Gravity-assisted loop heat pipe with ultrasonic vibration atomizing device

A technology of atomization device and ultrasonic vibration, which is used in circuits, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of lack of liquid working medium, low critical heat flux density, affecting heat exchange performance, etc., and achieve heat exchange performance. The effect of improving the heat flux density of the critical heat exchange, avoiding the contact thermal resistance, and reducing the hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

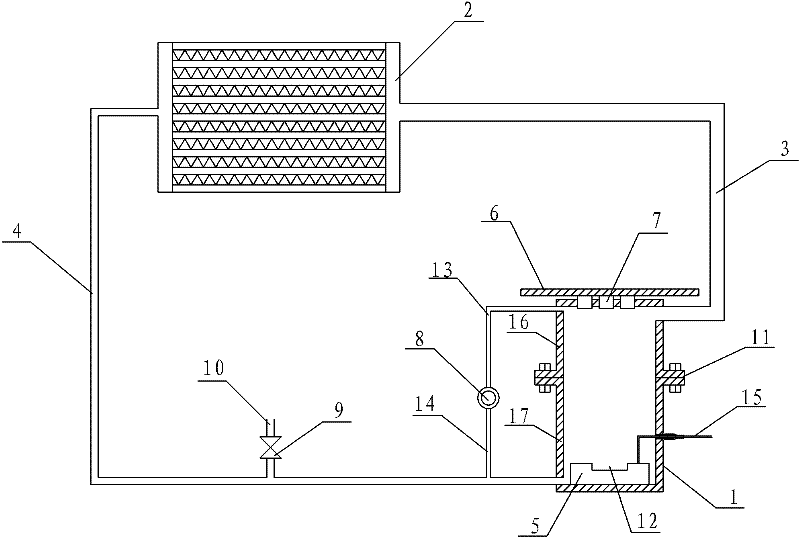

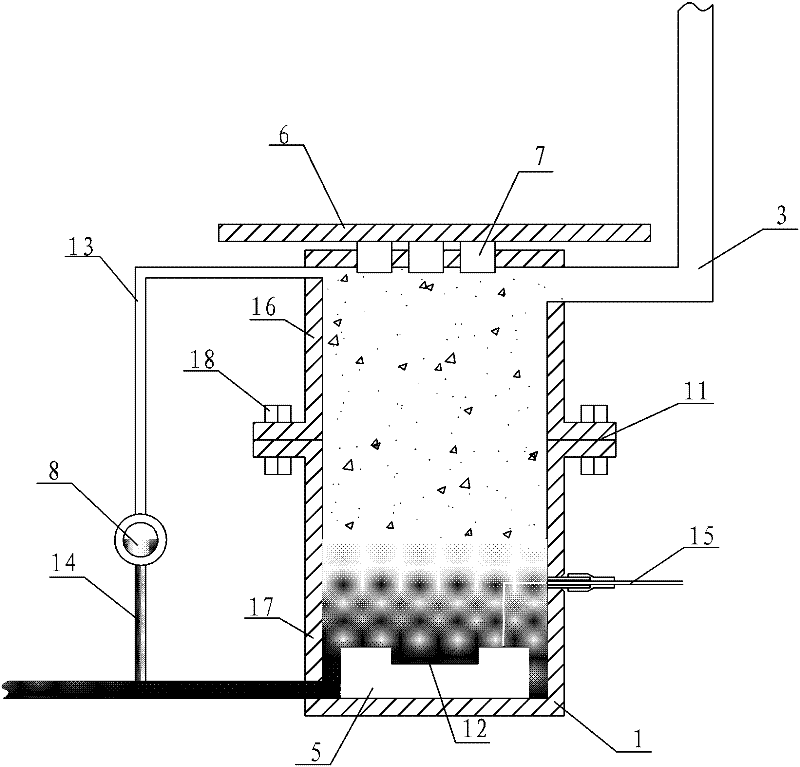

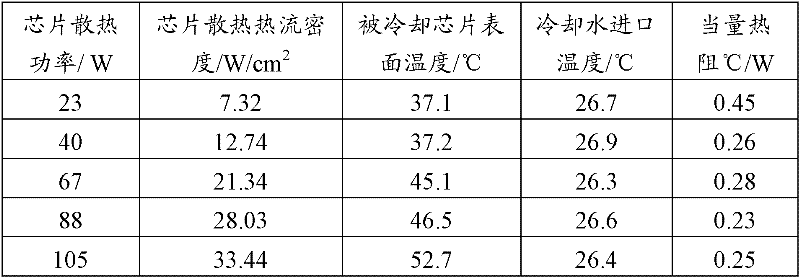

[0033] like figure 1 and figure 2 As shown, a gravity-assisted loop heat pipe with an ultrasonic vibration atomization device includes an evaporation chamber 1, a condensation section 2, and a gas phase tube 3 connecting the working medium outlet of the evaporation chamber 1 and the working medium inlet of the condensation section 2, and the condensation section The working medium outlet of 2 is connected with the working medium inlet of evaporation chamber 1 through a liquid phase tube 4; an ultrasonic vibration atomization device 5 is installed at the bottom of the inner cavity of evaporation chamber 1, and an atomization sheet is installed on the upper surface of the ultrasonic vibration atomization device 5 12. There are a number of notches corresponding to the position and shape of the cooled chip 7 on the top wall of the evaporation chamber 1. After being packaged by the cooled chip 7, one end surface is fixed on the silicon substrate 9, and the other end surface passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com