Heat exchanger and refrigeration cycle device provided with heat exchanger

A technology of heat exchangers and heat exchange units, applied in heat exchange equipment, compressors with reversible cycles, refrigerators, etc., can solve the problems of heat exchanger temperature efficiency reduction, leakage, etc., and achieve the effect of reducing heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

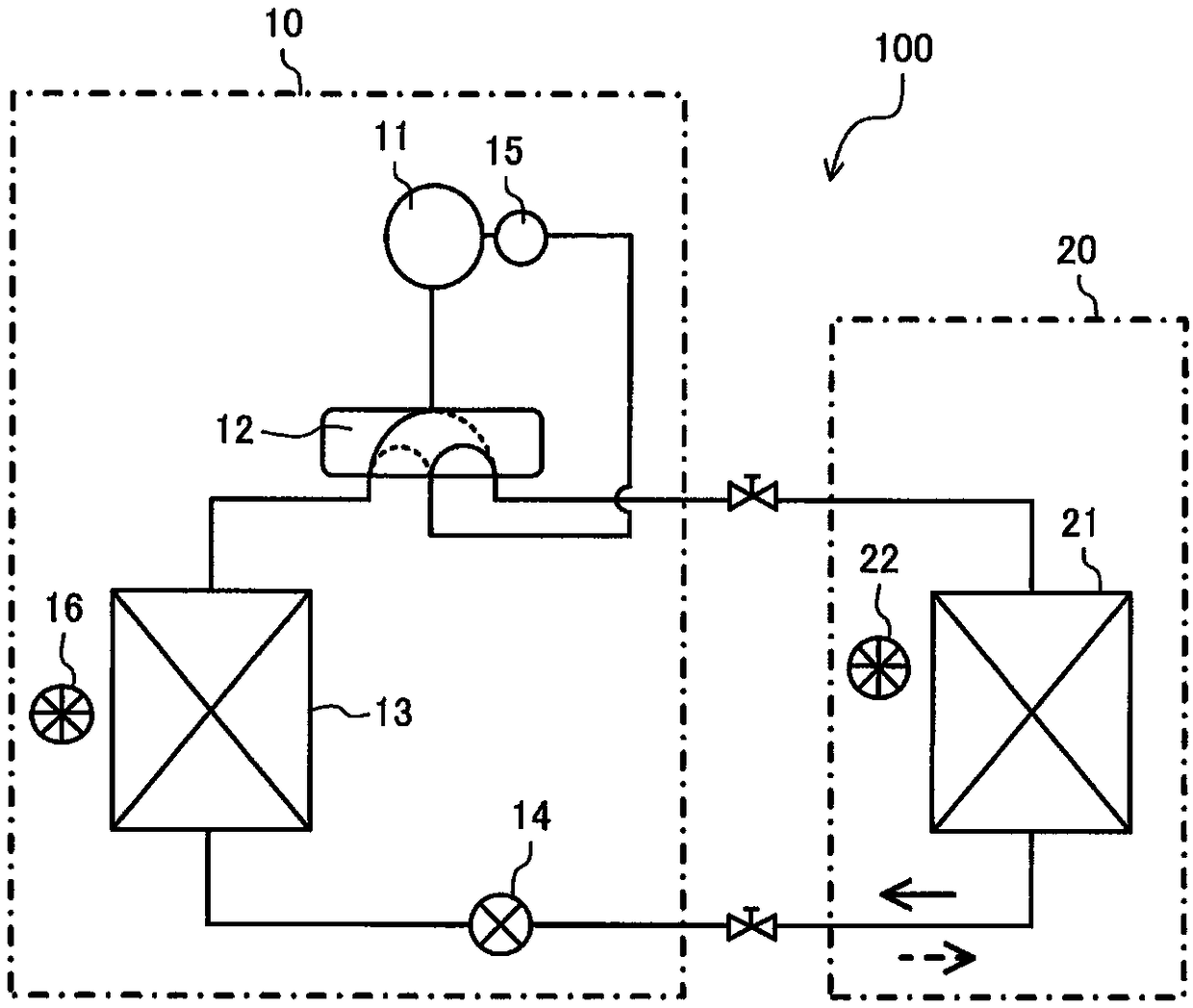

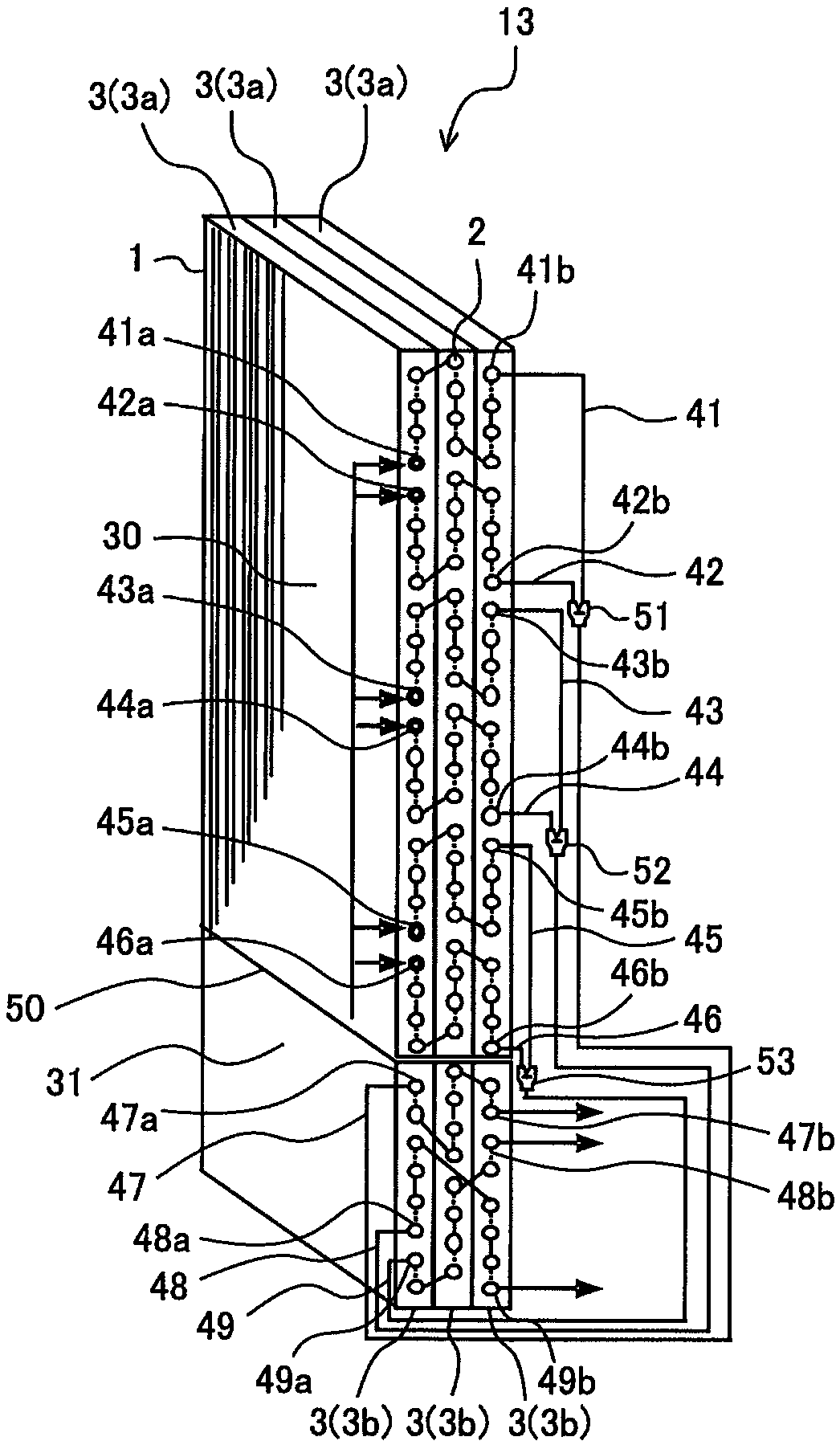

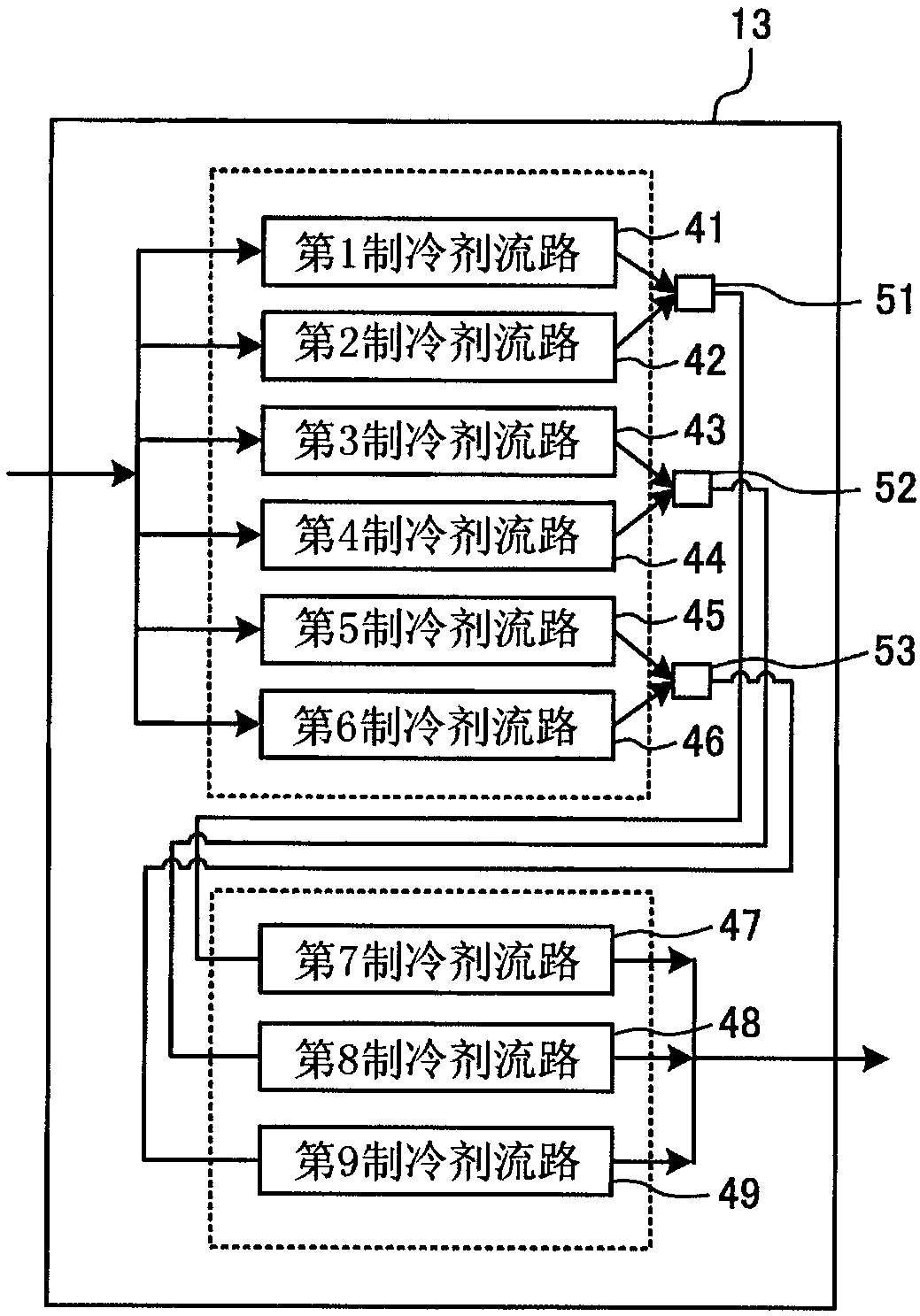

[0019] figure 1 It is a block diagram of an air conditioner equipped with the heat exchanger of Embodiment 1 of this invention. In addition, in figure 1 Here, the solid arrow indicates the flow direction of the refrigerant during the heating operation, and the broken line arrow indicates the flow direction of the refrigerant during the cooling operation.

[0020] Such as figure 1 As shown, the air conditioner 100 including the heat exchanger according to Embodiment 1 includes an outdoor unit 10 and an indoor unit 20.

[0021] The outdoor unit 10 includes a compressor 11 for compressing refrigerant, a four-way valve 12, an outdoor side heat exchanger 13, a pressure reducing device 14, an accumulator 15, and an outdoor side blower 16.

