An electric lock for operating a circuit

An operation loop and electrical lock technology, applied in the field of electrical locks, can solve the problems of increasing the number and cost of components, increasing the risk of operation failure, etc., and achieve the effect of reducing the total volume, reducing the risk of operation failure, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

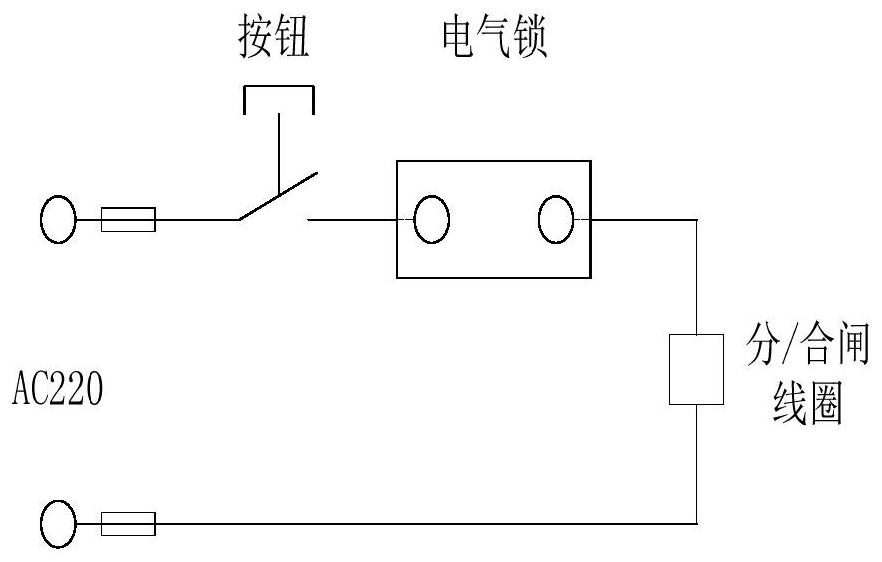

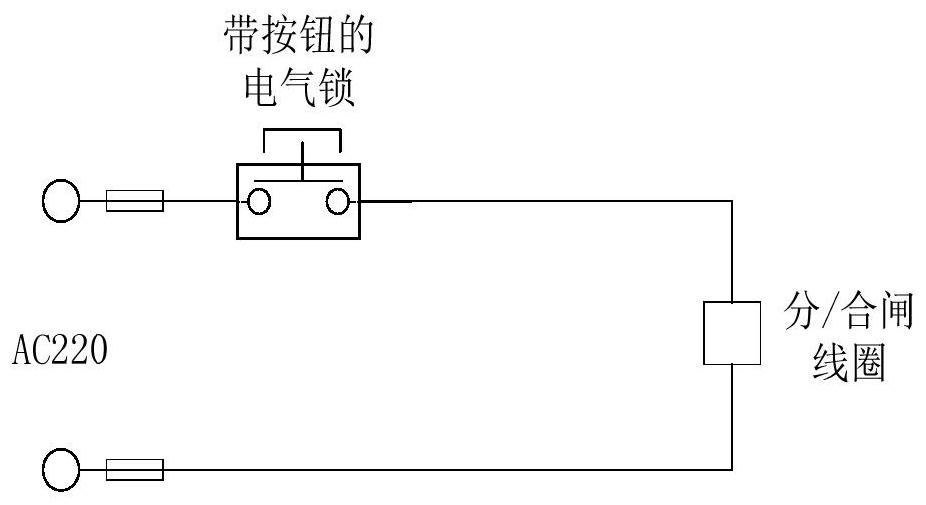

Problems solved by technology

Method used

Image

Examples

Embodiment 1

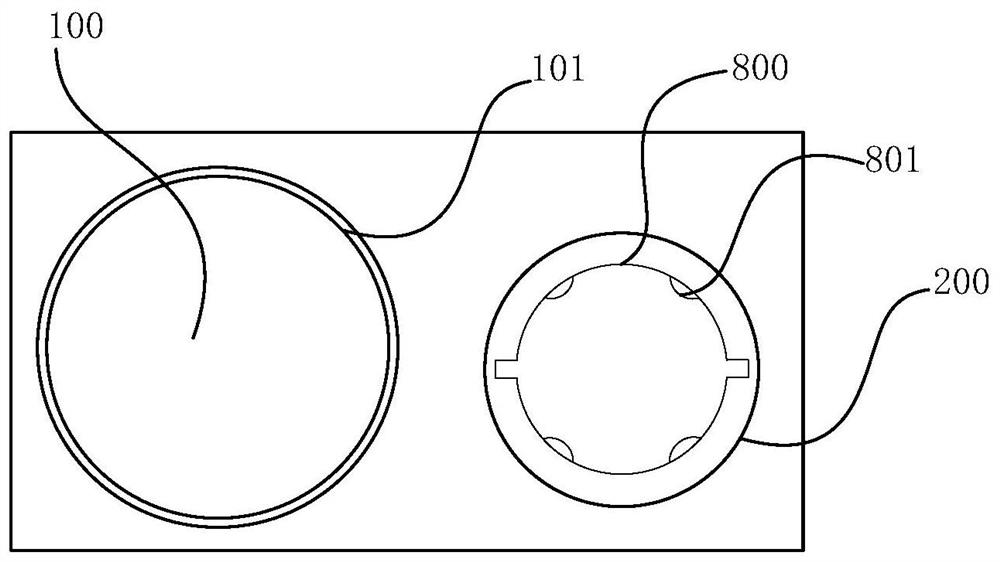

[0050] like figure 2 , 3 , 4, 5, 6, an electrical lock for operating circuits, including:

[0051] housing 900,

[0052] The movable contact group 400, located in the housing 900, includes at least one conductor 403;

[0053] The static contact group 500, located in the housing 900, includes a first static contact 501 and a second static contact 502, and the first static contact 501 and the second static contact 502 are respectively connected to the operation Both ends of the loop to be turned on;

[0054] The elastic component 700 is arranged between the movable contact group 400 and the static contact group 500;

[0055] The button assembly 100 includes a button cap 101 and a pressing rod 102 , the button cap 101 is disposed on the top of the pressing rod 102 and at least partially outside the housing 700 , and the button assembly 100 passes through the button cap 101 and the pressing rod 102 transmits the external mechanical force to the movable contact group 400;

[0...

Embodiment 2

[0065] like figure 2 , 7 , 8 and 9, an electrical lock for operating circuits, including:

[0066] housing 900,

[0067] The movable contact group 400, located in the housing 900, includes at least one conductor 403;

[0068] The static contact group 500, located in the housing 900, includes a first static contact 501 and a second static contact 502, and the first static contact 501 and the second static contact 502 are respectively connected to the operation Both ends of the loop to be turned on;

[0069] The elastic component 700 is arranged between the movable contact group 400 and the static contact group 500;

[0070] The button assembly 100 includes a button cap 101 and a pressing rod 102 , the button cap 101 is disposed on the top of the pressing rod 102 and at least partially outside the housing 700 , and the button assembly 100 passes through the button cap 101 and the pressing rod 102 transmits the external mechanical force to the movable contact group 400;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com