Storage tank for a cryogenic liquid and method of re-filling same

一种低温液体、重新填充的技术,应用在容器填充方法、容器排放的方法、气体处理/储存目的等方向,能够解决不是同样有效等问题,达到小泄漏可能、降低制造成本、降低热泄漏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

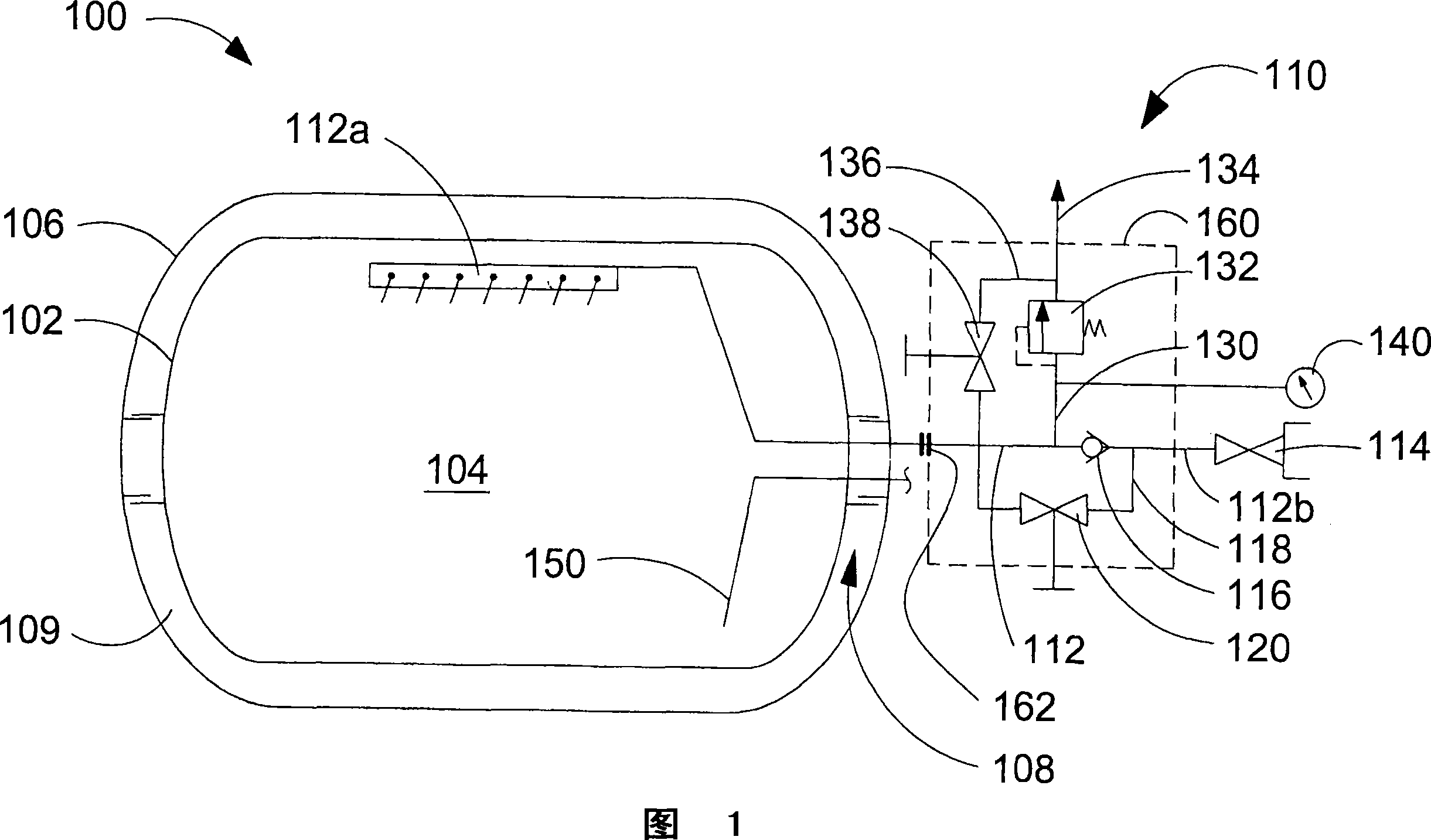

[0032] Referring to the schematic illustration of FIG. 1, a storage tank 100 includes an inner vessel 102 defining a cryogen space 104, an outer shell 106 surrounding the inner vessel 102, and a support structure 108 for keeping the inner vessel 102 separate from the outer shell 106, whereby the inner vessel 102 An insulating space 109 is defined between 102 and housing 106 .

[0033] The combined charge and exhaust assembly 110 includes a conduit 112 having a first end 112a having at least one opening disposed in an upper portion of the cryogen space and a second end 112b at the outer shell 106 and connect to jack 114. When filling a storage tank for cooling liquid, usually a portion of the cryogen space is left for vapor. Completely filling the cryogen space 104 with liquid will result in a very short hold time before the vapor is vented from the cryogen space 104 to reduce the vapor pressure. This is because even a small amount of heat leakage into the cryogen space 104 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com