Preparation method of novel neural restoration tissue engineering scaffold

A tissue engineering scaffold, nerve repair technology, applied in tissue regeneration, pharmaceutical formulations, pharmaceutical science and other directions, can solve the problems of low biocompatibility antigenicity, no promotion of tissue recovery and reconstruction, lack of biological activity, etc., to achieve comprehensive mechanics Excellent performance and stability, easy control of product shape and size, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

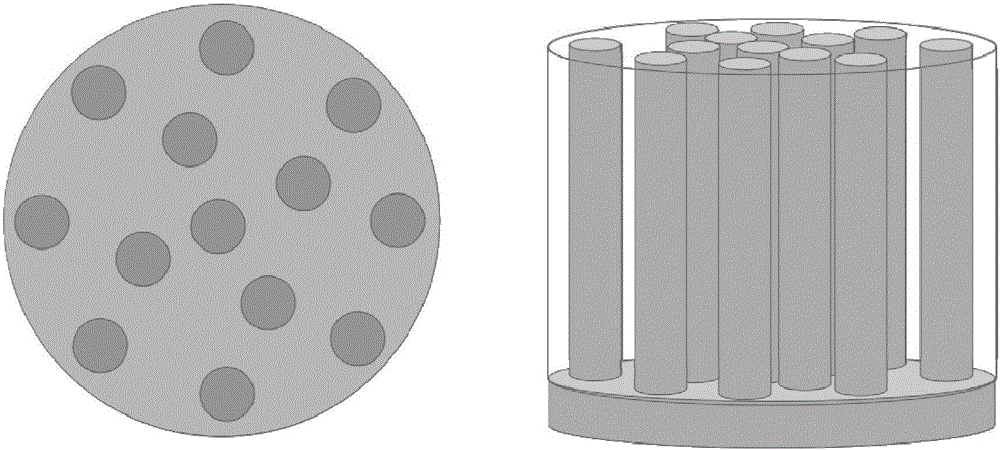

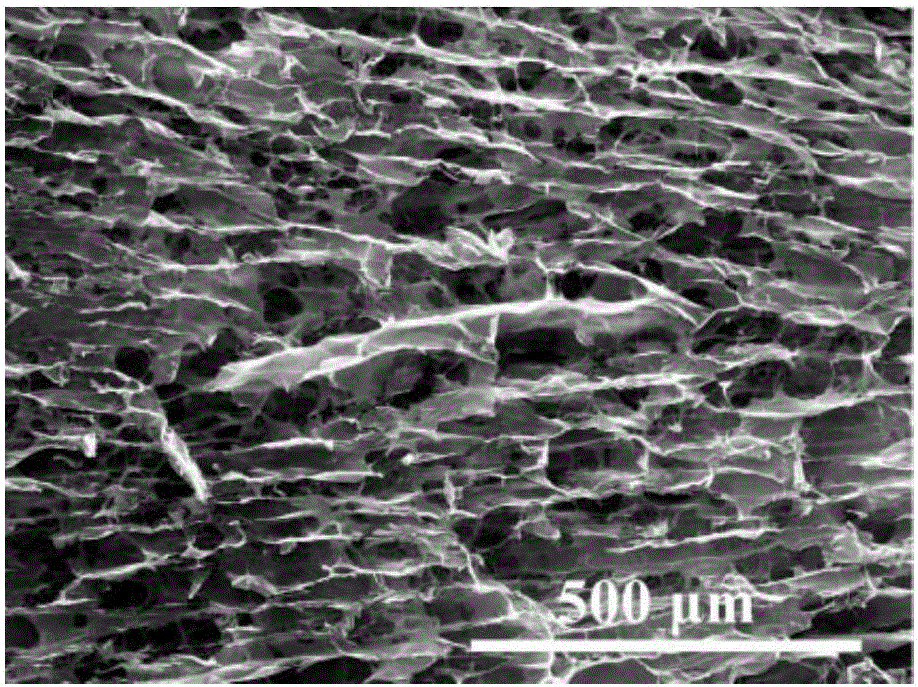

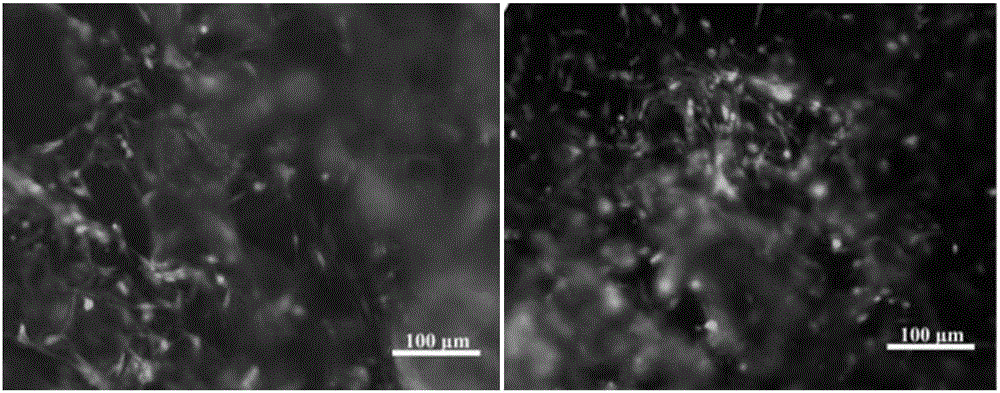

[0035] The embodiment of the present invention is a preparation method of a novel nerve repair tissue engineering scaffold, comprising:

[0036]The step of modifying bacterial cellulose; the step of preparing living cell-derived material; and uniformly mixing the modified bacterial cellulose and living cell-derived material, injecting into a mold, forming holes through ice crystal directional solidification, and freeze-vacuum drying Steps for preparing tissue engineering scaffolds for nerve repair.

[0037] Preferably, the step of the bacterial cellulose modification treatment comprises:

[0038] Step 1.1, pretreatment of bacterial cellulose; rinse the bacterial cellulose membrane with water several times to remove the medium and impurities on the surface of the membrane, and then soak the membrane in 0.01~0.5mol / L sodium hydroxide solution at 80-100°C Boil for 5 to 60 minutes to remove the bacteria and residual medium in the film. At this time, the film is milky white and tr...

Embodiment 1

[0060] A preparation method for a novel nerve repair tissue engineering scaffold, comprising:

