Heat dissipation performance test system and method of water-cooling heat sink

A technology of water-cooled radiators and testing systems, which is applied to the testing of machines/structural components, instruments, and measuring devices. It can solve problems such as insufficient heat dissipation power of radiators, increase overall costs, and burn components, etc., to reduce testing costs. Ensure the correct selection and working life, test the effect of safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

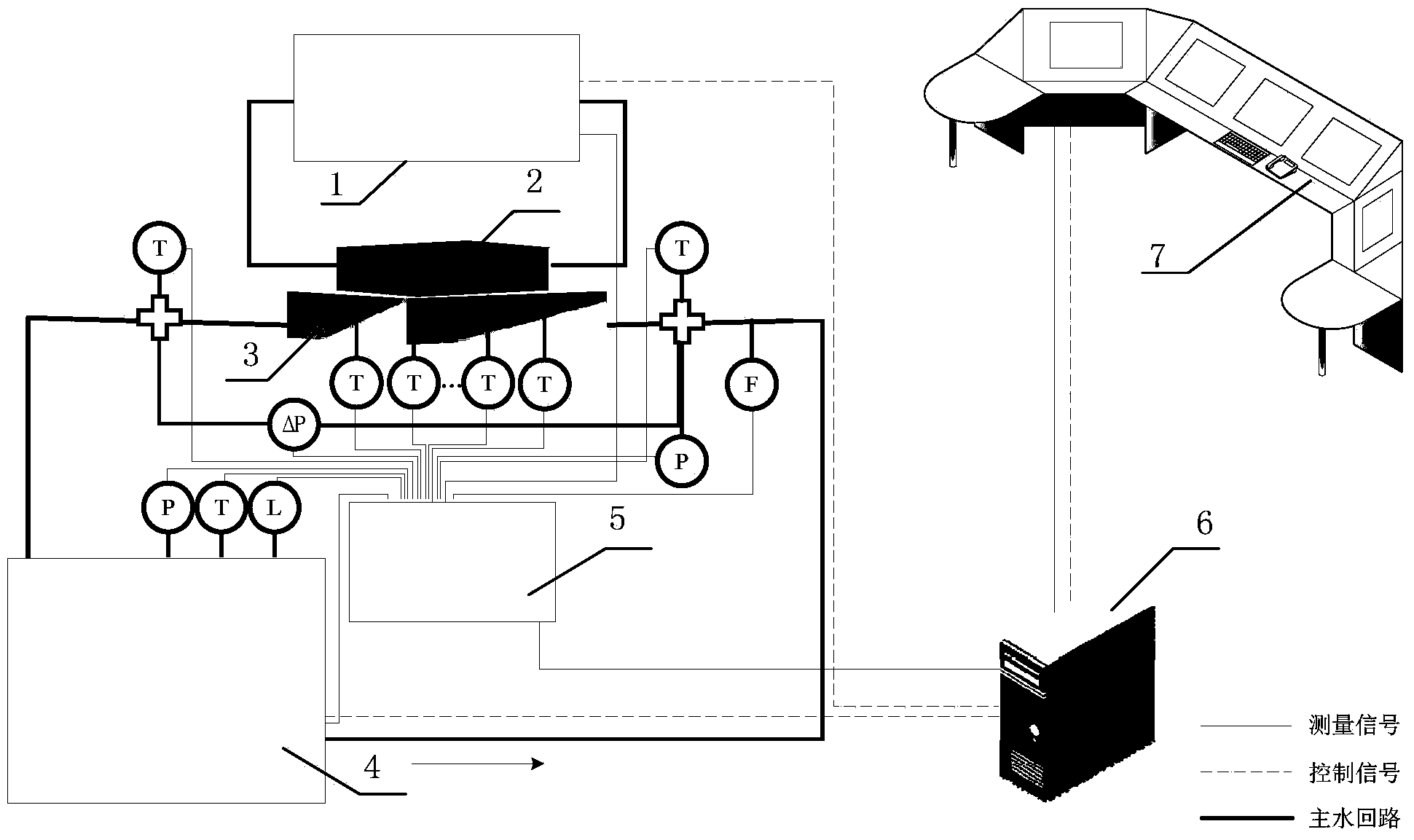

[0031] In this embodiment, the heat dissipation performance test system of a water-cooled radiator is taken as an example, as figure 1 As shown, the heat dissipation performance test system of the water-cooled radiator provided by the embodiment of the present invention includes: a power supply unit 1, a heating device 2, a tested water-cooled radiator 3, a water supply unit 4, a data acquisition unit 5, an industrial computer 6, and a control unit 7 , flow controller F, pressure sensor P, differential pressure sensor ΔP, temperature sensor T, liquid level sensor L.

[0032] The power supply unit 1 and the heating device 2 are connected to form a circuit. The power supply unit 1 uses an AC power supply to supply power to the heating device 2, and at the same time uses a DC power supply to collect the temperature data of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com