Method for fabricating aerogels and their application in biocomposites

a biocomposites and aerogel technology, applied in the field of aerogel fabrication, can solve the problems of inability to fabricate biocomposites or bio-wrapping materials, high temperature and pressure conditions of supercritical fluid, and brittle structure, etc., and achieves easy separation, easy preparation, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

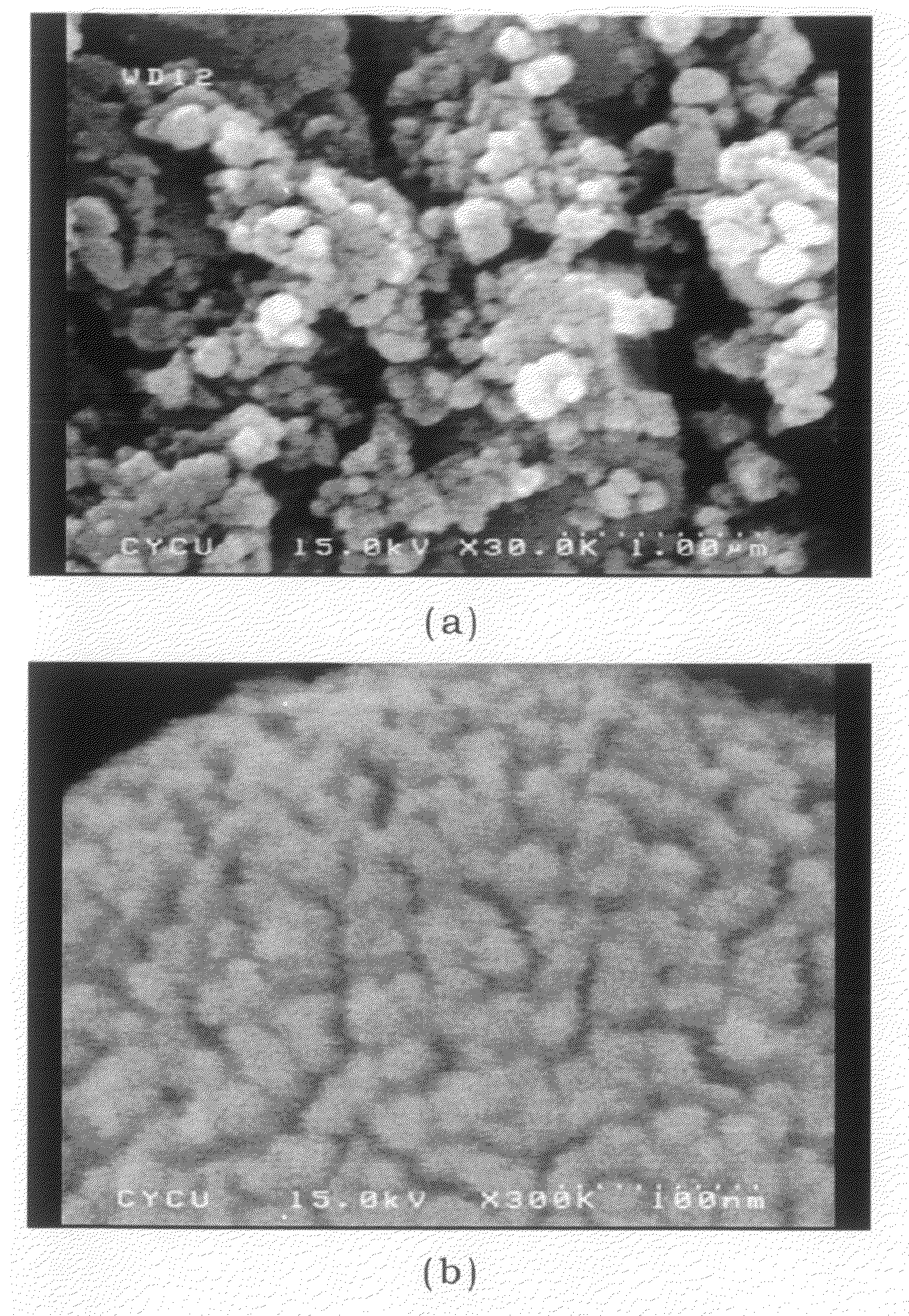

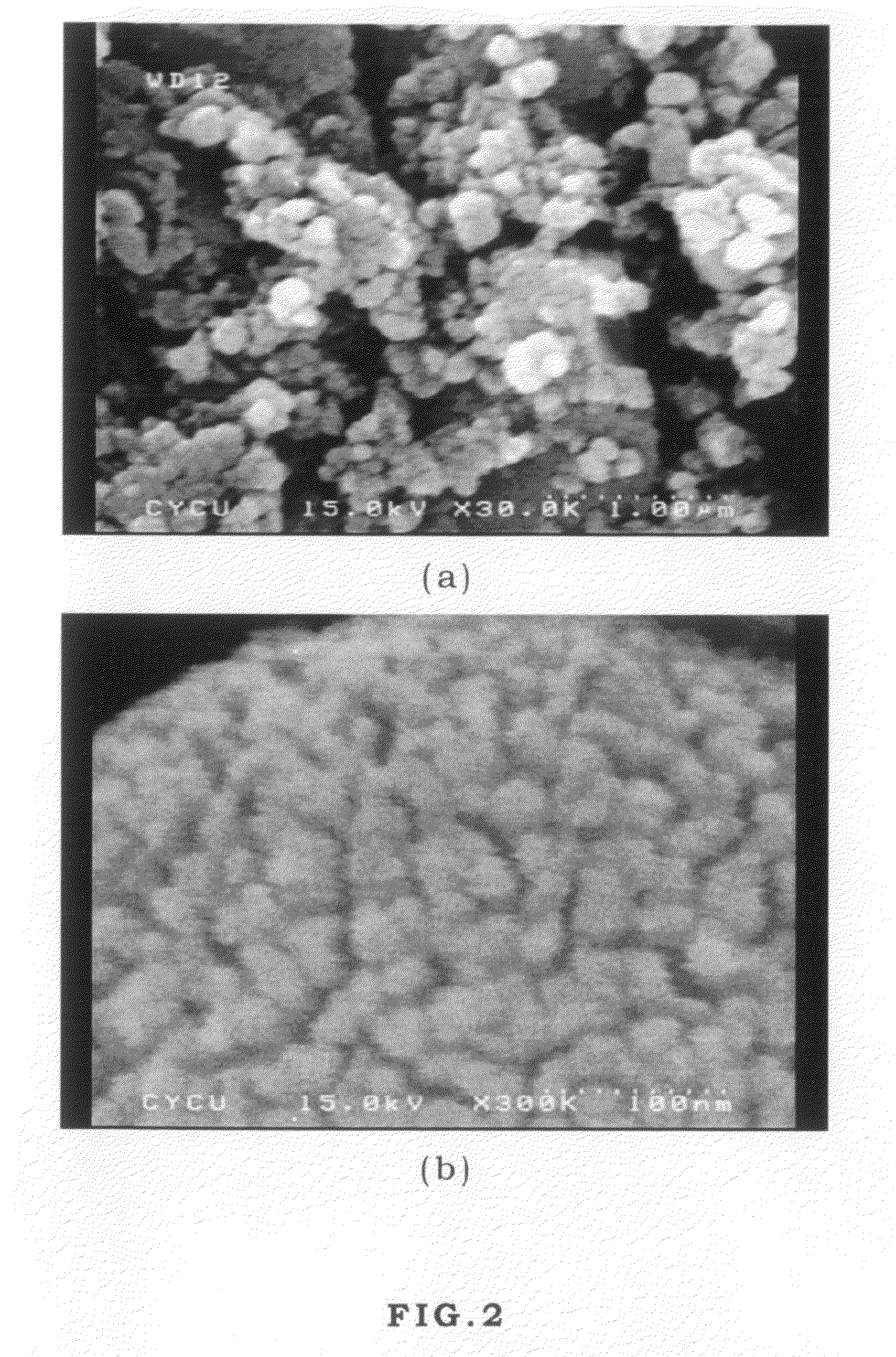

Image

Examples

first embodiment

[0018]In the present invention, a method for fabricating an aerogel is provided. At first, a precursor solution is provided and the precursor solution comprises an ionic liquid, a catalyzed hydrolysis and / or condensation reagent, and at least one alkoxide monomer and / or aryloxide monomer. The ionic liquid is used as a template as well as a solvent. The central element of the alkoxide monomer and / or aryloxide monomer comprises one selected from the group consisting of the following: Li, Na, K, Rb, Cs, Be, Mg, Ca, Sr, Ba, Ti, Te, Cr, Cu, Er, Fe, Ta, V, Zn, Zr, Al, Si, Ge, Sn, and Pb. The common alkoxide monomer and / or aryloxide monomer comprises one selected from the group consisting of the following: tetramethyl orthosilicate (TMOS), tetraethoxy orthosilicate (TEOS), bis(triethoxysilyl)ethane (BTSE), bis(triethoxysilyl)benzene (BTSB), tetrabutyl titanate (TBOT), and vanadium oxytriproposide. The catalyzed hydrolysis and / or condensation reagent comprises one selected from the group co...

second embodiment

