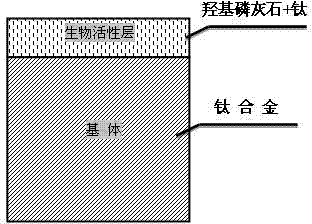

Hydroxyapatite activated titanium alloy surface-layer biological composite material and preparation method thereof

A technology of hydroxyapatite and composite materials, applied in medical science, prosthesis, etc., can solve problems affecting biological activity, nerve and physiological disorders, stress shielding, etc., and achieve improved interface bonding strength, good biocompatibility, Avoid the effect of easy cracking of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

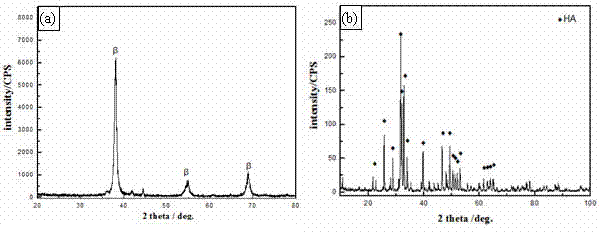

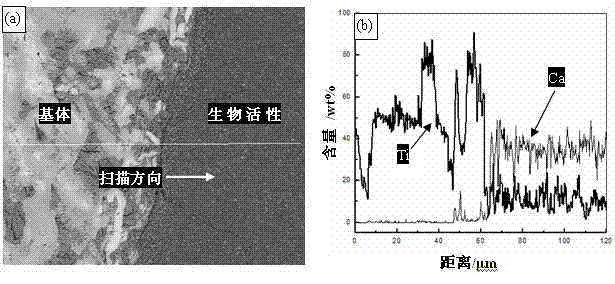

Examples

Embodiment 1

[0025] (1) Weigh Ti, Nb, and Zr metals with a purity of 99.5%, 99.95%, and 99% and an average particle size of 30 μm according to the mass percentage (wt%) of Ti 60%, Nb 34%, and Zr 6%. Powder; weigh 5.2g according to the mass percentage (wt%) of hydroxyapatite 85% (purity 97%, average particle size 100nm), Ti 15% (purity 99.5%, average particle size 30 μm).

[0026] (2) Put the titanium, niobium and zirconium powder weighed in step (1) into a ball milling tank, the ball milling medium is stainless steel balls, the ball to material ratio is 4:1, after sealing with alcohol, vacuumize to 20Pa, and carry out mechanical alloying for 7 hours Take it out, then place it in a vacuum drying oven and dry it at 40°C to obtain a titanium alloy matrix mixed powder; put the hydroxyapatite powder and titanium powder into a ball mill jar, the ball mill medium is stainless steel balls, and the ball-to-material ratio is 3: 1. After sealing with alcohol, evacuate to 20Pa, mix the powder for 1.5 ...

Embodiment 2

[0031] (1) According to the mass percentage (wt%) of Ti 74%, Nb 13%, and Zr 13.0%, respectively weigh Ti, Nb, and Zr metals with a purity of 99.5%, 99.95%, and 99%, and an average particle size of 25 μm Powder; weigh 3.1g according to the mass percentage (wt%) of hydroxyapatite 90% (purity 97%, average particle size 10 μm), Ti 10% (purity 99.5%, average particle size 25 μm).

[0032] (2) Put the titanium, niobium and zirconium powder weighed in step (1) into a ball milling tank, the ball milling medium is stainless steel balls, the ball to material ratio is 3:1, after sealing with alcohol, vacuumize to 30Pa, and perform mechanical alloying for 6 hours Take it out, then place it in a vacuum drying oven and dry it at 40°C to obtain a titanium alloy matrix mixed powder; put the hydroxyapatite powder and titanium powder into a ball mill jar, the ball mill medium is stainless steel balls, and the ball-to-material ratio is 4: 1. After sealing with alcohol, vacuumize to 30Pa, mix the...

Embodiment 3

[0036] (1) According to the mass percentage (wt%) of Ti 67%, Nb 29%, and Zr 4%, respectively weigh Ti, Nb, and Zr metal powders with a purity of 99.5%, 99.95%, and 99%, and an average particle size of 45 μm Weigh 4.03g according to the mass percentage (wt%) of hydroxyapatite 95% (purity 97%, average particle size 20nm), Ti 5% (purity 99.5%, average particle size 45μm).

[0037] (2) Put the titanium, niobium and zirconium powder weighed in step (1) into a ball milling tank, the ball milling medium is stainless steel balls, the ball to material ratio is 4:1, after sealing with alcohol, vacuumize to 25Pa, and perform mechanical alloying for 8 hours Take it out, then place it in a vacuum drying oven and dry it at 40°C to obtain a titanium alloy matrix mixed powder; put the hydroxyapatite powder and titanium powder into a ball mill jar, the ball mill medium is stainless steel balls, and the ball-to-material ratio is 3: 1. After sealing with alcohol, vacuumize to 25Pa, mix the powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com