[0022] The compressor 11 sucks in the refrigerant and compresses the refrigerant to a high temperature and high pressure state. The compressor 11 may be a compressor capable of variable operating capacity (frequency), or a compressor of constant capaci...

Embodiment approach 2

[0059] In the first embodiment described above, the number of rows of the heat exchange units 3 is the same in the upstream side heat exchanger 30 and the downstream side heat exchanger 31. However, in the second embodiment, the number of rows of the heat exchange units 3 is the downstream side heat exchanger 31. The configuration in which the number of rows of 3 is smaller than that of the upstream side heat exchanger 30 can reduce the number of heat transfer tubes 2 through which the liquid refrigerant passes. Hereinafter, the description will be focused on the configuration different from Embodiment 2 and Embodiment 1. The structure not described in the second embodiment is the same as the first embodiment.

[0060] Figure 4 It is a schematic perspective view of the outdoor side heat exchanger 13A of Embodiment 2 of this invention.

[0061] The outdoor side heat exchanger 13A of the second embodiment and figure 2 Compared with the outdoor heat exchanger 13 of the first embodi...

Embodiment approach 3

[0076] In the above-mentioned first and second embodiments, the fin pitch, which is the width between the fins, is made the same in the upstream side heat exchanger and the downstream side heat exchanger, but in the third embodiment, the The fin pitch is smaller than that of the upstream heat exchanger. Hereinafter, the description will focus on the differences between the third embodiment and the second embodiment. The structure not described in the third embodiment is the same as that of the second embodiment.

[0077] Image 6 It is a dimensional explanatory diagram of the outdoor heat exchanger 13B in Embodiment 3 of the present invention. in Image 6 In the figure, the interval between adjacent heat sinks 1 is enlarged for convenience of explanation.

[0078] In the outdoor heat exchanger 13B of Embodiment 3, the fin pitch of the fin 1 of the upstream heat exchange unit 3a is set to E, and the fin pitch of the fin 1 of the downstream heat exchange unit 32b is set to F Below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com