[0029]In the present invention, a method for fabricating surface modified aerogel is provided. At first, an precursor solution is provided and the precursor solution comprises at least one alkoxide monomer and / or aryloxide monomer, a catalyzed hydrolysis and / or condensation reagent, an ionic liquid, and an alkoxide monomer and / or aryloxide monomer with at least one specific moiety. The ionic liquid is used as a template as well as a solvent. The specific moiety comprises one selected from the group consisting of the following: carboxyl group, mercapto group, amino group, diamino group, alkyl group (such as methyl group), aryl group (such as phenyl group), epoxy group, and cyano group. The catalyzed hydrolysis and / or condensation reagent comprises one selected from the group consisting of the following or any combination of the following: alcohol (the number of carbon is less than or equal to 5), acidic compound, and alkaline compound. Thus, the reagent catalyzes the hydrolysis and c...

third embodiment

[0041]In the present invention, a method for fabricating biocomposite is disclosed. Biocomposite can be applied in variety of fields, such as immobilized enzyme, drug controlled release, bio-separation technique, and sensors, etc.

[0042]The definition of “immobilized enzyme” is that enzyme is confined in a specific region but its active site is not hindered so that enzyme can be repeatedly used and continuously operated to thereby reduce the usage of the enzyme and to be effectively separated from the final product. There are numerous methods to immobilize enzyme, generally such as adsorption method, ionic bonding method, covalent bonding method, crosslinking method, and embedding method. Among these, since the covalent bonding method, fixing enzyme on a support, has the advantages of intense bonding force and high stability, it is the most common method for immobilizing enzyme. The immobilized enzyme has many advantages, such as being reusable, being quickly separated from the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com