Electric heating furnace

An electric heating furnace and furnace body technology, applied in the field of electric heating furnaces, can solve the problems of single cooling fan function, hot furnace shell, large heat loss, etc., to improve the safety and stability of use, and the flow of wind is smooth and accurate. , the effect of reducing the surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

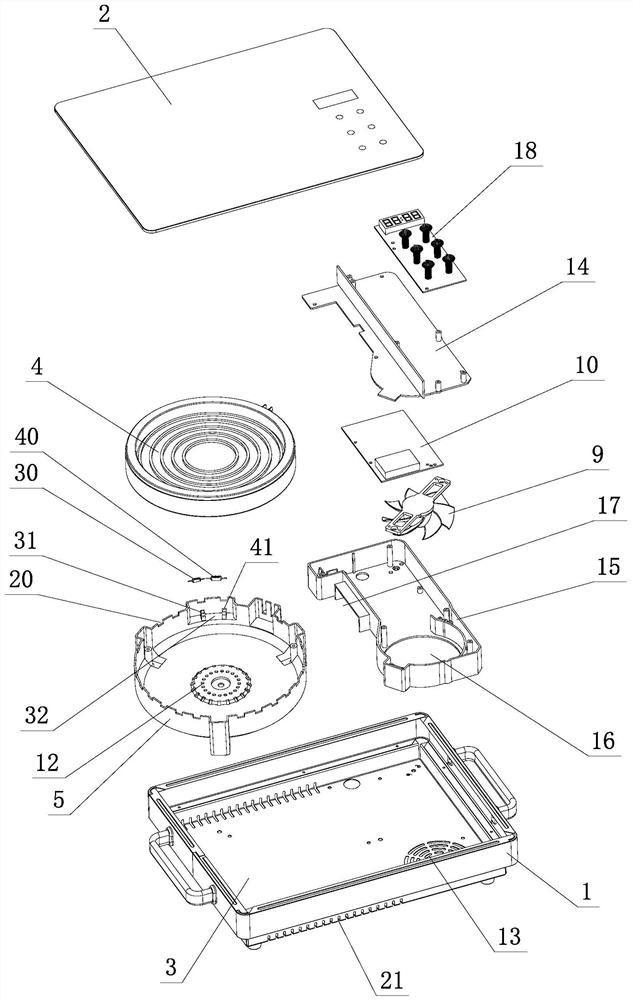

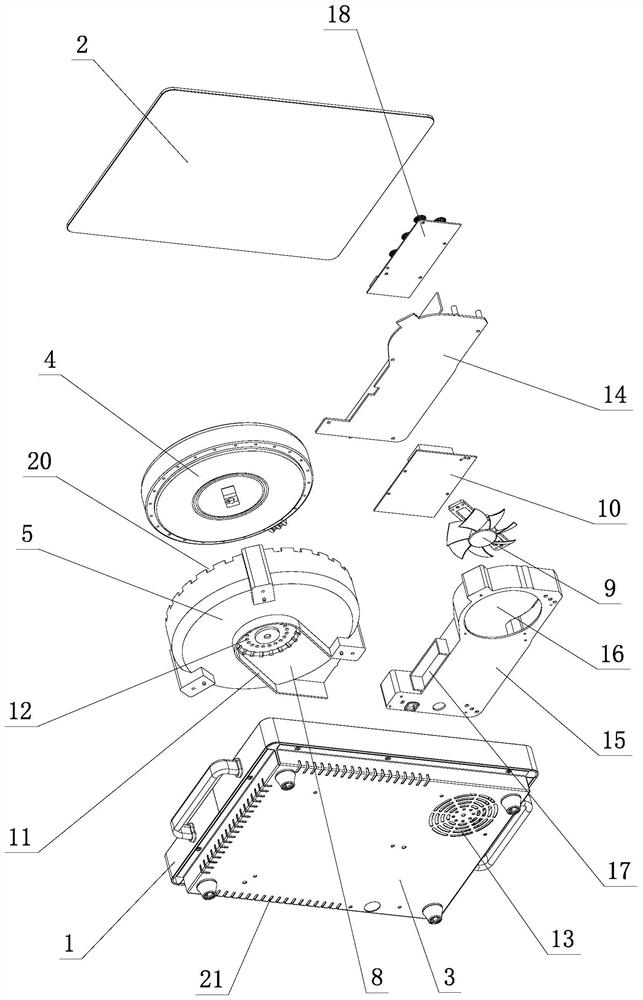

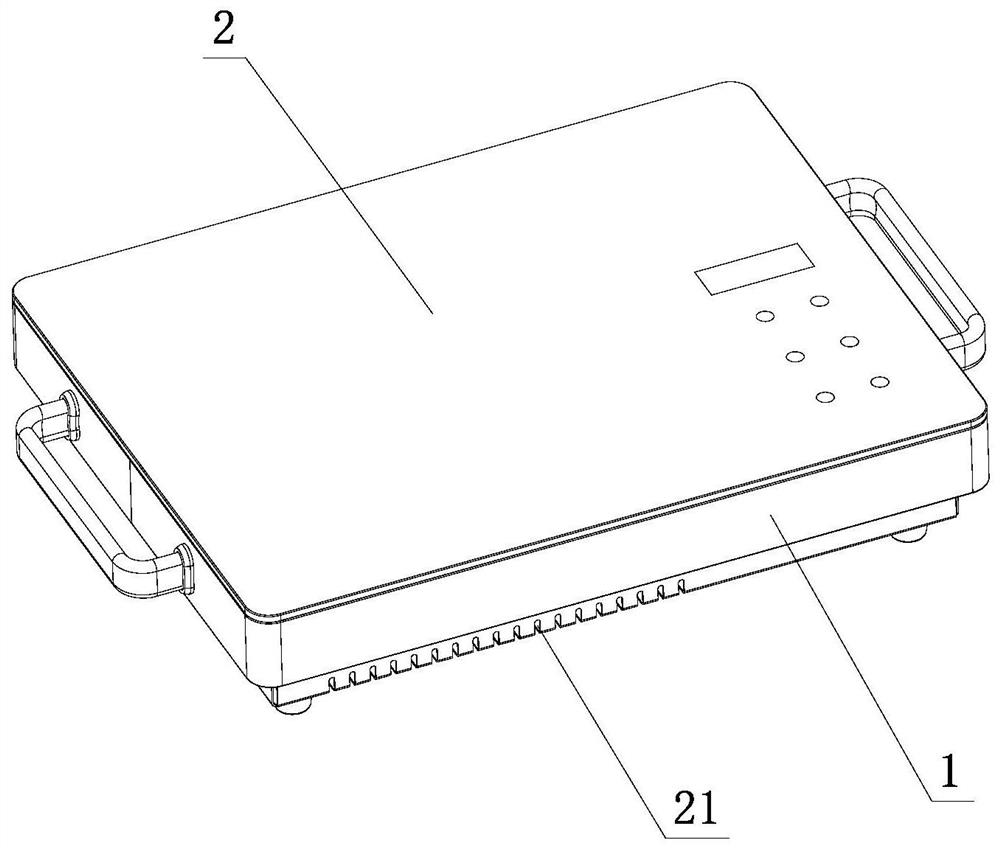

[0067] see Figure 1-Figure 6 , the electric furnace includes a furnace body 1, and a panel 2 and a bottom plate 3 respectively arranged on the upper and lower positions of the furnace body 1, and a heating element 4 and a heat recovery cover 5 are arranged in the furnace body 1; the heating element 4 is located on the panel 2 Below; the top of the heat recovery cover 5 is provided with an opening, and a heat insulating cavity 7 is formed to cover the periphery of the heating element 4; the heat recovery cover 5, the furnace body 1 and the bottom plate 3 form a wind flow channel, The wind flow channel communicates with the heat insulation cavity 7, and a cooling fan 9 and a main control board 10 are arranged therein.

[0068] The heat dissipation fan 9 draws the wind outside the furnace body 1 into the air flow channel, and first dissipates heat to the main control board 10, and then introduces it into the heat insulation chamber 7, takes away the heat leaked from the heating ...

no. 2 example

[0109] see Figure 7 , this electric furnace, it is different from the first embodiment in that:

