Preparation method for micron zirconium carbide whisker

A zirconium carbide and whisker technology, which is applied in the field of ultra-high temperature ceramic matrix composite material reinforcement preparation, can solve the problems of limited output of zirconium carbide whiskers, large experimental errors, and high equipment requirements, and achieve good shape, simple steps, and equipment undemanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

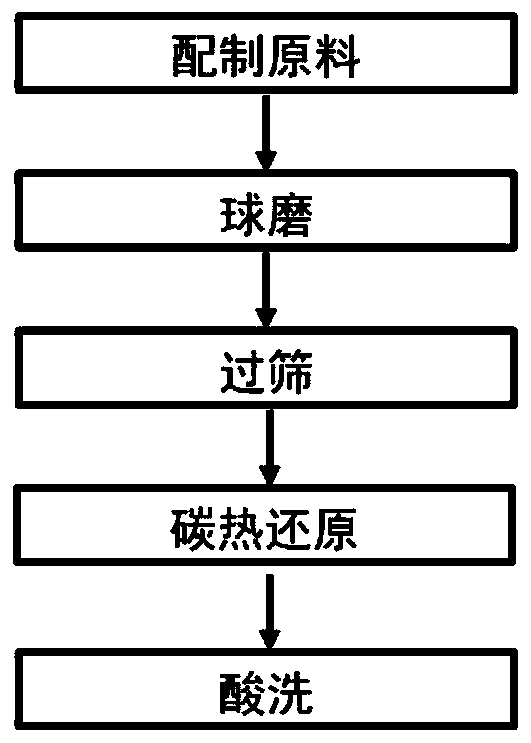

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Prepare raw materials for ball milling:

[0033] According to molar ratio ZrO 2 :C:Ni:NaF=1:3:0.2:0.1 Prepare 30g of raw materials, perform ball milling according to the mass ratio of ball to material=3:1, and the speed of rotation is 70r / min, and the ball milling time is 5h. A uniform precursor powder is obtained.

[0034] Step 2: Sifting:

[0035] The precursor powder obtained in step 1 is sieved with 100 meshes to obtain a powder with uniform particle size.

[0036] Step 3: Carbothermal Reduction

[0037] Weigh 2 g of the powder obtained in step 2, put it into a graphite crucible, and carry out carbothermal reduction reaction in a tube furnace. Reaction temperature: 1500°C, holding time: 4h, heating rate: 5K / min, atmosphere: Ar, Ar flow rate: 20cc / min, zirconium carbide whiskers were prepared by carbothermal reduction reaction.

[0038] Step 4: pickling to remove impurities

[0039] Prepare a sulfuric acid solution with a mass fraction of 70%, put the z...

Embodiment 2

[0041] Step 1: Prepare raw materials for ball milling:

[0042] According to molar ratio ZrO 2 :C:Ni:NaF=1:3:0.2:0.3 Prepare 30g of raw material for ball milling, perform ball milling according to mass ratio of ball to material=3:1, speed of 90r / min, ball milling time is 4h. A uniform precursor powder is obtained.

[0043] Step 2: Sifting:

[0044] The precursor powder obtained in step 1 is sieved with 100 meshes to obtain a powder with uniform particle size.

[0045] Step 3: Carbothermal Reduction

[0046] Weigh 2 g of the powder obtained in step 2, put it into a graphite crucible, and carry out carbothermal reduction reaction in a tube furnace. Reaction temperature: 1500°C, holding time: 4h, heating rate: 5K / min, atmosphere: Ar, Ar gas flow: 20cc / min, zirconium carbide whiskers were prepared by carbothermal reduction reaction.

[0047] Step 4: pickling to remove impurities

[0048] Prepare a sulfuric acid solution with a mass fraction of 70%, put the zirconium carbide ...

Embodiment 3

[0050] Step 1: Prepare raw materials for ball milling:

[0051]According to the molar ratio of ZrO2:C:Ni:NaF=1:4:0.2:0.3, 30g of raw materials were prepared, ball milling was carried out according to the mass ratio of ball to material=3:1, and the rotation speed was 90r / min, and the ball milling time was 5h. A uniform precursor powder is obtained.

[0052] Step 2: Sifting:

[0053] The precursor powder obtained in step 1 is sieved with 100 meshes to obtain a powder with uniform particle size.

[0054] Step 3: Carbothermal Reduction

[0055] Weigh 2g of the powder obtained in step 2, put it into a graphite crucible, and carry out carbothermal reduction reaction in a tube furnace. Reaction temperature: 1500°C, holding time: 4h, heating rate: 5K / min, atmosphere: Ar, Ar gas flow: 20cc / min, zirconium carbide whiskers were prepared by carbothermal reduction reaction.

[0056] Ni

[0057] Step 4: pickling to remove impurities

[0058] Prepare a sulfuric acid solution with a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com