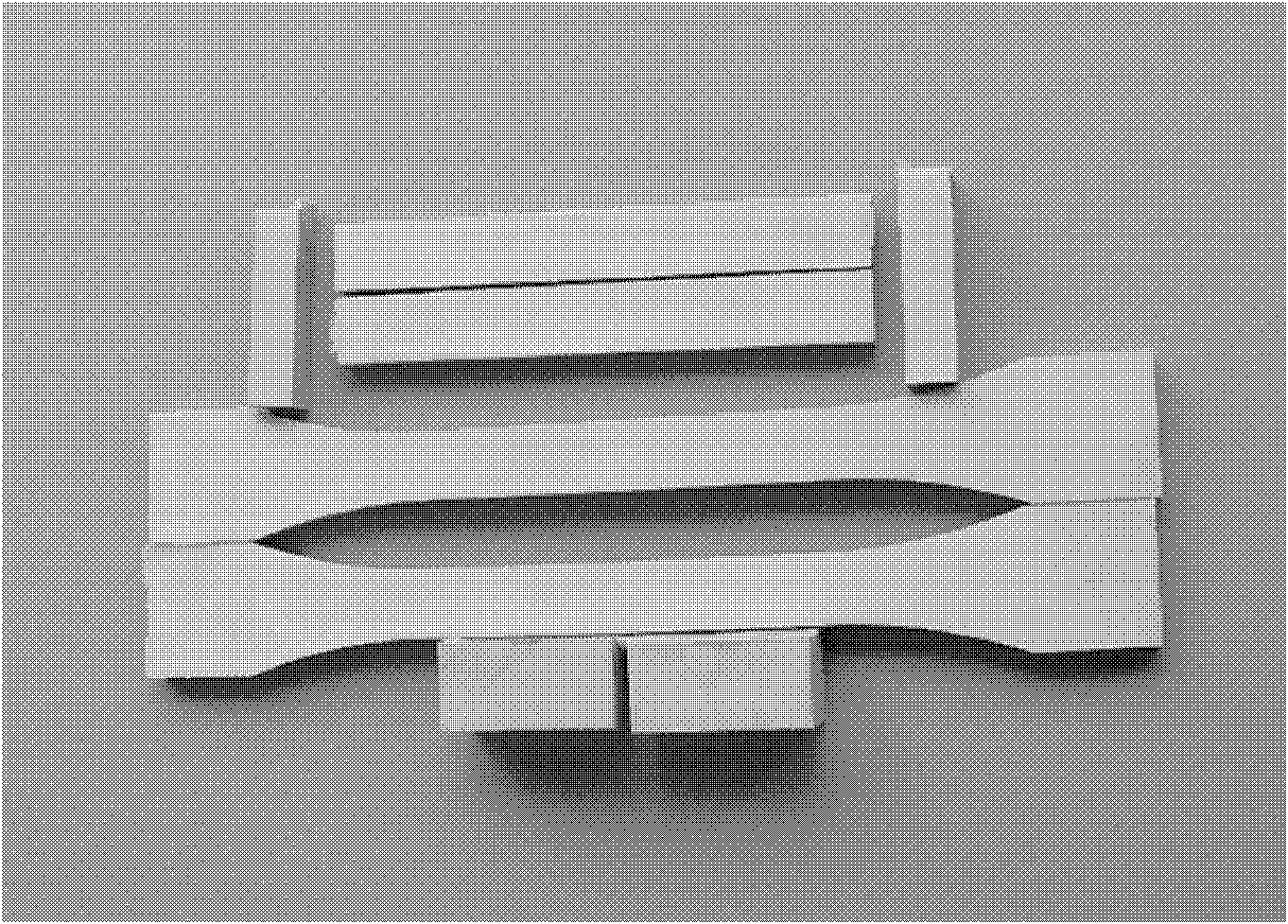

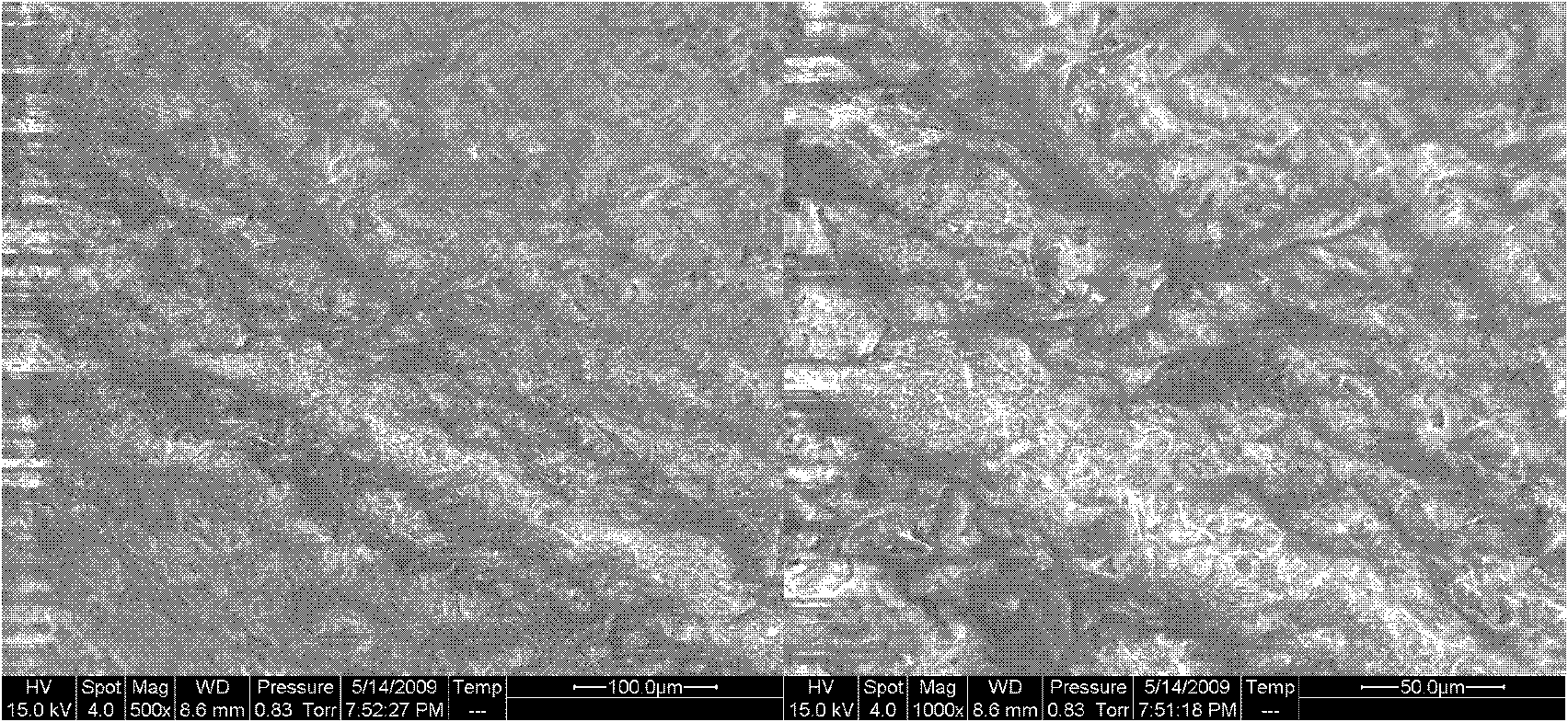

Image

Examples

Embodiment 1

[0049] The composition and weight percentage of the fluorapatite and titanium dioxide / polyetheretherketone composite material are: 20% of fluorapatite, 20% of titanium dioxide, and 60% of polyetheretherketone. Weigh 2kg of fluoroapatite, 2kg of titanium dioxide and 6kg of polyether ether ketone powder, pre-mix in a high-speed mixer, and then use a twin-screw extruder for high-temperature mixing, extrusion, and granulation. The particle composite material is injection-molded by an injection molding machine to form the required samples.

Embodiment 2

[0051] The composition and weight percentage of the fluorapatite and titanium dioxide / polyetheretherketone composite material are: 30% of fluorapatite, 10% of titanium dioxide, and 60% of polyetheretherketone. Weigh 3kg of fluoroapatite, 1kg of titanium dioxide and 6kg of polyether ether ketone powder, pre-mix in a high-speed mixer, and then use a twin-screw extruder for high-temperature mixing, extrusion, and granulation. The particle composite material is injection-molded by an injection molding machine to form the required samples.

Embodiment 3

[0053] The composition and weight percentage of the fluorapatite and titanium dioxide / polyetheretherketone composite material are: 20% of fluorapatite, 20% of titanium dioxide, and 60% of polyetheretherketone. Weigh 2kg of fluoroapatite, 2kg of titanium dioxide and 6kg of polyether ether ketone powder, pre-mix in a high-speed mixer, put the uniformly mixed powder of fluoroapatite and polyether ether ketone into the mold, and place the Put it into the press, raise the temperature from room temperature to 400°C, pressurize at 30MPa, keep the temperature and hold the pressure for 2-3 hours, and release the mold when the temperature is lowered to 100-120°C at a cooling rate of 10°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com