[0110]The bottom plate 3 is provided with several air exhaust holes 21, these several air exhaust holes 21 are arranged on one side of the bottom plate 3, and the air induction hole 13 is arranged on the other side of the bottom plate 3, and forms a certain distance with the air exhaust holes 21 .

[0111] The wind in the heat insulation cavity 7 is exhausted outside the furnace body 1 through the cooperation of the air outlet 20, the cooling cavity 19, and the exhaust hole 21 in order to realize the single-bottom exhaust of the electric furnace.

[0112] Among them, the flow process of wind is as Figure 7 indicated by the arrow.

[0113] Others are not described in the first embodiment.

no. 3 example

[0115] see Figure 8 , this electric furnace, it is different from the first embodiment in that:

[0116] The side of the furnace body 1 is provided with several exhaust holes 21, and these several exhaust holes 21 are arranged at the upper position, or the middle position, or the lower position of the side portion of the furnace body 1, and the air induction hole 13 is arranged at the side of the bottom plate 3 , and form a certain distance with the exhaust hole 21 .

[0117] The wind in the heat insulation cavity 7 is exhausted outside the furnace body 1 through the cooperation of the air outlet hole 20, the cooling cavity 19, and the exhaust hole 21 in order to realize the unilateral exhaust of the electric furnace.

[0118] Among them, the flow process of wind is as Figure 8 indicated by the arrow.

[0119] Others are not described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com