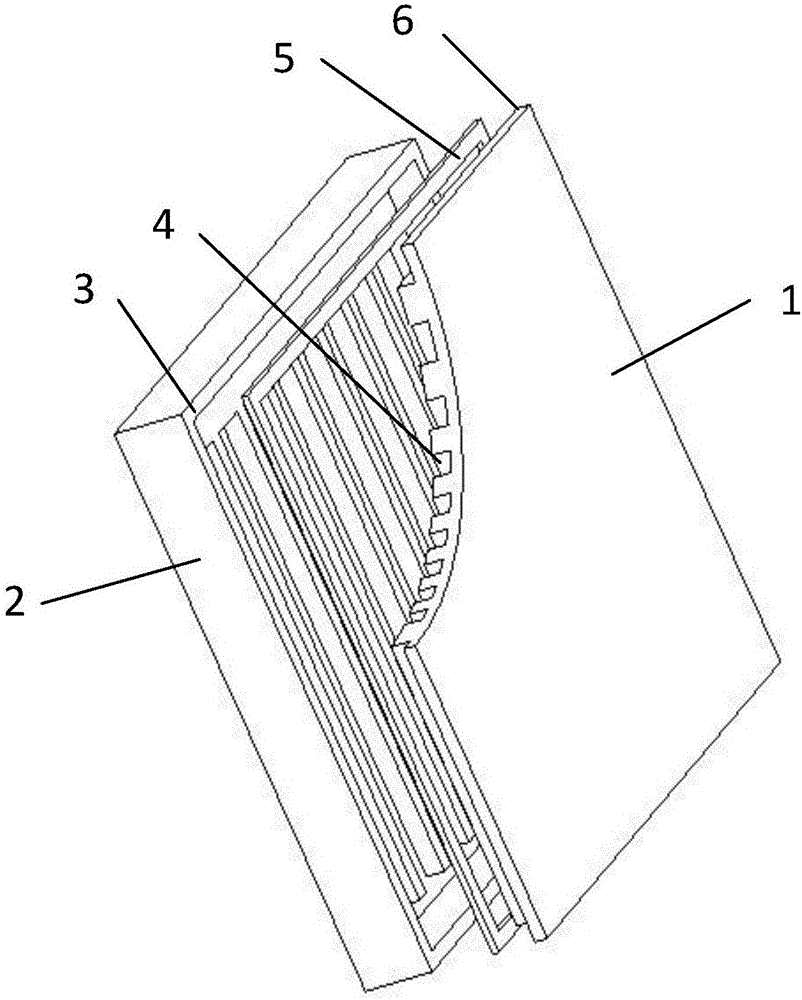

Flat plate type loop heat pipe evaporator and loop heat pipe

A loop heat pipe and evaporator technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as difficult startup, large reverse heat conduction effect, and blocked liquid return, so as to increase roughness and reduce operation failure Risk, the effect of reducing the reverse heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

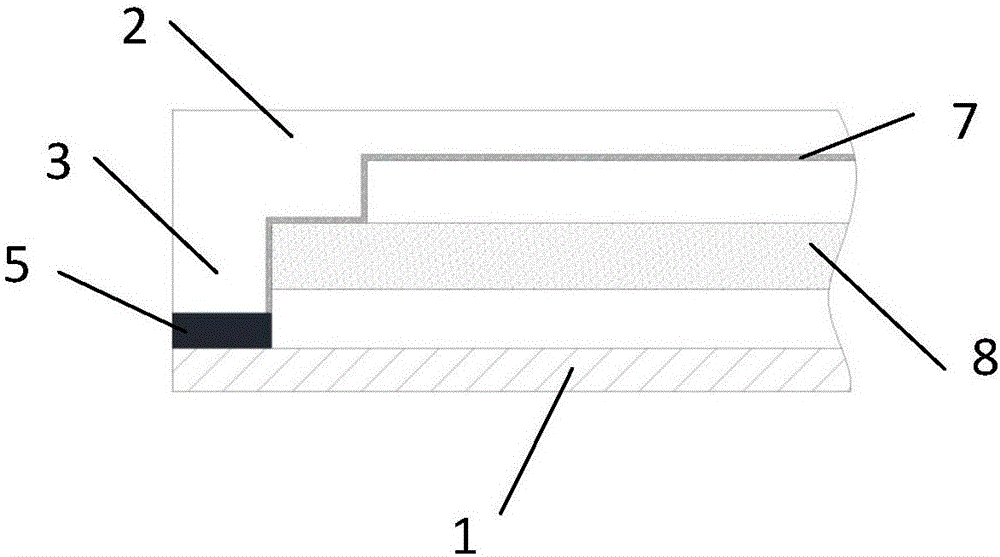

[0035] The heat-insulating barrier 7 and the heat-insulating layer 5 of the inner wall of the liquid storage chamber 2 are prepared by spraying by plasma spraying, first spraying Ni(Al) with a thickness of 30 microns as the bonding layer, and then continuing to spray Ni(Al) with a thickness of 150 microns on it. The aluminum coating is used as the heat insulating layer 7, and its surface roughness is 15 μm. The steam channel bottom plate 1 of the evaporator and the liquid storage chamber 2 are sealed and connected by laser welding. The working medium is pure water.

[0036] After adopting the evaporator of the present invention, in the working environment of the evaporator steam channel bottom plate 1 at 70°C, the heat insulation layer 5 and the heat insulation spacer 7 can reduce 80-90% of the heat leakage generated through the side wall, and the loop heat pipe It can not only start smoothly, but also work stably for a long time.

Embodiment 2

[0042] In analogy to Example 1, only the heat insulating layer 7 and the heat insulating layer 5 are changed to MCrAlY with a thickness of 50 μm as the bottom bonding layer, and zirconia with a thickness of 200 μm as the heat insulating layer, and the rest of the preparation method is the same as that of Example 1.

[0043] The loop heat pipe adopted by the invention can start smoothly and work stably for a long time in an environment of 60-80 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com