[0061] Step 1: Take the bacterial cellulose membrane and cut it into a certain size according to the size of the mold, rinse it with clean water several times, remove the culture medium and impurities on the surface of the membrane, then soak the membrane in 0.1mol / L sodium hydroxide solution, boil at 90°C for 60min, Remove the bacteria and residual medium in the liquid film, and the film is milky white and translucent at this time; rinse with distilled water several times, and use pH test paper to lightly press the film to measure the pH value, which is about 7.1-7.5; the obtained BC film is dispersed by mechanical high-speed broken into flocculent fibers, and centrifuged to remove water for later use;

[0062] A 0.1 mol / L sodium periodate solution was prepared; the pretreated bacterial cellulose was soaked in the above sodium periodate solution, and stored in the dark for three da...

Embodiment 2

[0067] A preparation method for a novel nerve repair tissue engineering scaffold, comprising:

[0068] Step 1: Take the bacterial cellulose membrane and cut it into a certain size according to the size of the mold, rinse it with clean water several times, remove the culture medium and impurities on the surface of the membrane, then soak the membrane in 0.2mol / L sodium hydroxide solution, boil at 90°C for 30min, Remove the bacteria and residual culture medium in the liquid film. At this time, the film is milky white and translucent; rinse with distilled water several times, and use pH test paper to lightly press the film to measure the pH value, which is about 7.1-7.5. Disperse the obtained BC film with high speed mechanical broken into flocculent fibers, and centrifuged to remove water for later use;

[0069] Add bacterial cellulose flocculent fibers into isopropanol, prepare 20% sodium hydroxide in equimolar ratio to bacterial cellulose glucose unit, slowly add sodium hydroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com