Method for eliminating temperature gradient in metal strip sample heat treatment test

A technology of temperature gradient and metal strip, applied in the field of metal heat treatment, can solve the problems of large temperature gradient, huge equipment, high price, etc., and achieve the effect of increasing the length of the uniform temperature zone, reducing the production cost, and improving the test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The method of the present invention is adopted in the continuous annealing simulation test machine for cold-rolled strip steel, specifically as follows.

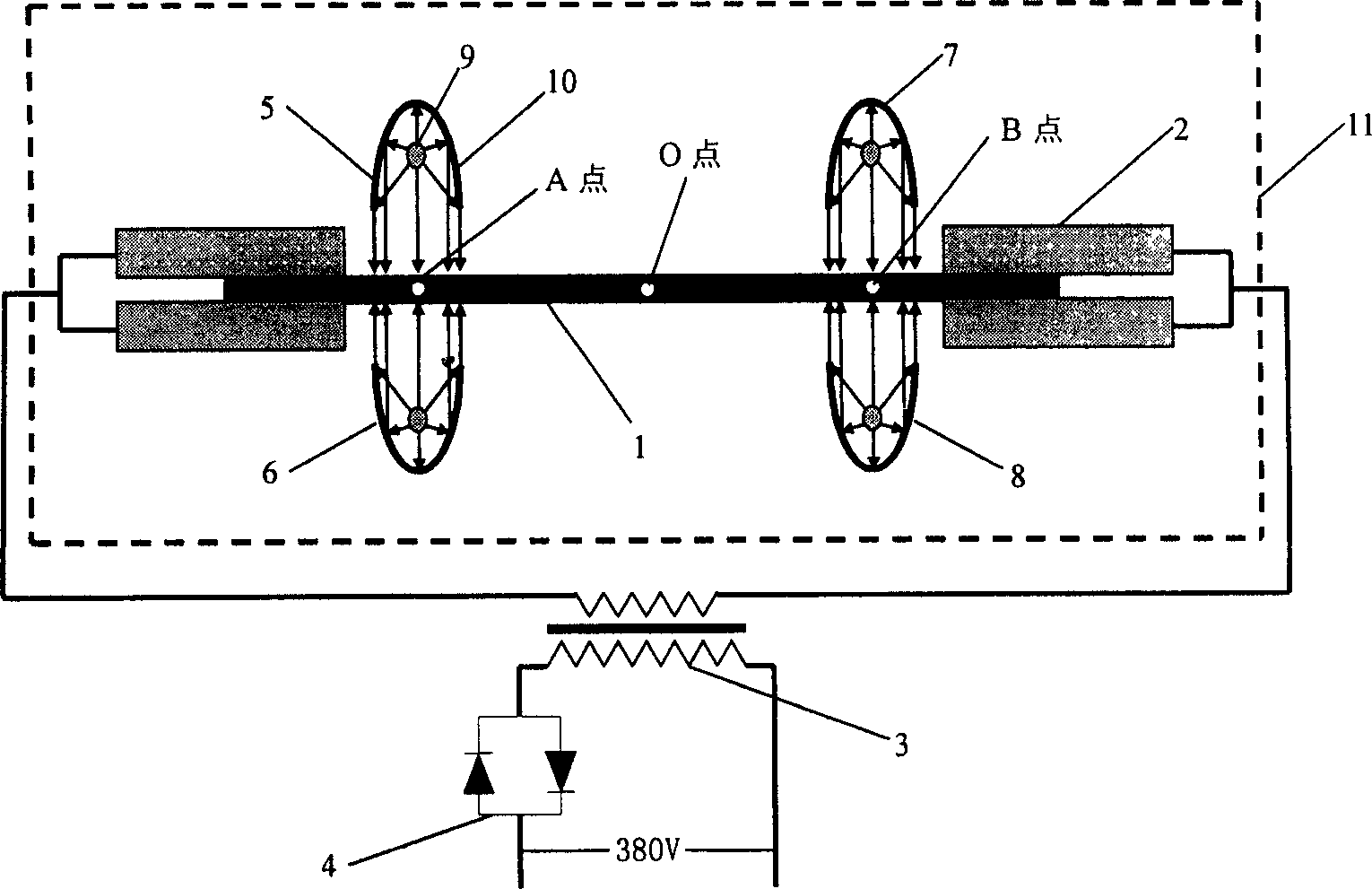

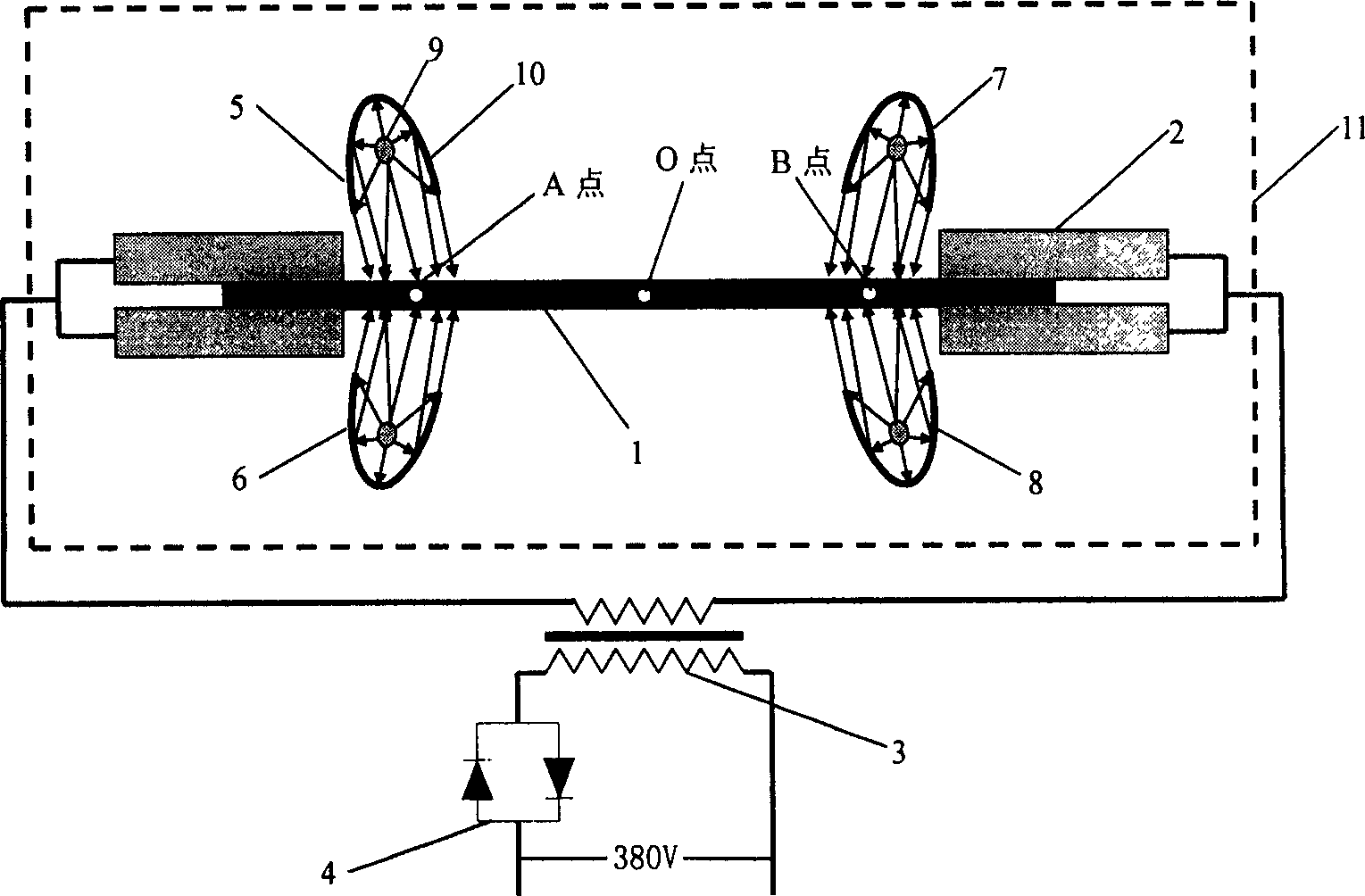

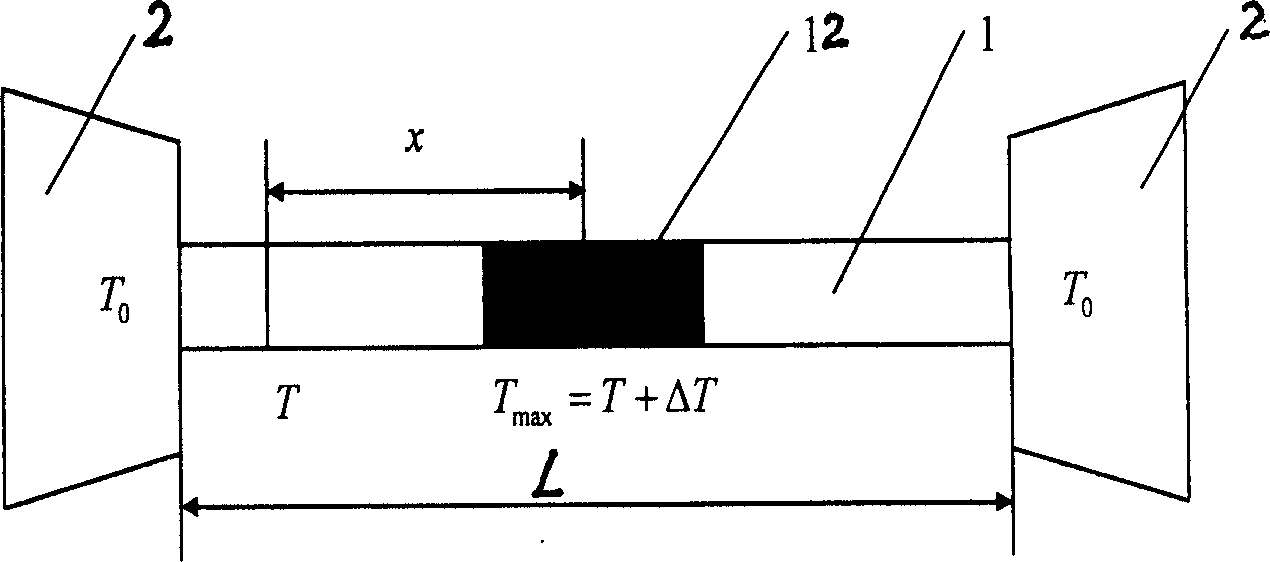

[0016] Such as figure 1 As shown, the sample 1, the fixture 2, the infrared heating device 5, 6, 7, and 8 are all placed in the operation box 11, and the operation box 11 can be vacuumed or filled with various protective atmospheres; the fixture 2 and the heating transformer 3 20×100mm copper bars are used to connect the sub-stages. Sample 1 is a cold-rolled steel strip of 1.0×300×560mm. 50mm at both ends are clamped in fixture 2. The width of the opening of reflector 10 is 50mm. , the reflection cover 10 is fixed on the wall of the operation box 11, vertically and symmetrically arranged on the sample 1, the distance between the opening and the surface of the sample 1 is 100mm, and the distance between the outermost edge and the fixture 2 is 30mm, the infrared heating device 5,6 and the infrared light-emitting lamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com